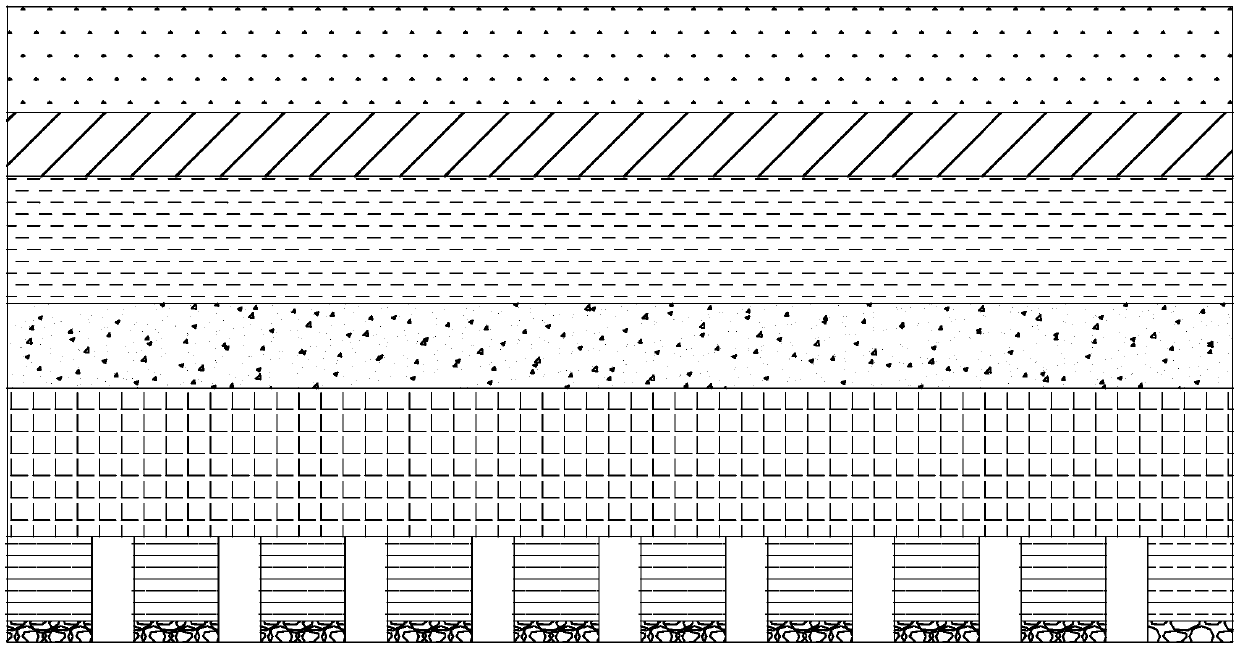

Strip type coal mining method in roof cutting filling close-to-gob areas

A coal mining method and strip-type technology, which are applied in surface mining, earthwork drilling, underground mining, etc., can solve the problems of destroying land resources and groundwater resources, increasing the economic burden of coal mines, increasing investment, etc., and achieving simple support. The effect of safety, control of surface subsidence, and reduction of filling costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

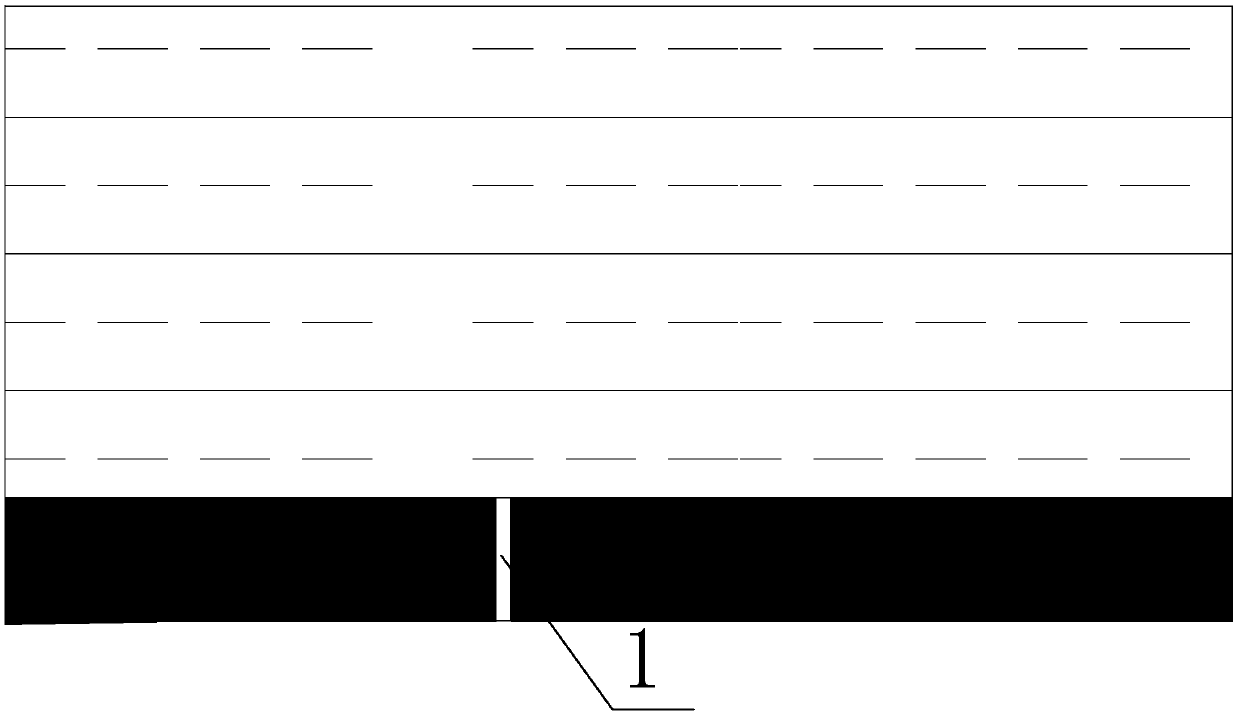

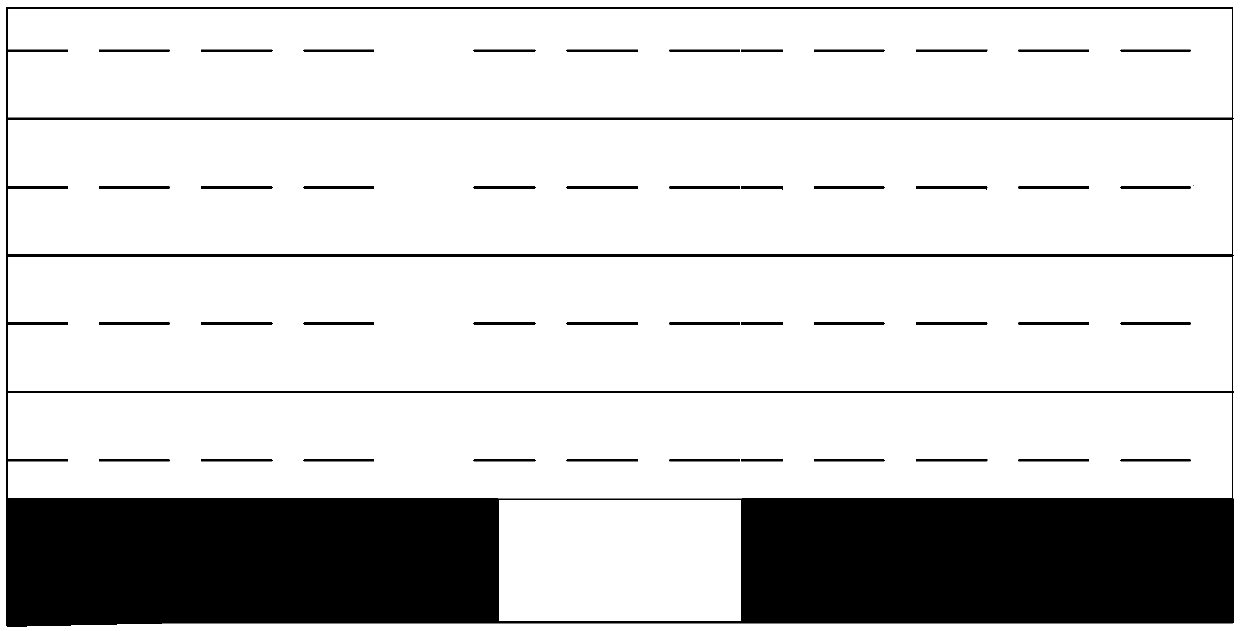

[0043] The present invention provides a strip-like coal mining method for top cutting and filling adjacent goafs. In order to make the purpose, technical scheme and effect of the present invention clearer and clearer, the present invention will be further described in detail below. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

[0044] The invention provides a strip-like coal mining method for top cutting and filling adjacent goafs, which comprises the following steps:

[0045] Step 1, the size of strip mining is smaller than the first caving step distance L of the immediate top 0 , to keep the roof from collapsing, the small strip coal pillars are mined first, and the large strip coal pillars are left, and the thickness of the roof directly after mining the small strip coal is:

[0046]

[0047] where: m z — immediate roof thickness;

[0048] h—mining height of sma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com