Installation process used for deeply-buried earth pressure cells

An earth pressure cell and installation process technology, which is applied in basic structure engineering, basic structure testing, construction, etc., can solve problems such as easily cut lines, cable breakage, pressure cell overturning, etc., to expand applicability and prevent measurement data. Errors, reducing the effect of the cable being cut

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

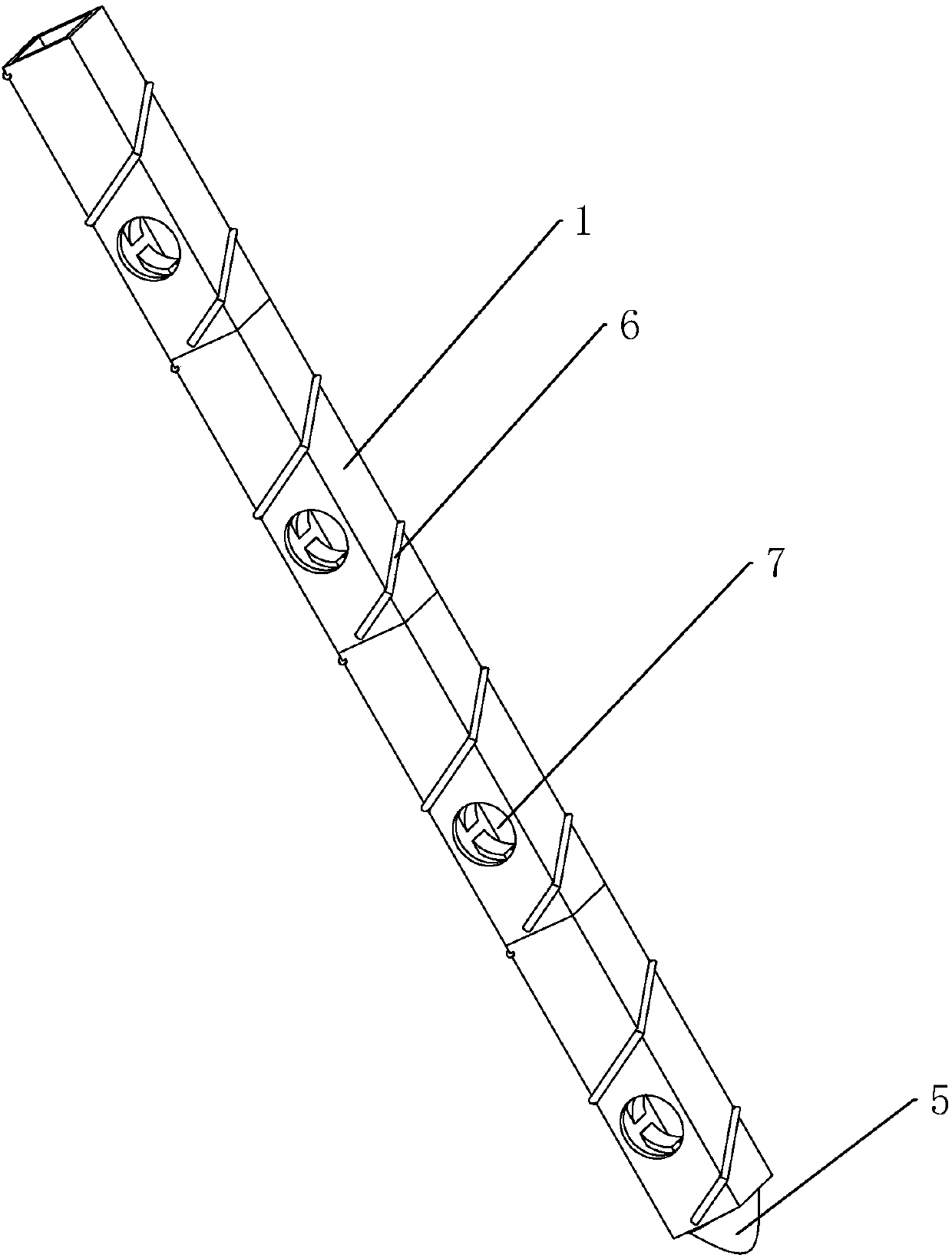

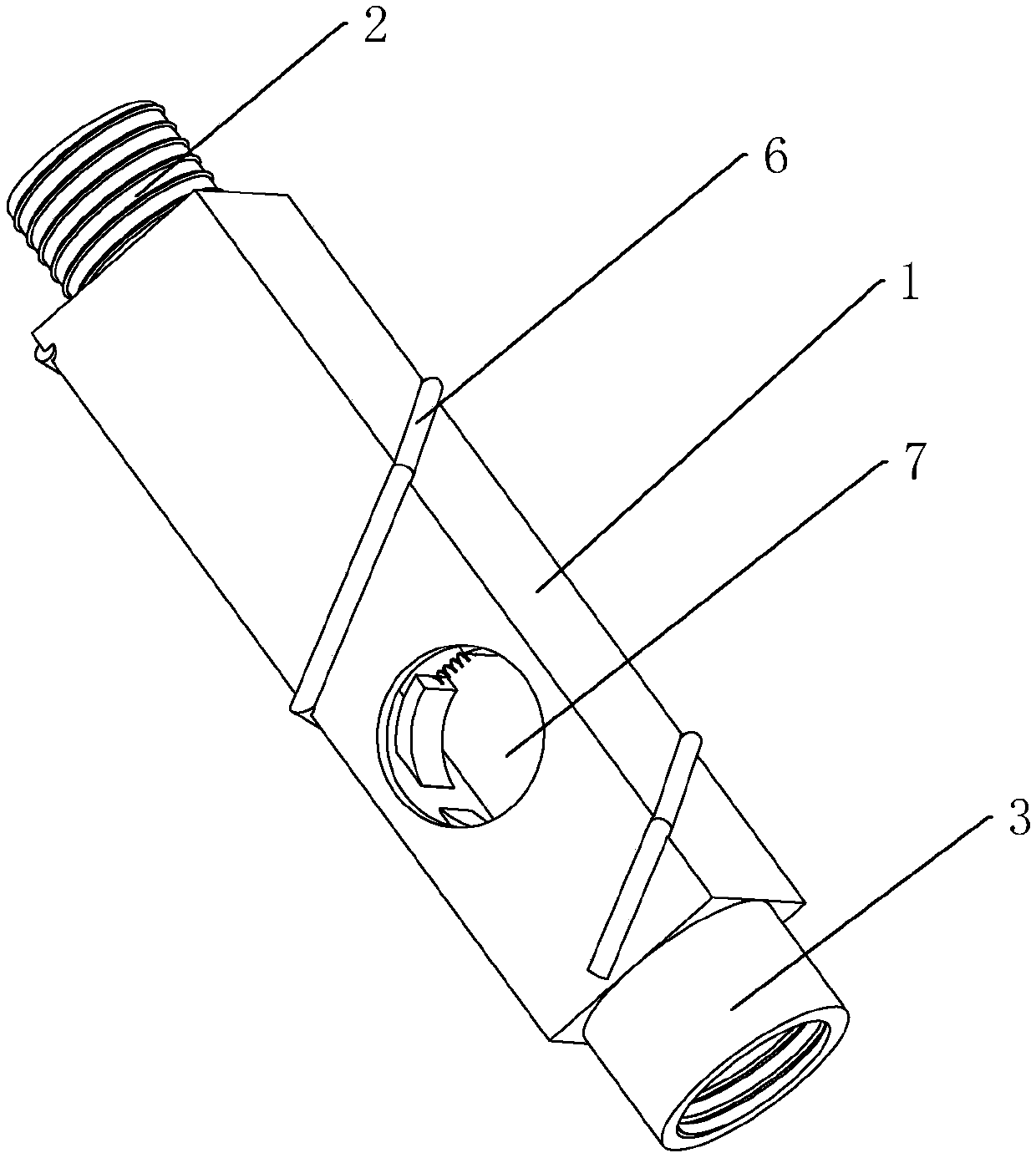

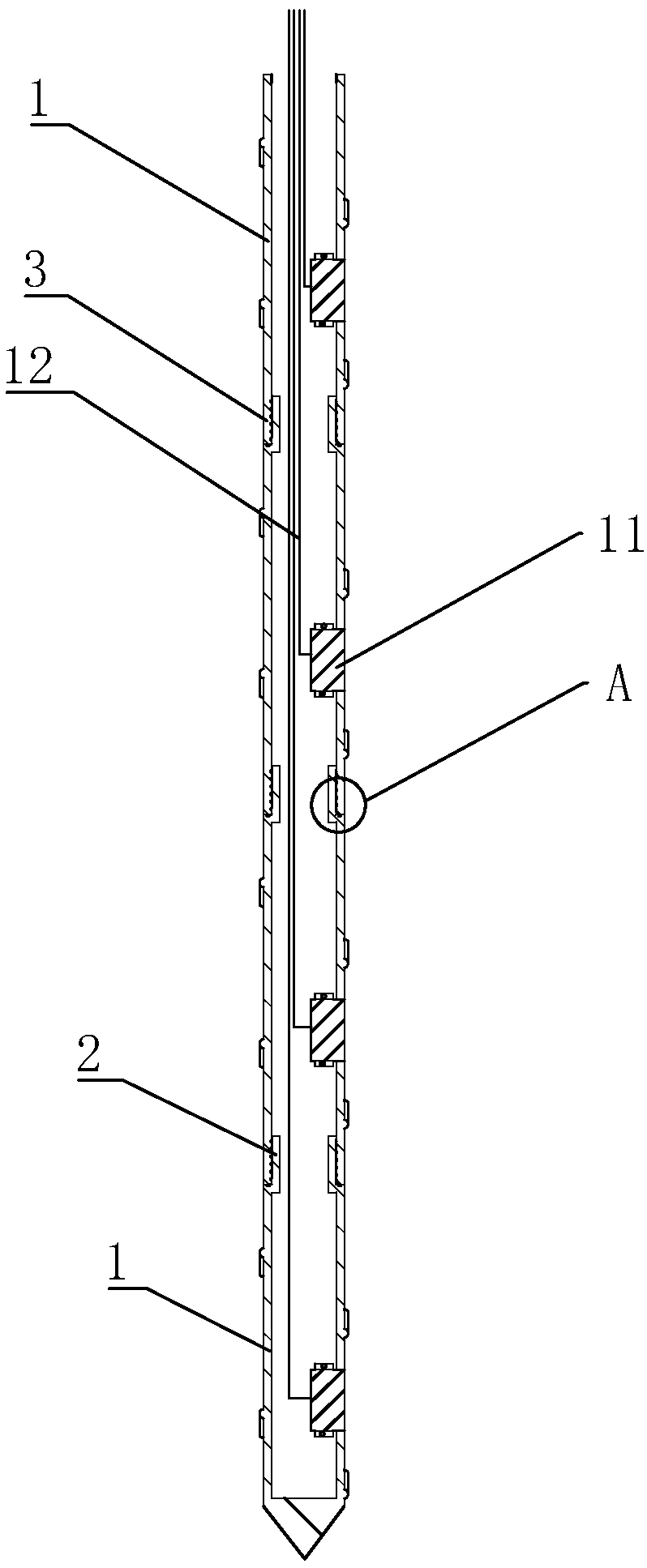

[0046] Such as figure 1 As shown, a bushing assembly for installation of a deep-buried earth pressure cell, the bushing assembly includes several bushings 1, the bushings 1 are square pipes and the bushings 1 are made of PVC. Such as figure 2 As shown, a first connecting piece 2 and a second connecting piece 3 are respectively fixedly arranged at both ends of the sleeve 1 . Such as image 3 As shown, the lowermost casing 1 is only provided with the first connecting piece 2 , and the uppermost casing 1 is only provided with the second connecting piece 3 . Such as figure 2 As shown, the outer wall of the first connector 2 is provided with external threads, and the inner wall of the second connector 3 is provided with internal threads. The first connecting part 2 of the bushing 1 can be screwed to the second connecting part 3 of another bushing 1 . Such as image 3 As shown, when two bushings 1 need to be connected, it is only necessary to screw the first connecting part ...

Embodiment 2

[0052] An installation process for a deep-buried earth pressure cell is characterized in that: the casing 1 in the first embodiment is used, and the steps are as follows,

[0053] S1. Embed and install the earth pressure cell 11 into the installation hole 7, so that the earth pressure cell 11 is fixedly installed on the casing 1, and the axial direction of the earth pressure cell 11 is perpendicular to the axial direction of the casing 1; at the same time, the first clamping plate 8 and The second clamping plate 9 presses against the earth pressure box 11 synchronously under the action of the pressing spring 10, so that the earth pressure box 11 is installed in the casing 1 more stably;

[0054] S2. Arrange all the bushings 1, and then pass the cable 12 on the earth pressure box 11 through all the bushings 1, so that the upper end of the cable 12 passes through the uppermost bushing 1, and then put all the bushings 1 The sections are fixedly installed together; such as image...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com