Antibacterial real silk dyeing fabric and dyeing process thereof

A silk fabric and process technology, applied in the field of textile printing and dyeing, can solve problems such as rare reports of antibacterial properties, and achieve the effect of good color fastness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

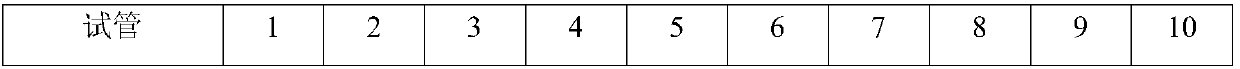

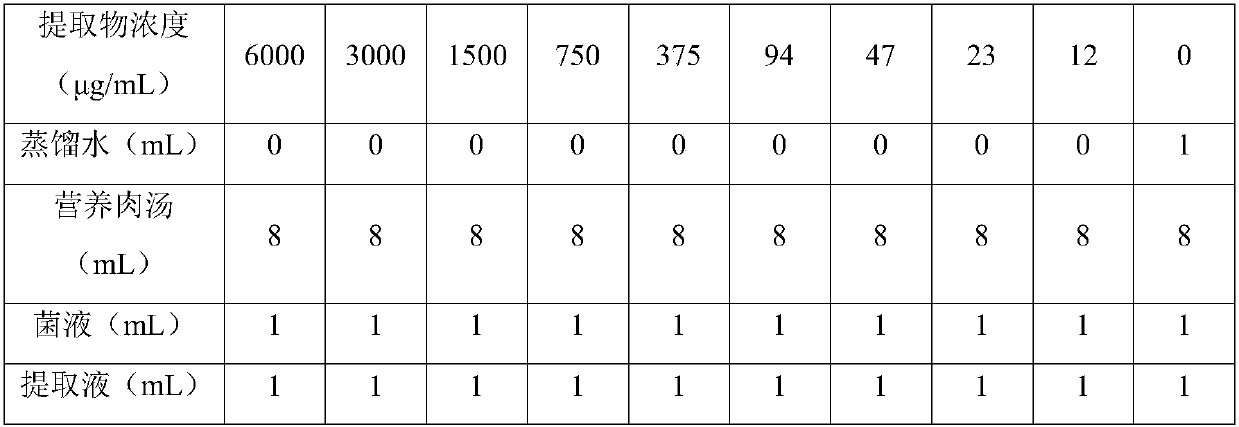

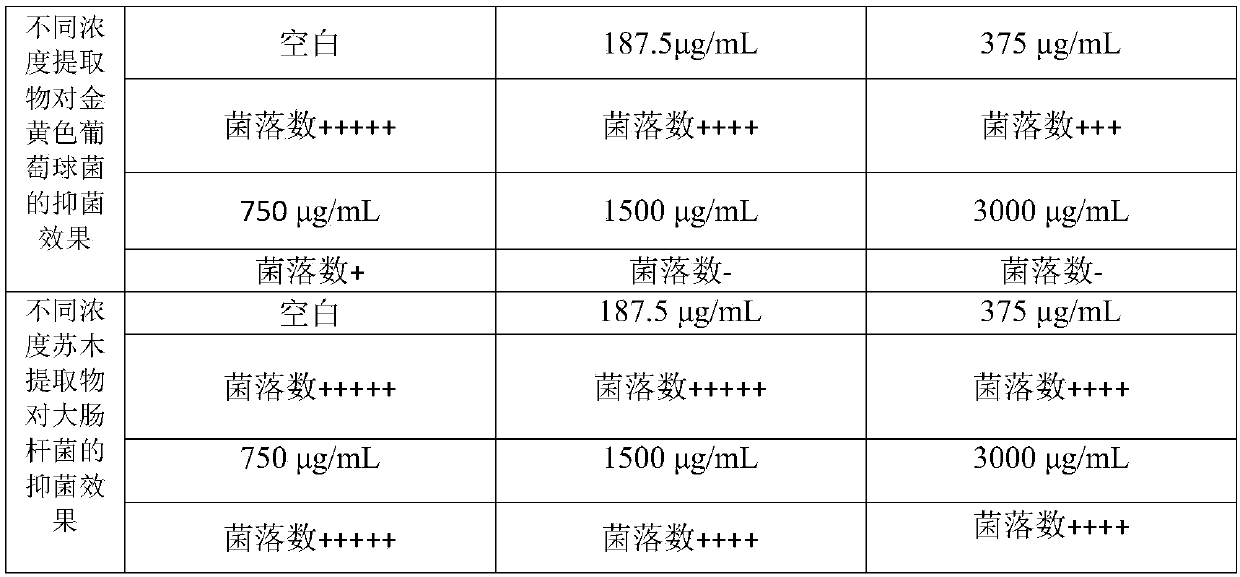

[0019] Take 100g of evenly crushed hematoxylin wood chips, bath ratio 1:40, soak for 2h, decoct for 1.5h, filter, and use the same method to repeatedly extract the obtained filter residue once, filter, combine the filtrate, and concentrate to 1% of the volume of the filtrate. / 3, placed in an oven, and dried at 65°C to obtain hematoxylin extract powder. When preparing hematoxylin dye solution, measure the powder, dilute to a certain concentration with distilled water, and sterilize at 115°C for 30 minutes.

Embodiment 2

[0021] Take 100g of evenly crushed hematoxylin wood chips, bath ratio 1:45, soak for 2h, decoct for 2h, filter, and use the same method to repeatedly extract the obtained filter residue once, filter, combine the filtrate, and concentrate to 1 / 2 of the volume of the filtrate. 3. Put it in an oven and dry it at 65°C to obtain the extract powder of hematoxylin. When preparing hematoxylin staining solution, measure the powder, dilute to a certain concentration with distilled water, and sterilize at 115°C for 40 minutes.

Embodiment 3

[0023] Take 100g of evenly crushed hematoxylin wood chips, bath ratio 1:50, soak for 2h, decoct for 2h, filter, and use the same method to repeatedly extract the obtained filter residue once, filter, combine the filtrate, and concentrate to 1 / 2 of the volume of the filtrate. 3. Put it in an oven and dry it at 65°C to obtain the extract powder of hematoxylin. When preparing hematoxylin staining solution, measure the powder, dilute to a certain concentration with distilled water, and sterilize at 115°C for 50 minutes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com