Laser marking machine and method of adjusting distance between scanning head and marking object and automatic focusing method of marking machine

A laser marking machine and laser marking technology, applied in the field of laser marking, can solve the problems of reducing marking accuracy and speed, and achieve the effect of increasing marking speed and ensuring accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

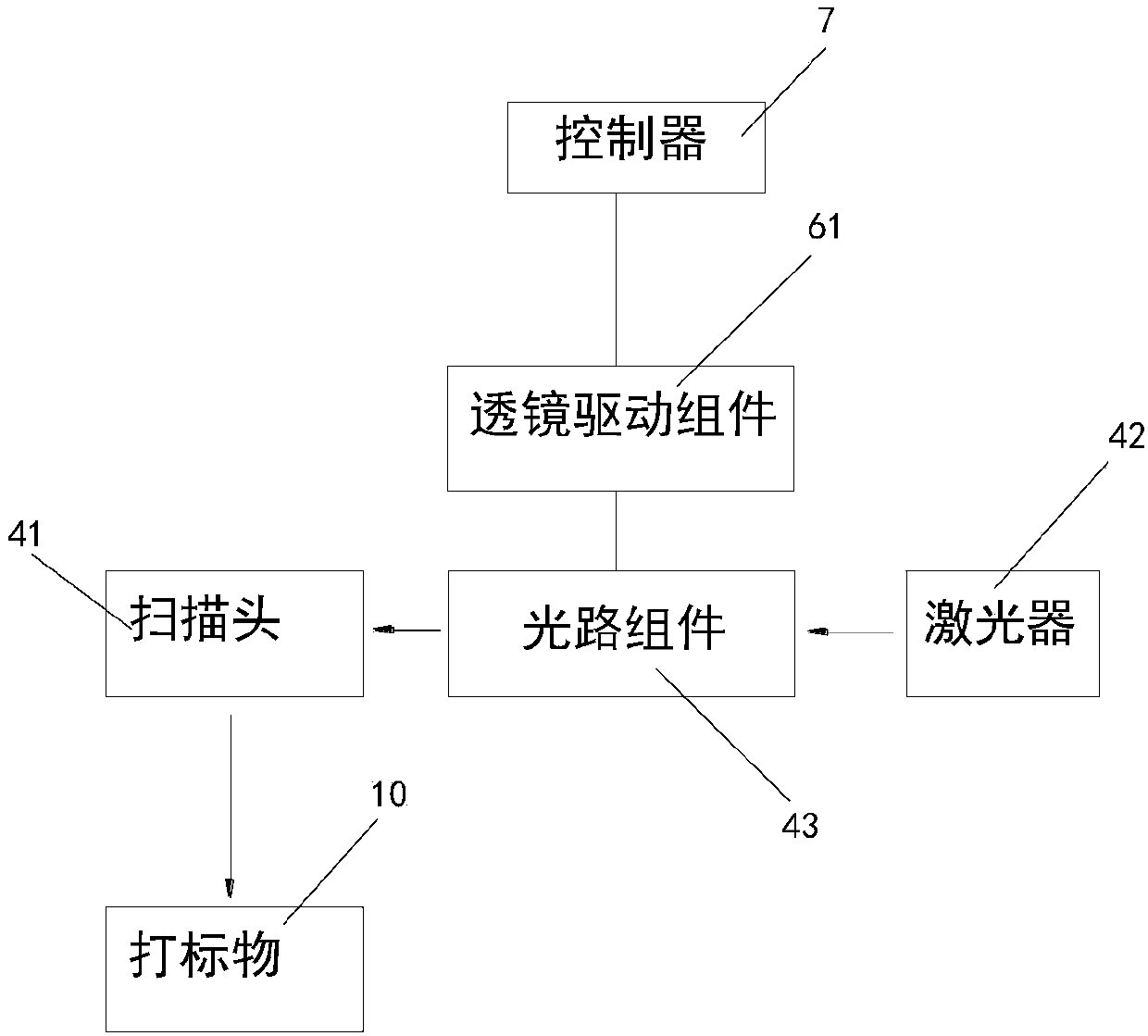

[0024] A laser marking machine, such as figure 1 and figure 2 As shown, a base 1 is included, and a frame 2 is arranged on the base 1. A vertically extending guide rail is provided on the frame 2. A pallet 3 is arranged on the guide rail, and the pallet 3 can slide along the guide rail. A laser marking assembly 4 is arranged on the pallet 3 , the laser marking assembly 4 is used to generate marking laser, and the marking laser is emitted from the scanning head 41 .

[0025] The scanning head includes an X mirror and a Y mirror installed in sequence. The X mirror is installed on the rotation output shaft of the X motor, and the Y mirror is installed on the rotation output shaft of the Y motor. The direction of the rotation axis of the X motor is the same as that of the Y motor. The directions of the rotation axes are perpendicular to each other, and the marking laser is shot onto the X mirror and the Y mirror in turn. After the X mirror and the Y mirror change direction, the ...

Embodiment 2

[0033] The difference between this embodiment and embodiment 1 mainly lies in the second drive assembly. Specifically:

[0034] Laser marking machine, including a base and a marking machine table for placing marking objects on the base, the marking machine table can move up and down, the frame above the marking machine table, the support table set on the frame, the support table A laser marking component is set on the table, and the laser marking component includes a laser, an optical path assembly and a scanning head installed in sequence. The optical path assembly includes several concave lenses and / or convex lenses, located between the laser and the scanning head, for adjusting the beam of the incident laser The focal length, the marking laser exits from the laser, passes through the optical path assembly, and enters the scanning head. The scanning head includes several reflective lenses, which are used to change the direction of the marking laser, so that the marking laser...

Embodiment 3

[0038] This implementation is improved on the basis of Embodiment 1 or 2, and this embodiment illustrates a solution for a laser marking machine for three-dimensional marking objects.

[0039] like Image 6 As shown, when specifically marking the marking object 10, the laser marking machine can also be connected to an external control terminal. A virtual model of the marking object 10 is established in the control terminal, and the marking pattern is pasted on the surface of the virtual model.

[0040] Because the virtual model of the marking object 10 is stored in the control terminal, and various parameters of the virtual model are also stored, as long as the distance from any point on the model to the distance measuring component 5 is known, the distance from any other point on the virtual model to the distance measuring component 5 can be known. The distance of component 5. Therefore, in this embodiment, a feature point needs to be preset on the surface of the marking ob...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com