Slitting circular cutter

A round knife and blade body technology, which is applied to the accessories of tool holders, tools for lathes, turning equipment, etc., can solve the problems of high price of slitting round knives, easy wear and durability of the blade, and late start of production technology. The effect of preventing the tearing of the cutting section material, reducing the production cost and reducing the difficulty of heat treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

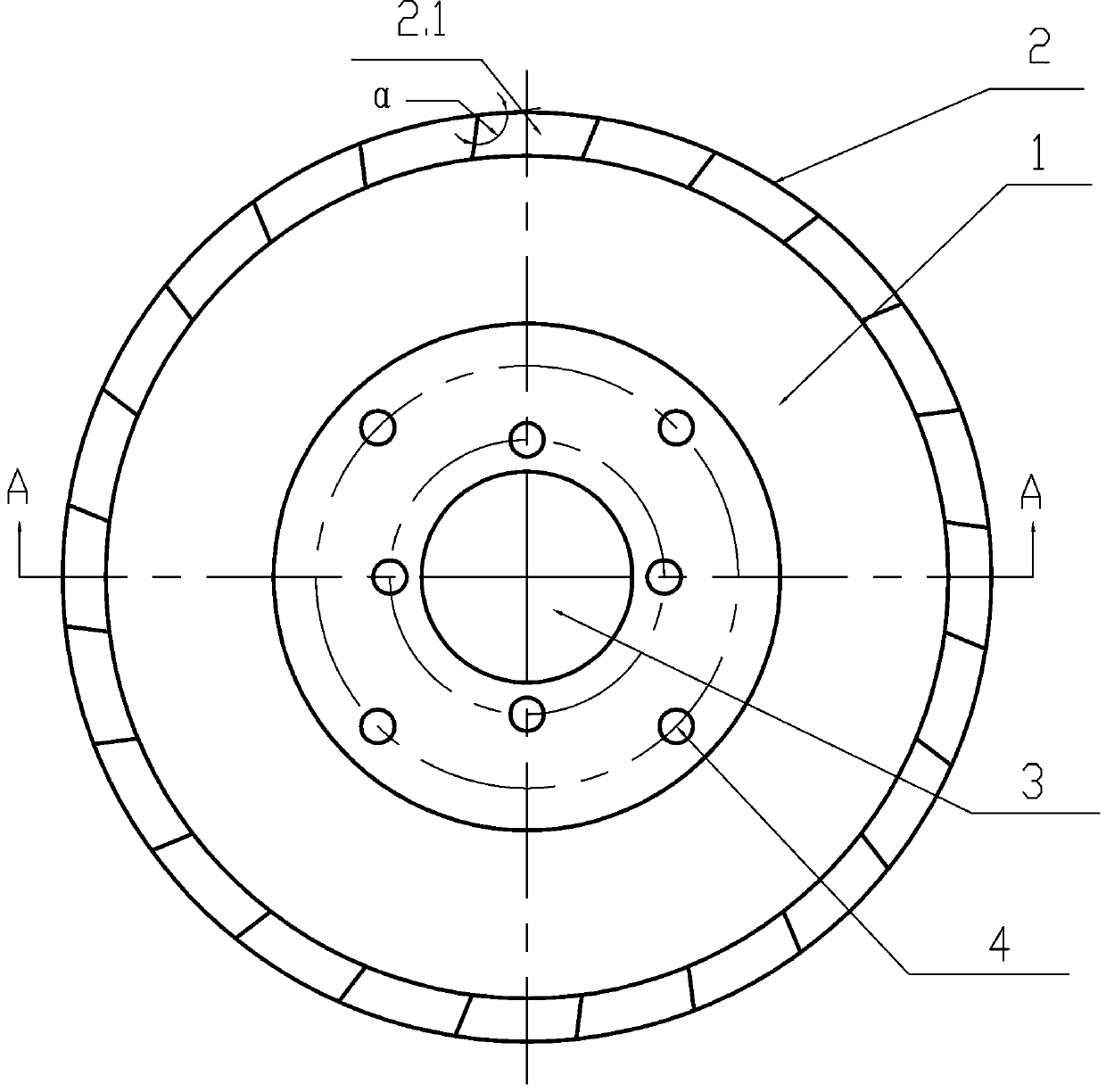

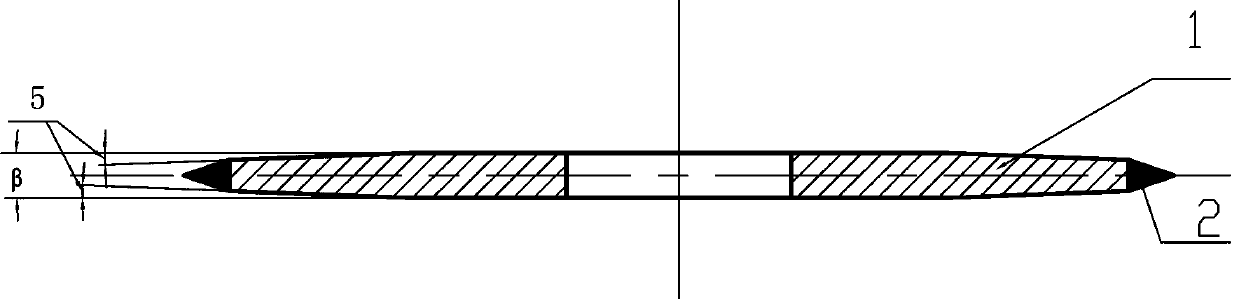

[0017] The structure of the present invention is as figure 1 with figure 2 As shown, the slitting round blade includes a blade body 1 and a cutter head 2; a center hole 3 is provided at the center of the blade body 1, and several transmission holes 4 are arranged near the outer ring of the center hole 3. It is made by heat treatment, quenching and tempering and mechanical processing to meet certain cutting rigidity requirements; the cutter head 2 is composed of a plurality of segments 2.1 made of hard alloy or cermet, and the segments 2.1 are evenly distributed on the cutter by welding or other connection methods. 1 on the outer circumference of the body, and then made by sharpening.

[0018] After the node 2.1 on the knife body 1 of the present invention is worn due to use, the node made of cemented carbide or cermet can be welded again to achieve the purpose of repeated use, and the entry angle α of the cutting node is set as Obtuse angle, preferably 110°~150°, when the k...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com