Automatic meat ball processing machine

A processing machine and meatball technology, applied in meat processing equipment, processed meat, slaughtering, etc., can solve the problems of manpower consumption and low production efficiency, and achieve the effects of improving production efficiency, simple structure, and consistent size and shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

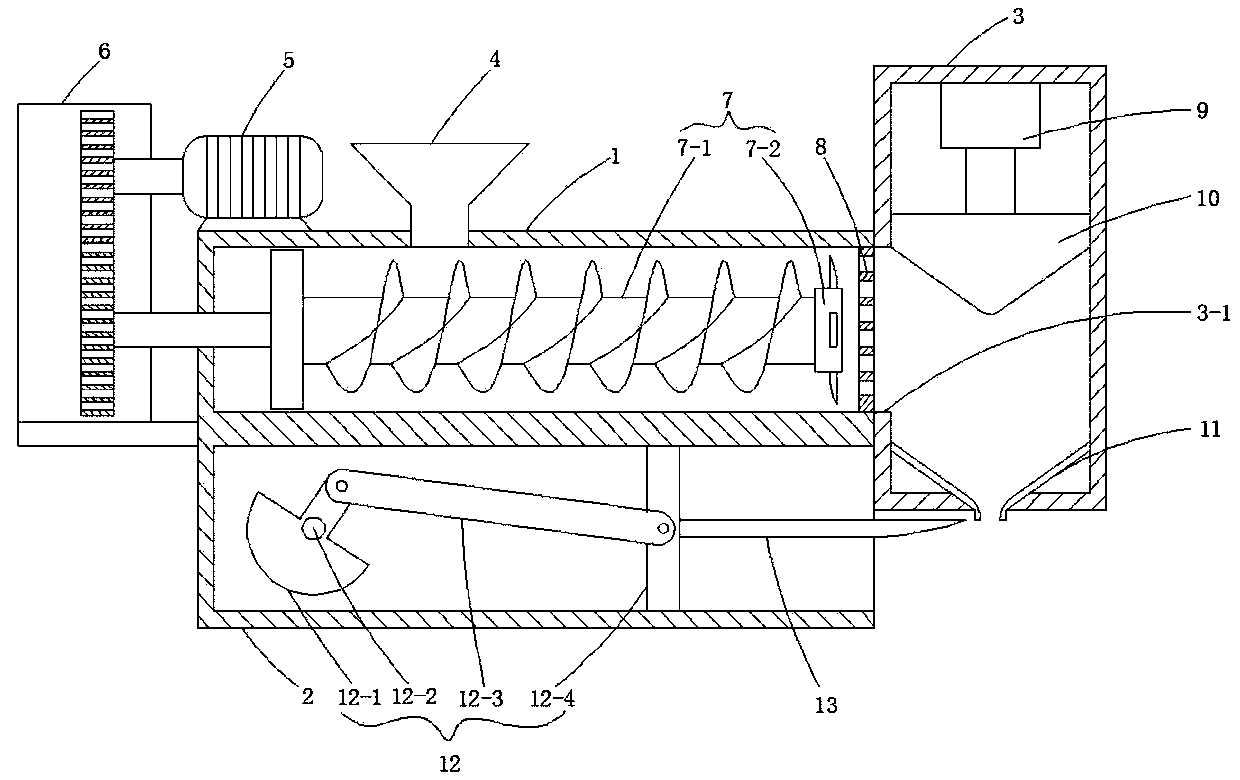

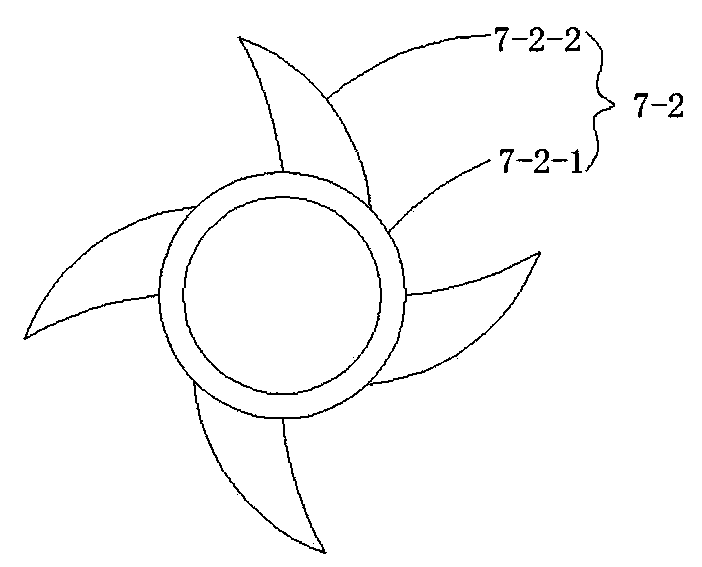

[0018] like Figures 1 to 2 As shown, the present embodiment provides an automatic meatball processing machine, comprising a meat grinding cylinder 1, a cutting box 2 positioned below the meat grinding cylinder 1, an extrusion cylinder 3 installed on the sides of the meat grinding cylinder 1 and the cutting box 2, and extruding A through hole 3-1 is provided at the connecting portion of the pressing cylinder 3 and the meat grinding cylinder 1, a feeding funnel 4 is arranged above the meat grinding cylinder 1, and a meat grinding mechanism 7 is arranged in the meat grinding cylinder 1, and the meat grinding mechanism 7 includes an auger 7-1 and the extruding knife group 7-2 that is arranged on the end of the auger 7-1, the extruding knife group 7-2 includes the blade installation shaft 7-2-1 fixed on the auger 7-1, the blade installation shaft The 7-2-1 is provided with some evenly distributed blades 7-2-2, and the extruding knife group 7-2 is provided with a meat extruding pla...

Embodiment 2

[0021] like Figures 1 to 2 As shown, this embodiment is further optimized on the basis of Embodiment 1. Specifically, the meat grinding mechanism 7 is connected with a gear reduction box 6 arranged outside the meat grinding cylinder 1, and the gear reduction box 6 is connected with a Drive motor 5.

[0022] The lower end of the extrusion hammer 10 is set in a shape compatible with the funnel-shaped discharge nozzle 11, and the extrusion hammer 10 is in the shape of a top as a whole.

[0023] The rotating shaft 12-2 is connected with a motor.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com