Filling placing device for making dumplings

A stuffing device and accommodating cavity technology, which is applied in the field of stuffing devices for making dumplings, can solve the problems of easy stuffing, low production efficiency, and high production cost, and achieve the effects of consistent size and shape, high work efficiency, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

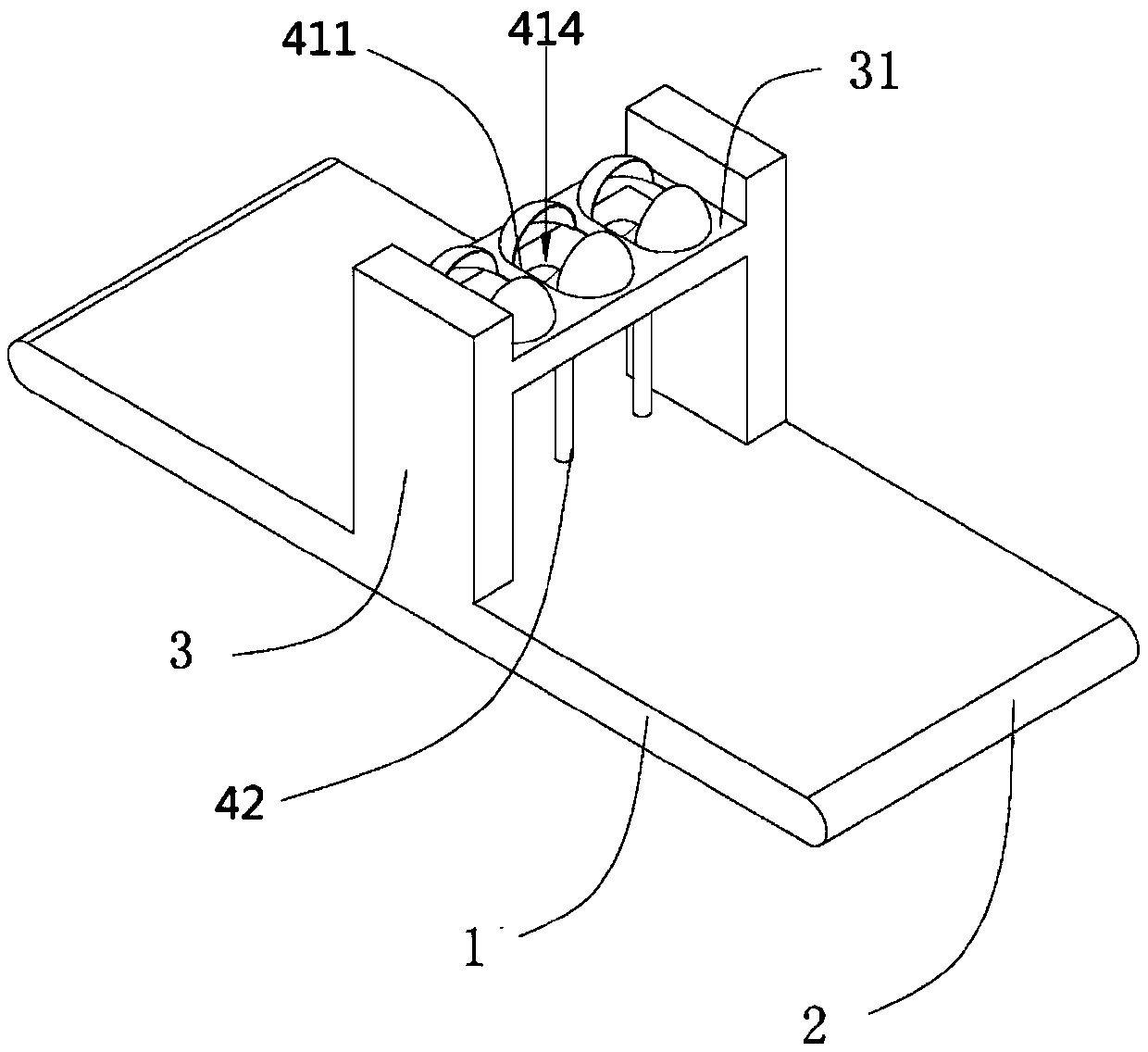

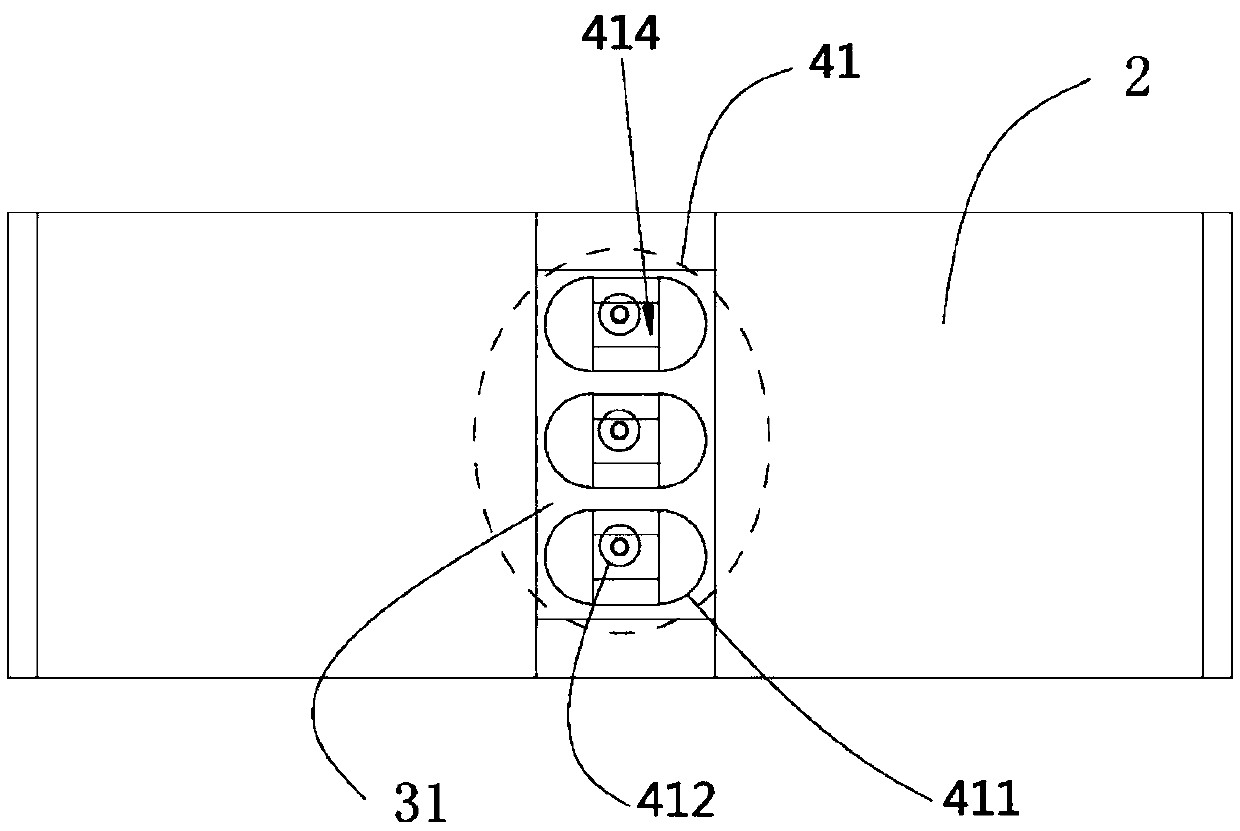

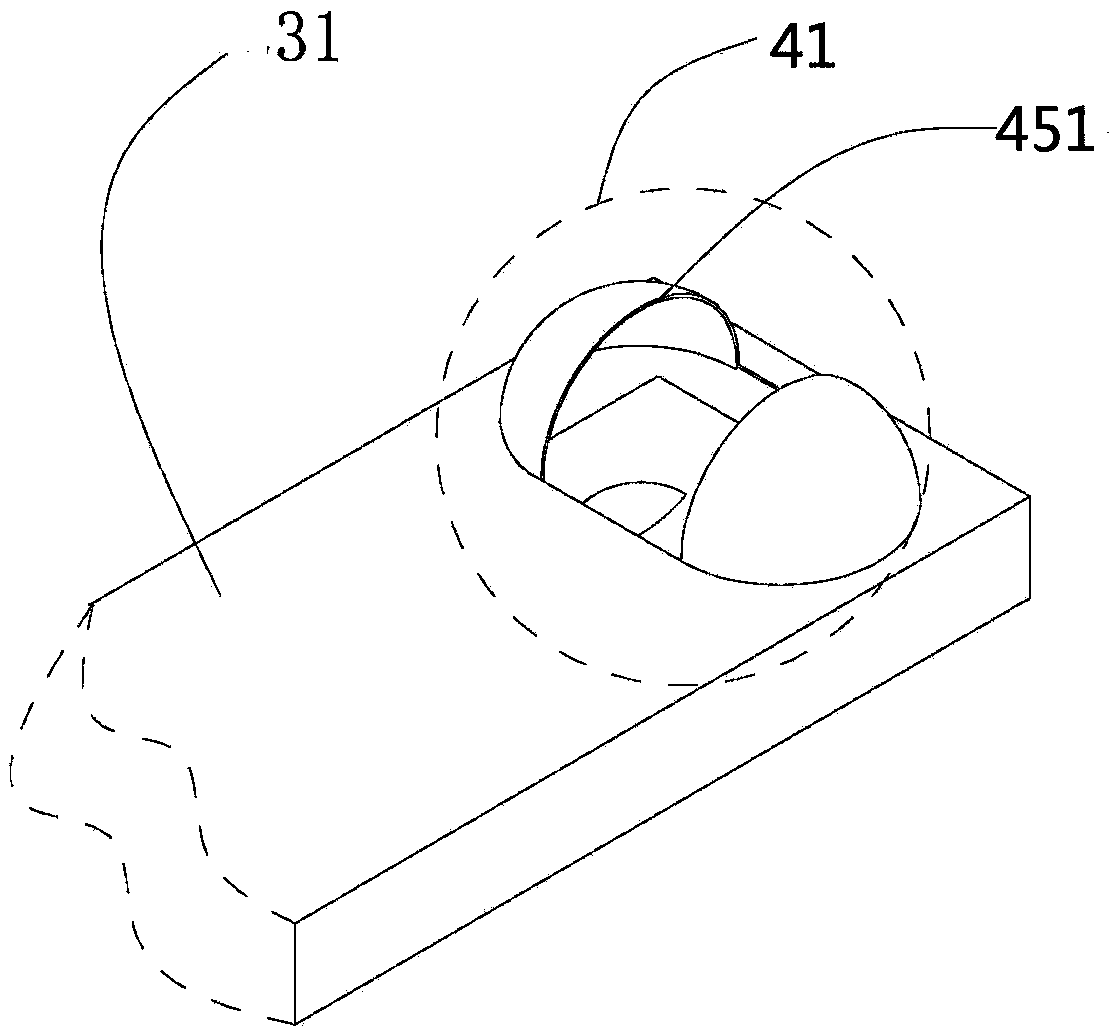

[0029] Such as figure 1 , figure 2 as well as image 3 As shown, a stuffing device for making dumplings includes a device body 1, a transmission belt 2, a support frame 3 and a stuffing device 4 arranged on the support frame 3, and the number of the support frame 3 is 2, so The support frames 3 are respectively on both sides of the device body 1, the transmission belt 2 is arranged on the upper surface of the device body 1, the stuffing device 4 includes a stuffing feeder 41 and a conduit 42, and the stuffing feeder The number of 41 is three, the support frame 3 is provided with a seat body 31, the stuffing machine 41 is arranged on the seat body 31, the conduit 42 passes through the seat body 31 and communicates with the stuffing machine 41, and the stuffing machine 41 includes a body 411 and a spray gun 412. The part of the body 411 in contact with the plate surface of the seat 31 is oval. The body 411 has an accommodating cavity 414, and the accommodating cavity 414 is o...

Embodiment 2

[0032] A stuffing device for making dumplings, comprising a device body 1, a transmission belt 2, a support frame 3 and a stuffing device 4 arranged on the support frame 3, the number of the support frame 3 is 2, and the support frame 3 respectively on both sides of the device body 1, the transmission belt 2 is arranged on the upper surface of the device body 1, the stuffing device 4 includes a stuffing feeder 41 and a conduit 42, and the support frame 3 is provided with Base 31, the stuffing machine 41 is arranged on the base 31, the conduit 42 passes through the base 31 and communicates with the stuffing machine 41, the stuffing machine 41 includes a body 411 and a spray gun 412, the body 411 and the seat The part of the body 31 in contact with the plate surface is oval, and the body 411 has an accommodating cavity 414, and the accommodating cavity 414 is opened in the middle of the part of the stuffing feeder 41 located on the seat body 31, and the body 411 also includes Ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com