Circuit support for an electronic circuit, and method for manufacturing a circuit support of said type

A circuit carrier, electronic circuit technology, applied in printed circuit manufacturing, printed circuit dielectrics, printed circuits, etc., can solve problems such as adverse cost effects, material loss, limited heat dissipation, etc., achieve high power levels, less material transitions, The effect of less structural space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

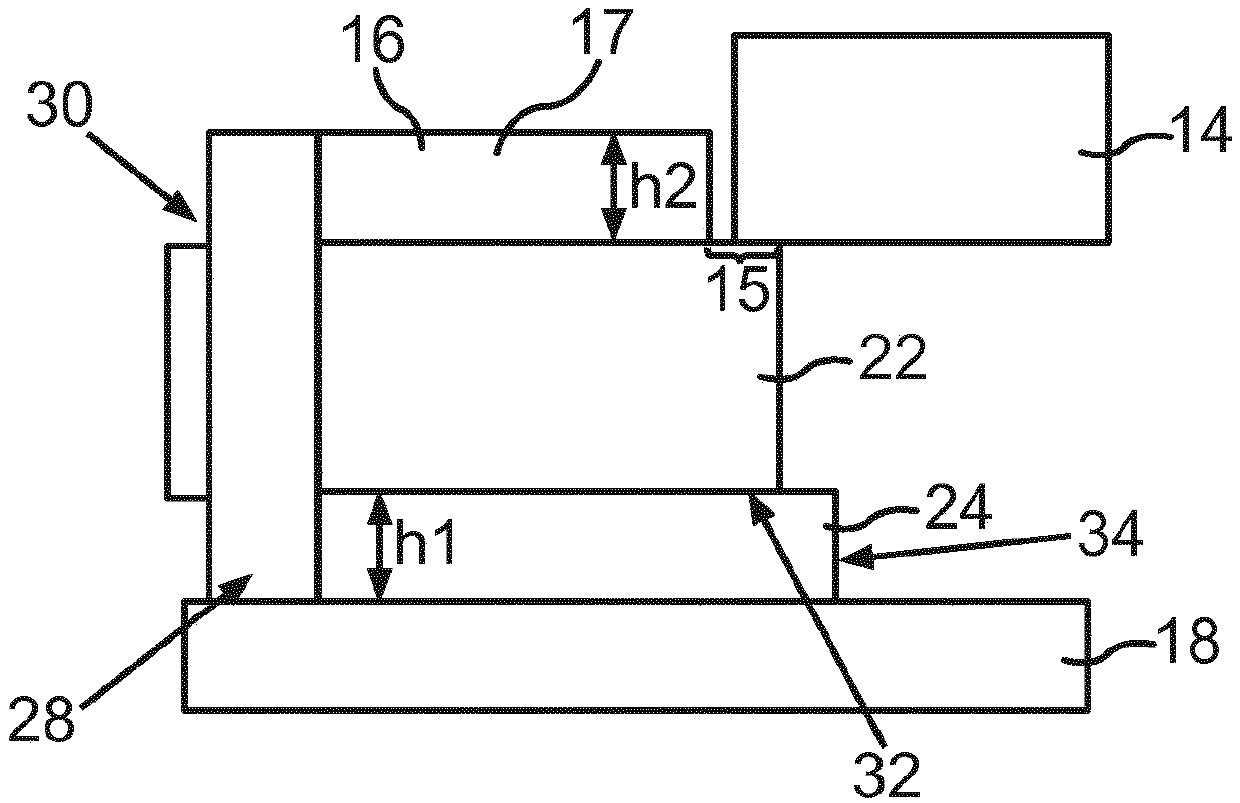

[0044] image 3 A schematic diagram of a first exemplary embodiment of a circuit carrier according to the invention is shown. The circuit carrier has conductor tracks 22 which are designed in particular as lead frames. Perforations and / or gaps 30 are provided in the conductor tracks 22 , which are also injection-molded when the conductor tracks are injection-molded with the first insulating material 17 for producing the insulating base body 16 In this case, in particular, the projection 28 is also formed on the side of the conductor track 22 that is to be coupled to the cooling body 18 . The projection 28 can also extend below the conductor track 22 in order to ensure a better form fit and / or force fit. During the injection molding with the first insulating material 17 , the region 15 provided for mounting the electronic component 14 is thus freed, as well as the region 34 on the underside 32 of the conductor track 22 . This is achieved by designing the injection mold accor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com