Droplet evaporation test device

A test device, droplet evaporation technology, applied in the direction of using combustion for chemical analysis, etc., can solve the problems that the droplet evaporation cannot be measured, the high-pressure evaporation environment of the engine combustion chamber cannot be provided, and there is no pressure chamber, so as to solve the problem of suspended liquid droplets The effect of evaporation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but the protection scope of the present invention is not limited thereto.

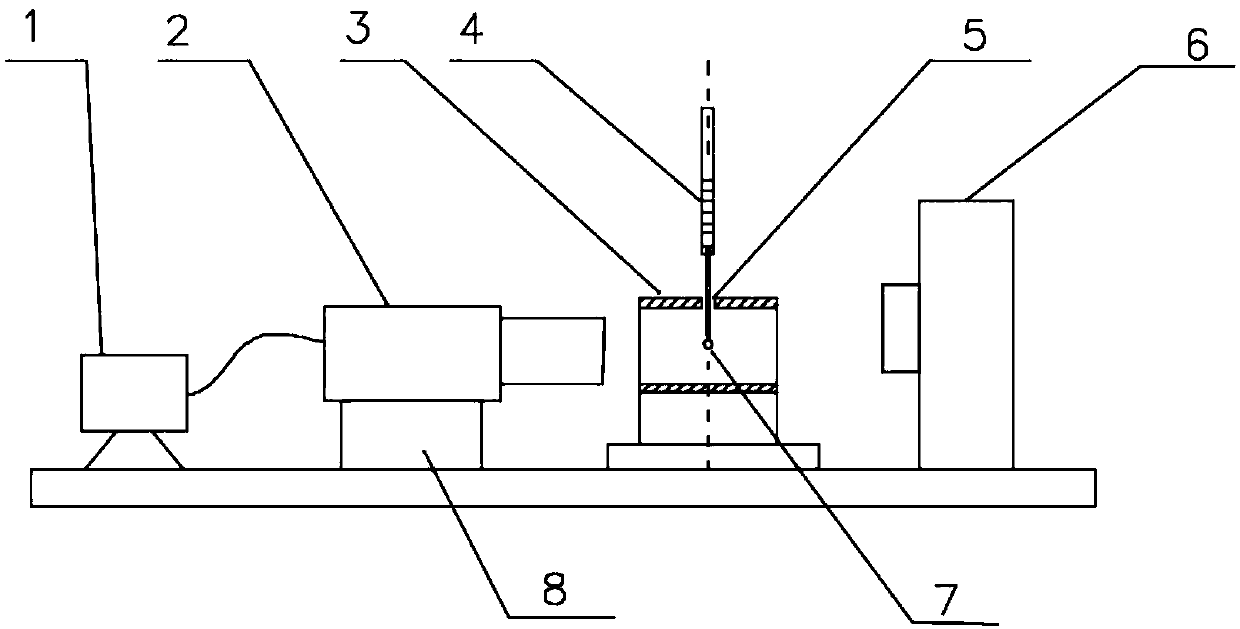

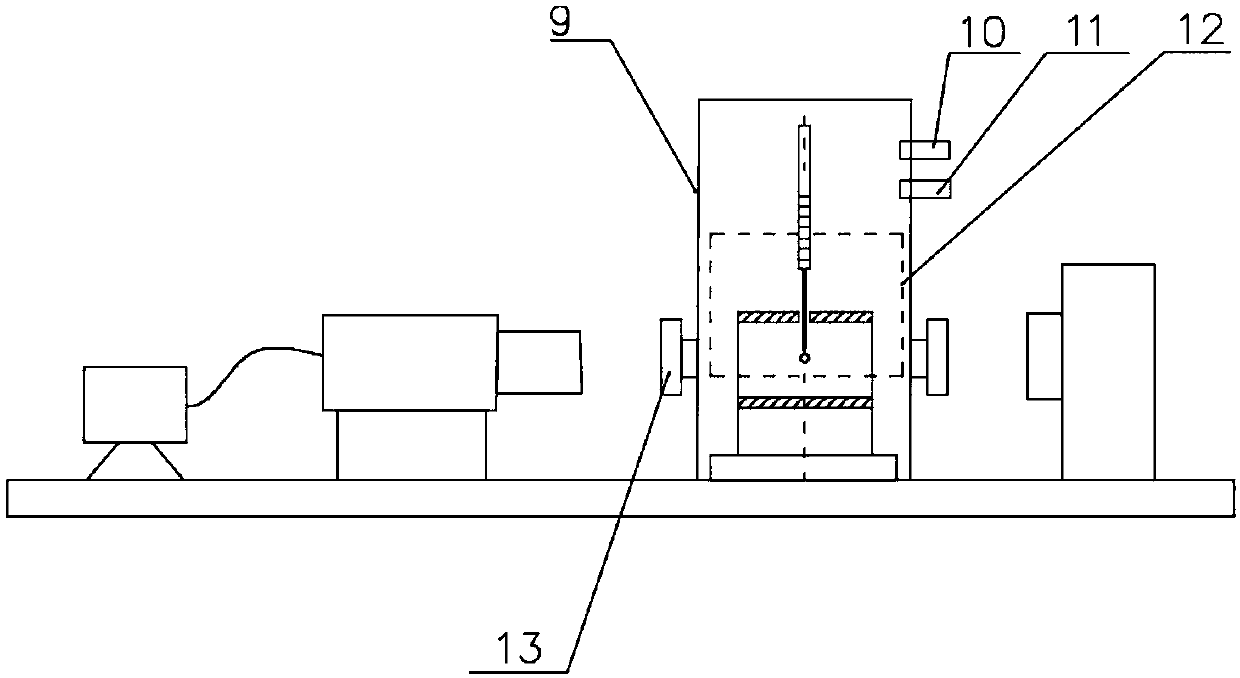

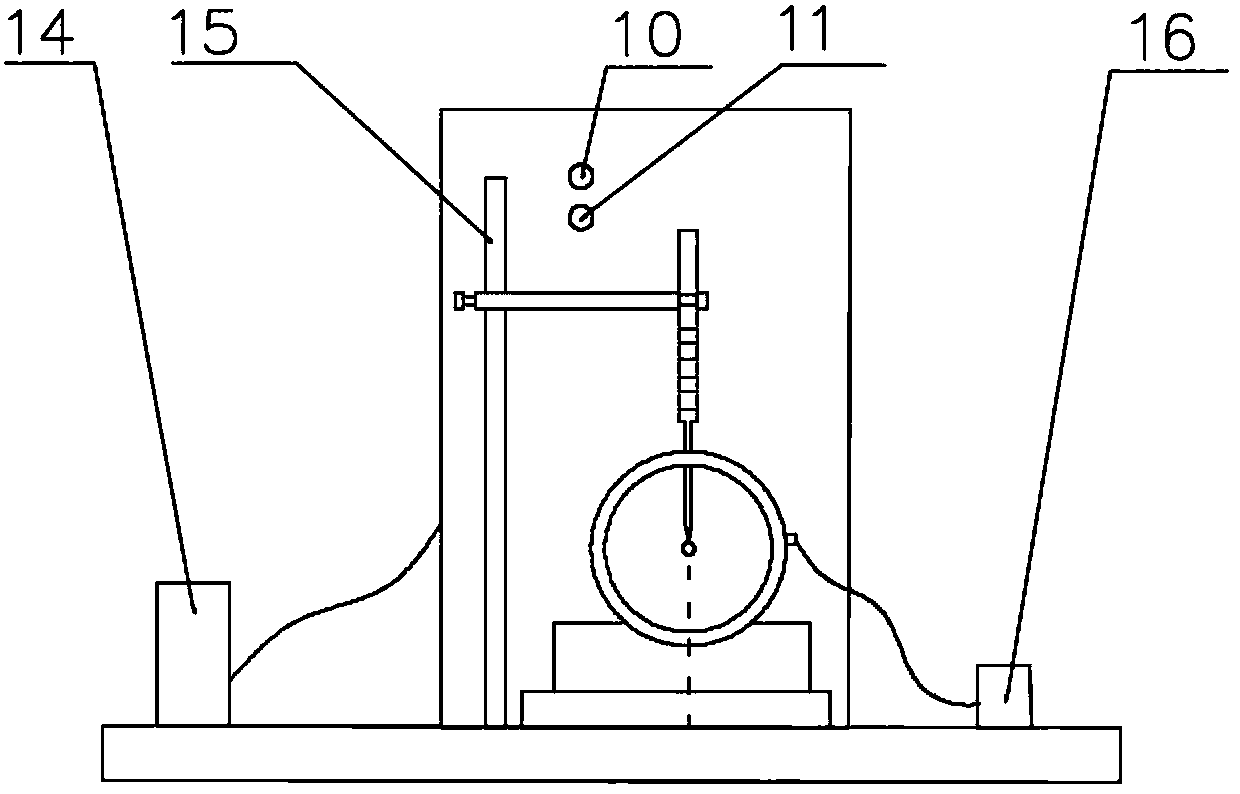

[0023] like figure 1 As shown, a droplet evaporation test device under a pressure-free state includes a shooting system, a heating device and a micro-sampler 4; the heating device includes a heating ring 3, and the top of the heating ring 3 is provided with a through hole 5, The micro-sampler 4 extends into the heating ring 3 through the through hole 5, and does not contact the inner wall of the heating ring 3; the micro-sampling device 4 is suspended on the iron frame platform 15; There is a temperature regulator 16, which is used to adjust the temperature inside the heating ring 3; the photographing system includes a high-speed camera 2 and a diffuse light source 6, and the high-speed camera 2 is positioned at one side of the heating ring 3, and is used for photographin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com