Waterproof anti-shock lock master control box

A main control box, anti-shock technology, applied in the field of mechanical equipment components, can solve problems such as short circuit of internal circuit, unsealed lock cylinder mechanism, and possible disengagement from the hook at one end, so as to achieve uniform structural tight pressure and eliminate safety. Hidden danger, avoid the effect of poor waterproof

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

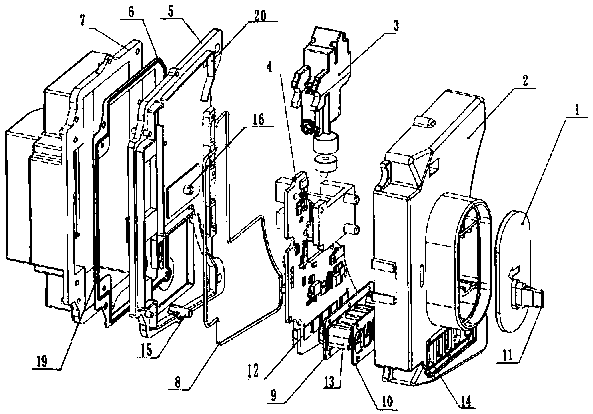

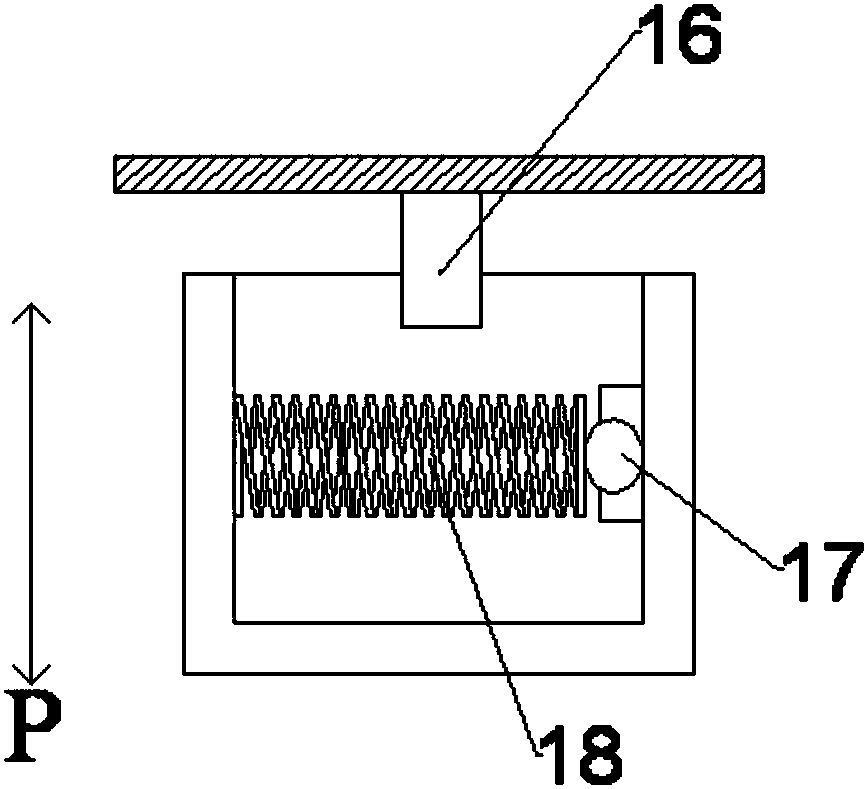

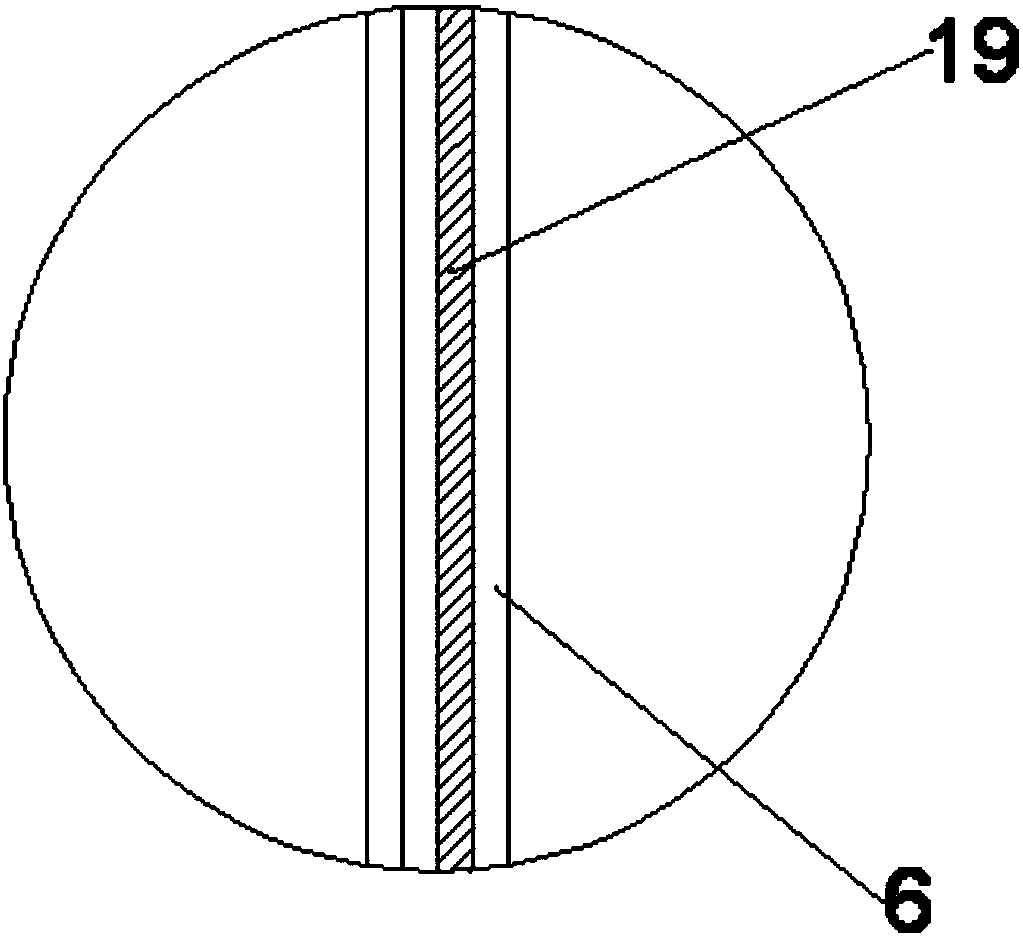

[0023] Such as figure 1 The main control box of a kind of waterproof and shockproof lock shown, it comprises front circuit board warehouse 2, decelerating motor 3, main control circuit board 4, middle partition board 5 and rear battery compartment 7 successively from front to back, and the front circuit An antenna cover 1 is provided on the outside of the board warehouse 2, a waterproof sealing groove is provided on the inside of the antenna cover 1, and a light guide column 11 is provided on the outside, and the light guide column 11 is closely connected with the antenna cover 1; the main control circuit board 4. Below is the keypad 12, the keypad 12 includes a number of keys 13, the keypad 13 is surrounded by a key sealing edge 9, the front of the keypad 13 is provided with a pressing plate 10, on the keypad 12, the keypad 13 is installed There is a first waterproof groove 14; the main control circuit board support column 15 is provided below the key board 12, and the anti-f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com