Humidification anti-static device

A technology for removing static electricity and cotton box, applied in the direction of static electricity, deburring device, electrical components, etc., can solve the problems of prolonging production cycle, reducing humidity, increasing production cost, etc., to improve the quality of sliver and prevent the effect of humidity reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

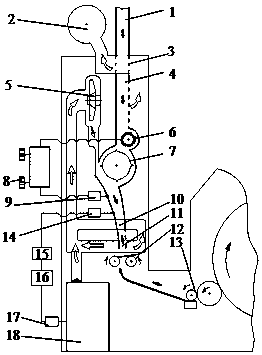

[0009] Such as figure 1 As shown, a humidification and static removal device includes a cotton delivery pipe 1, an upper cotton storage box 4, a lower cotton storage box 10, an air outlet 3 of the upper cotton storage box, an air outlet 11 of the lower cotton storage box, and a dust exhaust air duct 2. , fan 5, pressure sensor 9 and pressure parameter adjustment device 8, cotton feeding roller 6, opening beater 7, humidifier 18 and its PLC controller 16, A / D converter 15, ultrasonic generator 17 and humidity sensor 14 , the fiber in the cotton delivery pipe 1 at the top of the upper storage box 4 is brought into the upper storage box 4 by the air flow, and through the opening process of the cotton feeding roller 6 and the opening beater 7, enters the lower cotton storage box 10, and then successively passes through The further opening of the feeding roller 12 and the carding machine feeding roller 13 is finally fed into the carding machine for carding, and the suction effect o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com