Preparation method of microalgae biodiesel with high caloric heat

A technology of microalgae biology and high calorific value, which is applied in the fields of bioengineering and clean energy preparation, which can solve the problems of low oil production efficiency and low calorific value, so as to improve oil production efficiency, promote the accumulation of oil in algae cells, and improve oil production efficiency. quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

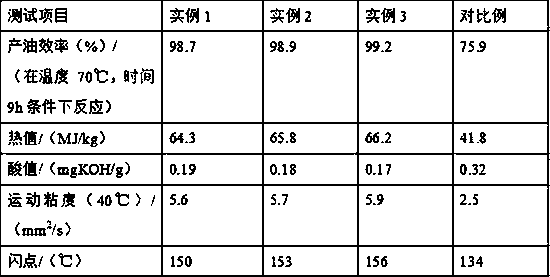

Examples

example 1

[0026]Take 0.5kg of river bottom sludge and put it in a beaker, add 800mL of distilled water into the beaker, seal the mouth of the beaker with a ventilating plug, move it into a water bath, heat up to 90°C, cook for 2 hours, cool naturally to room temperature, and let it stand for 10 minutes. , filtered to remove the lower layer of sediment, to obtain a supernatant, sterilized distilled water was added to the supernatant to a total volume of 900mL, to obtain a soil extract; Inoculate the inoculation density of / mL into the soil extract solution, control the temperature of the culture solution at 26°C, and the intensity of visible light irradiation at 2000Lx, and cultivate for 4 days; add 70mL biogas slurry, 50g shell powder, and 20g Nile Red to the above-mentioned conical flask, And place a beaker filled with potassium permanganate solution with a mass fraction of 65% between the air pump and the Erlenmeyer flask, connect the air pump, beaker, and Erlenmeyer flask with a glass...

example 2

[0028] Take 0.6kg of river bottom sludge and put it in a beaker, add 900mL of distilled water into the beaker, seal the mouth of the beaker with a ventilating plug, move it into a water bath, heat up to 95°C, cook for 2.5h, cool naturally to room temperature, and let it stand for stratification After 13 minutes, remove the lower layer of sediment by filtration to obtain a supernatant, add sterilized distilled water to the supernatant to a total volume of 950mL, and obtain a soil extract; The inoculation density of cells / mL was inoculated into the soil extract solution, the temperature of the culture solution was controlled at 27°C, and the intensity of visible light irradiation was 2100Lx, and cultured for 4.5 days; 75mL of biogas slurry, 55g of shell powder, and 25g of Nile Red were added to the above-mentioned Erlenmeyer flask , and place a beaker filled with potassium permanganate solution with a mass fraction of 65% between the air pump and the Erlenmeyer flask. Air was in...

example 3

[0031] Take 0.7kg of river bottom sludge and put it in a beaker, add 1000mL of distilled water into the beaker, seal the mouth of the beaker with a ventilating plug, move it into a water bath, heat up to 100°C, cook for 3 hours, cool naturally to room temperature, and let it stand for 15 minutes. , filtered to remove the lower sediment, to obtain the supernatant, sterilized distilled water was added to the supernatant to a total volume of 1000mL, to obtain the soil extract; Inoculate the inoculation density of / mL into the soil extract solution, control the temperature of the culture solution at 28°C, and the intensity of visible light irradiation at 2200Lx, and cultivate for 5 days; add 80mL biogas slurry, 60g shell powder, and 30g Nile Red to the above-mentioned conical flask, And place a beaker filled with potassium permanganate solution with a mass fraction of 65% between the air pump and the Erlenmeyer flask, connect the air pump, beaker, and Erlenmeyer flask with a glass ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com