Preparation method of cellulose-based antibacterial material dialdehyde cellulose-lysine

A technology of dialdehyde cellulose and lysine, which is applied in the fields of botanical equipment and methods, chemicals for biological control, biocides, etc., can solve the problems of lysine deficiency, etc. A wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

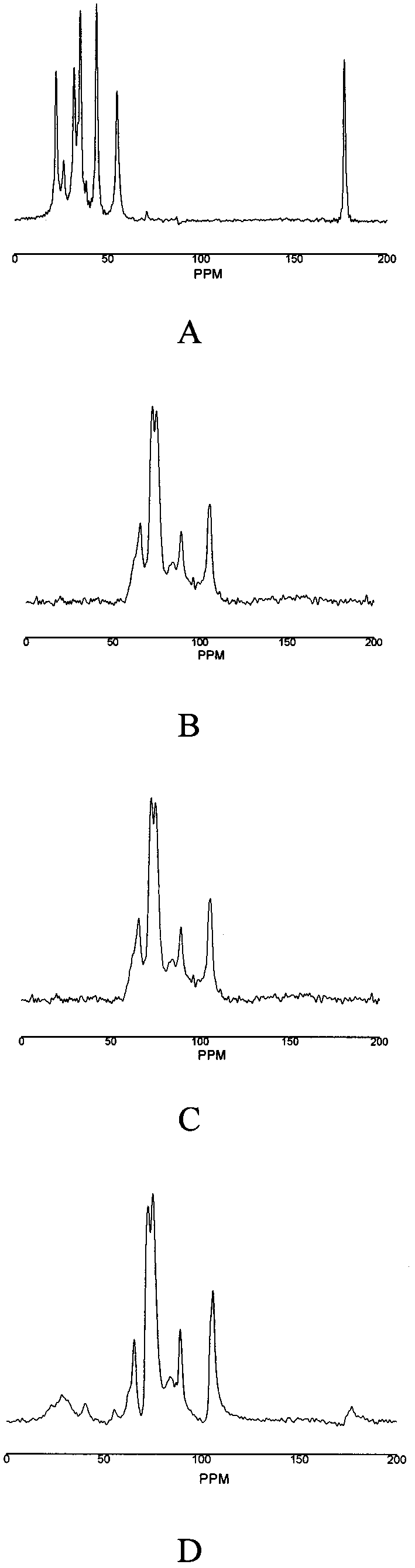

Method used

Image

Examples

Embodiment 1

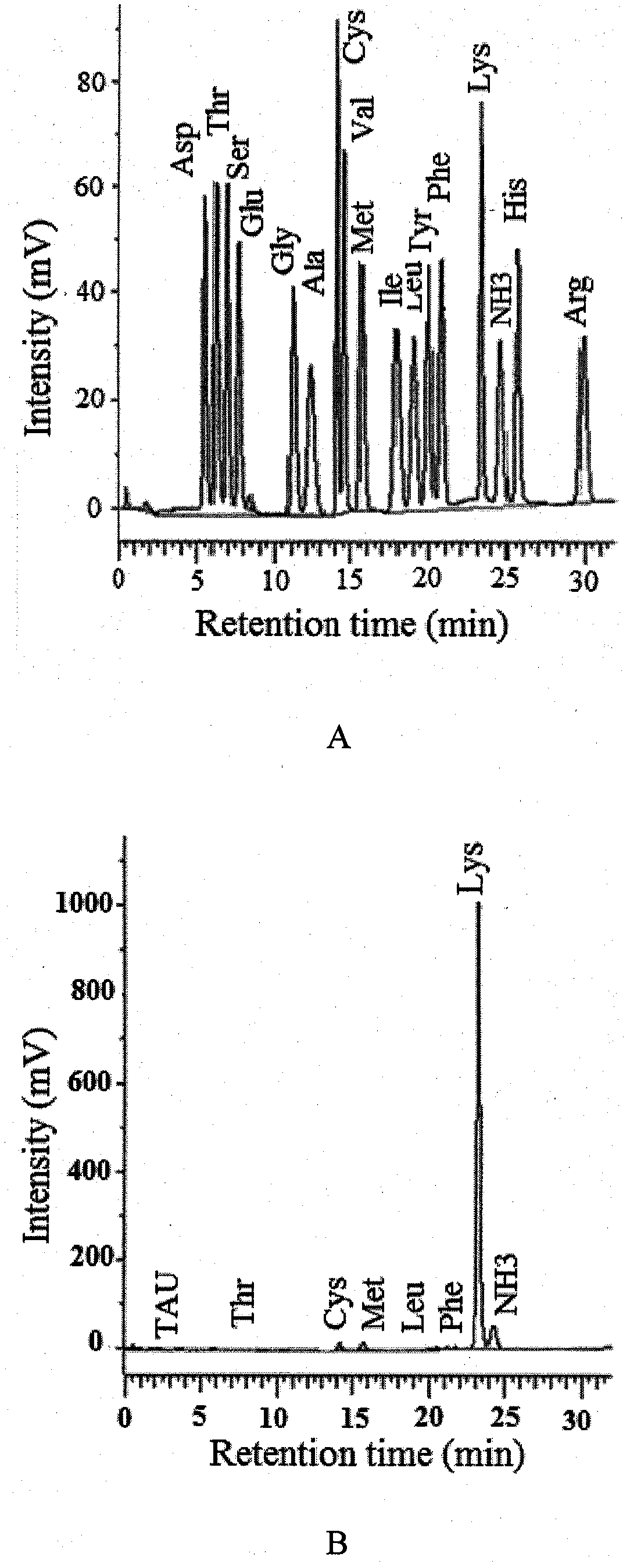

[0038] (1) Dialdehyde cellulose and lysine with a degree of oxidation of 67.7% were weighed according to a molar ratio of 1:1.2, added to 100 times distilled water, adjusted to pH 10 with 10% sodium hydroxide, at 40°C , placed in a water bath constant temperature shaker to react for 8h;

[0039] (2) After the reaction finishes, the centrifugal precipitation is dried;

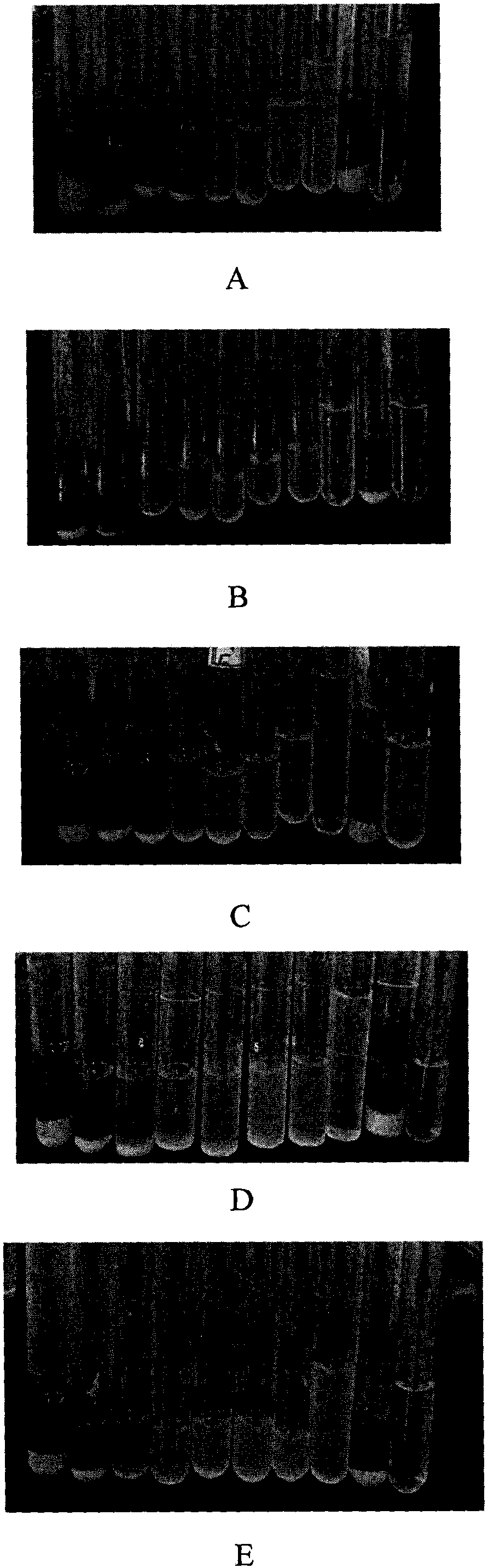

[0040] (3) antibacterial material is carried out antibacterial experiment to sarcinina;

[0041] The MIC of the bacteriostatic material to Sarcina is 7.5mg / mL; the lysine content of the bacteriostatic material is about 11.53g / 100g.

Embodiment 2

[0043] (1) Dialdehyde cellulose and lysine with a degree of oxidation of 67.7% were weighed according to a molar ratio of 1:1.2, added to 100 times distilled water, adjusted to pH 10 with 10% sodium hydroxide, at 40°C , placed in a water bath constant temperature shaker to react for 8h;

[0044] (2) After the reaction finishes, the centrifugal precipitation is dried;

[0045] (3) Antibacterial material is carried out antibacterial experiment to Escherichia coli;

[0046] The MIC of the bacteriostatic material to Escherichia coli is 7.5mg / mL; the lysine content of the bacteriostatic material is about 11.30g / 100g.

Embodiment 3

[0048] (1) Dialdehyde cellulose and lysine with a degree of oxidation of 67.7% were weighed according to a molar ratio of 1:1.2, added to 100 times distilled water, adjusted to pH 10 with 10% sodium hydroxide, at 40°C , placed in a water bath constant temperature shaker to react for 8h;

[0049] (2) After the reaction finishes, the centrifugal precipitation is dried;

[0050] (3) Antibacterial material is carried out antibacterial test to Staphylococcus aureus;

[0051] The MIC of the bacteriostatic material to Staphylococcus aureus is 30mg / mL; the lysine content of the bacteriostatic material is about 10.53g / 100g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| oxidation state | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com