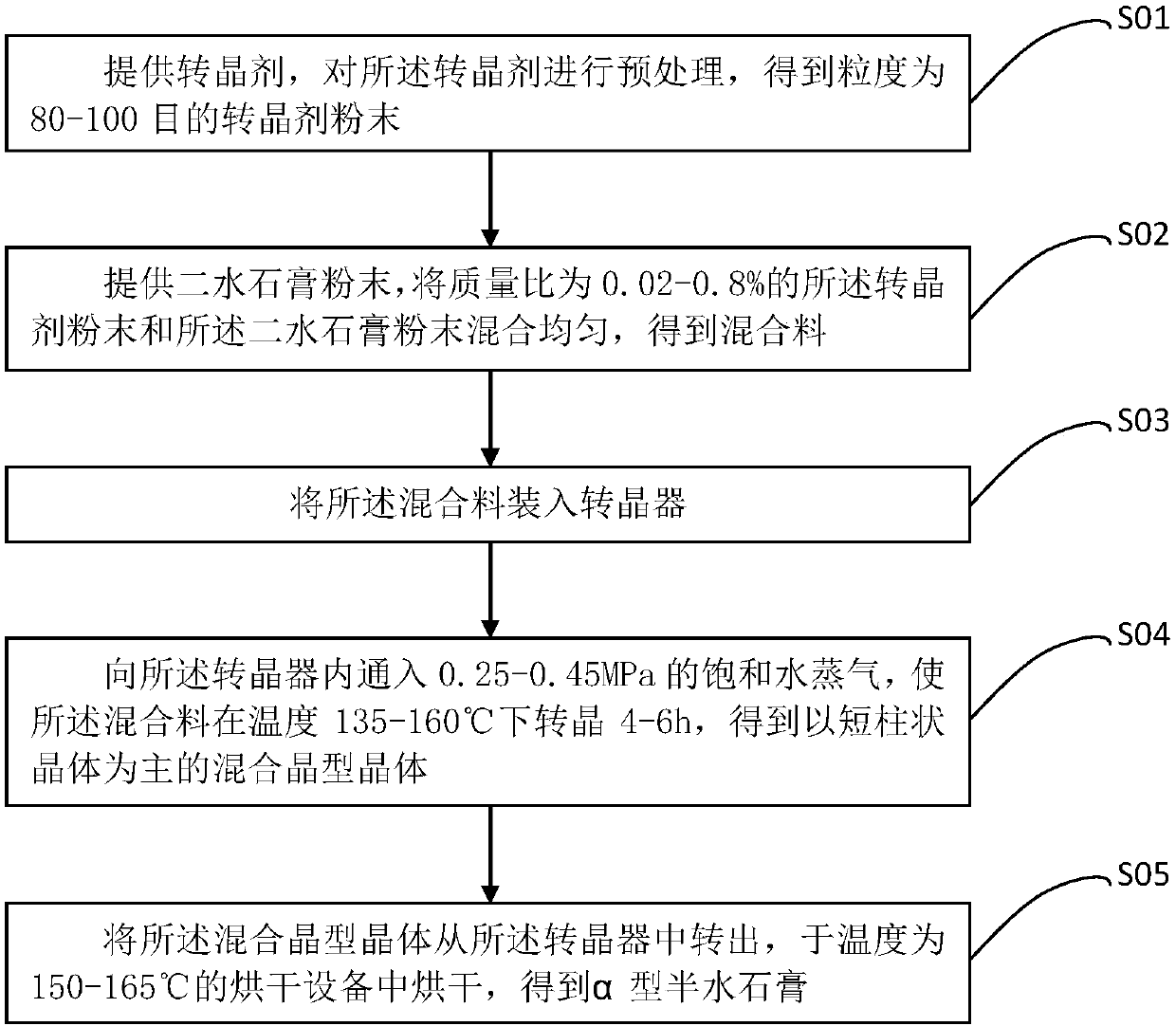

Method for high-efficiency production of alpha type hemihydrated gypsum

A technology of hemihydrate gypsum and dihydrate gypsum, which is applied in the field of high-efficiency production of α-type hemihydrate gypsum, can solve the problems of low production efficiency, achieve the effects of improving processing capacity, shortening production cycle, and fewer process steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

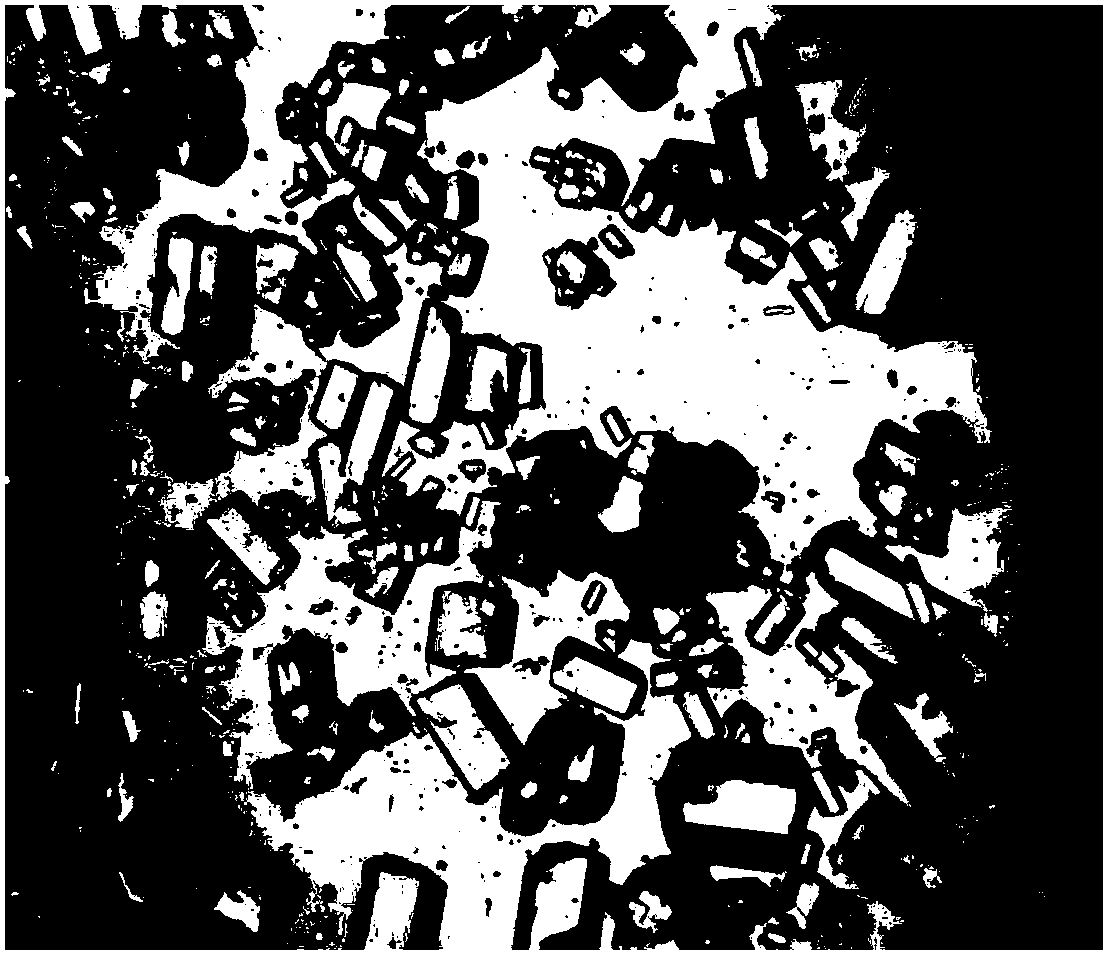

[0048] Aluminum sulfate and citric acid are provided as crystal-transforming agents, the aluminum sulfate and citric acid powder are ground to 100 mesh, and the 100-mesh aluminum sulfate powder and citric acid powder are mixed evenly in a ratio of 1:0.15 by mass ratio to obtain a transcrystalline Crystal agent powder; provide natural dihydrate gypsum powder with a water content of 2% and a particle size range of 0.03-5mm; put the crystal modifier powder and natural dihydrate gypsum powder with a mass of 1.15% of the natural dihydrate gypsum powder into the coulter Mix in the mixer for 5-10min until uniform to obtain the mixture; put the mixture into the crystal converter, the loose volume of the mixture in the crystal converter is 80% of the volume of the crystal converter; Pass 0.35MPa saturated water vapor into the device, and after the temperature in the crystal converter reaches 150°C, heat and hold the pressure for 6 hours to obtain a mixed crystal with short columnar crys...

Embodiment 2

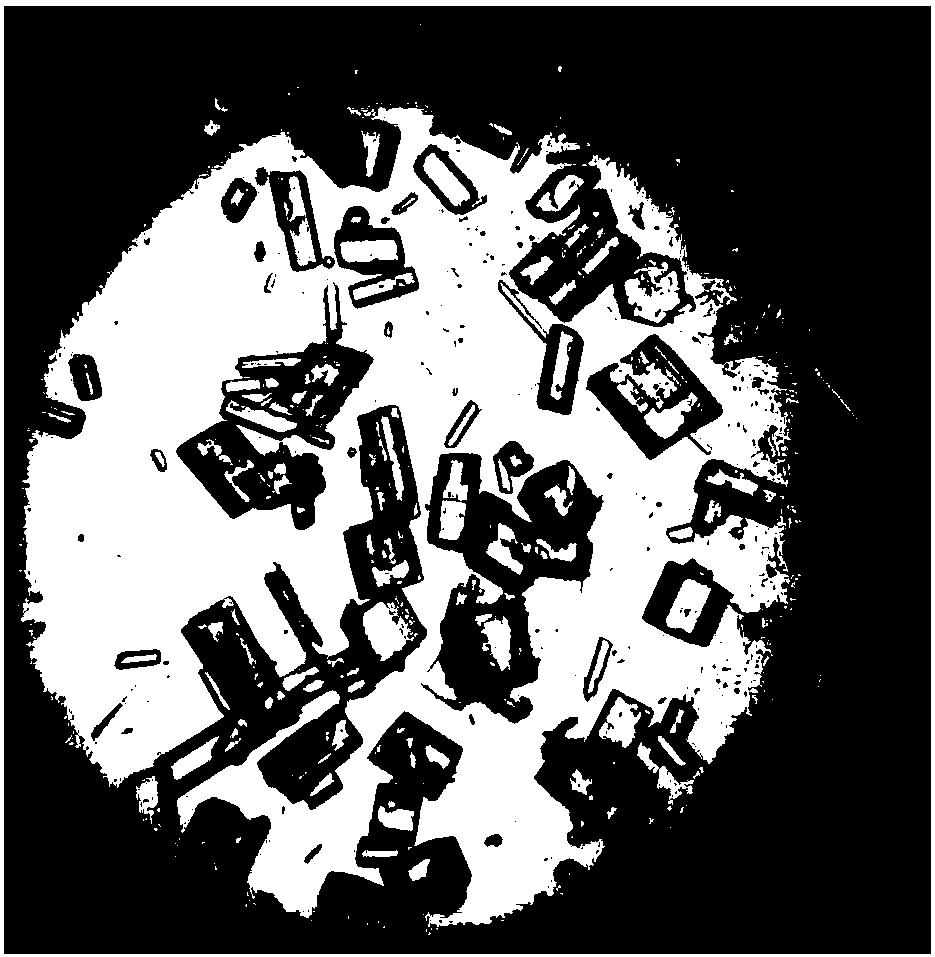

[0056] Aluminum sulfate and citric acid are provided as the crystal transformation agent, the aluminum sulfate and citric acid powder are ground to 100 mesh, and the 100 mesh aluminum sulfate powder and citric acid powder are mixed uniformly in a ratio of 1:0.2 by mass ratio to obtain the transformation Crystal agent powder; provide desulfurized dihydrate gypsum powder with a water content of 12% and a particle size range of 0.03-0.1mm; put the crystal modifier powder and desulfurized dihydrate gypsum powder with a mass of 1.2% of the desulfurized dihydrate gypsum powder into the plow Mix in the knife mixer for 5-10min to uniformity to obtain the mixture; put the mixture into the crystal converter, and the loose volume of the mixture in the crystal converter is 80% of the volume of the crystal converter; 0.4MPa saturated water vapor was introduced into the crystal, and after the temperature in the crystal converter reached 150°C, the heat preservation and pressure were maintain...

Embodiment 3

[0062] Aluminum sulfate and citric acid are provided as the crystal transformation agent, the aluminum sulfate and citric acid powder are ground to 100 mesh, and the 100 mesh aluminum sulfate powder and citric acid powder are mixed evenly in a ratio of 1:0.4 by mass ratio to obtain the transformation Crystal agent powder; provide citric acid dihydrate gypsum powder with a water content of 15% and a particle size of less than 0.1mm; put citric acid dihydrate gypsum powder and citric acid dihydrate gypsum powder with a quality of 0.14% into the plow Mix in the knife mixer for 5-10min to uniformity to obtain the mixture; put the mixture into the crystal converter, and the loose volume of the mixture in the crystal converter is 80% of the volume of the crystal converter; 0.4MPa saturated water vapor was introduced into the crystal, and after the temperature in the crystal converter reached 150°C, the heat preservation and pressure were maintained for 5 hours to obtain mixed crystal...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com