Combined clamping tool

A clamping tool and combined technology, applied in the field of combined clamping tools, can solve the problem of not being able to clamp tempered glass of different specifications, and achieve the effects of preventing scratches on the surface of tempered glass, low manufacturing cost, and increasing stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

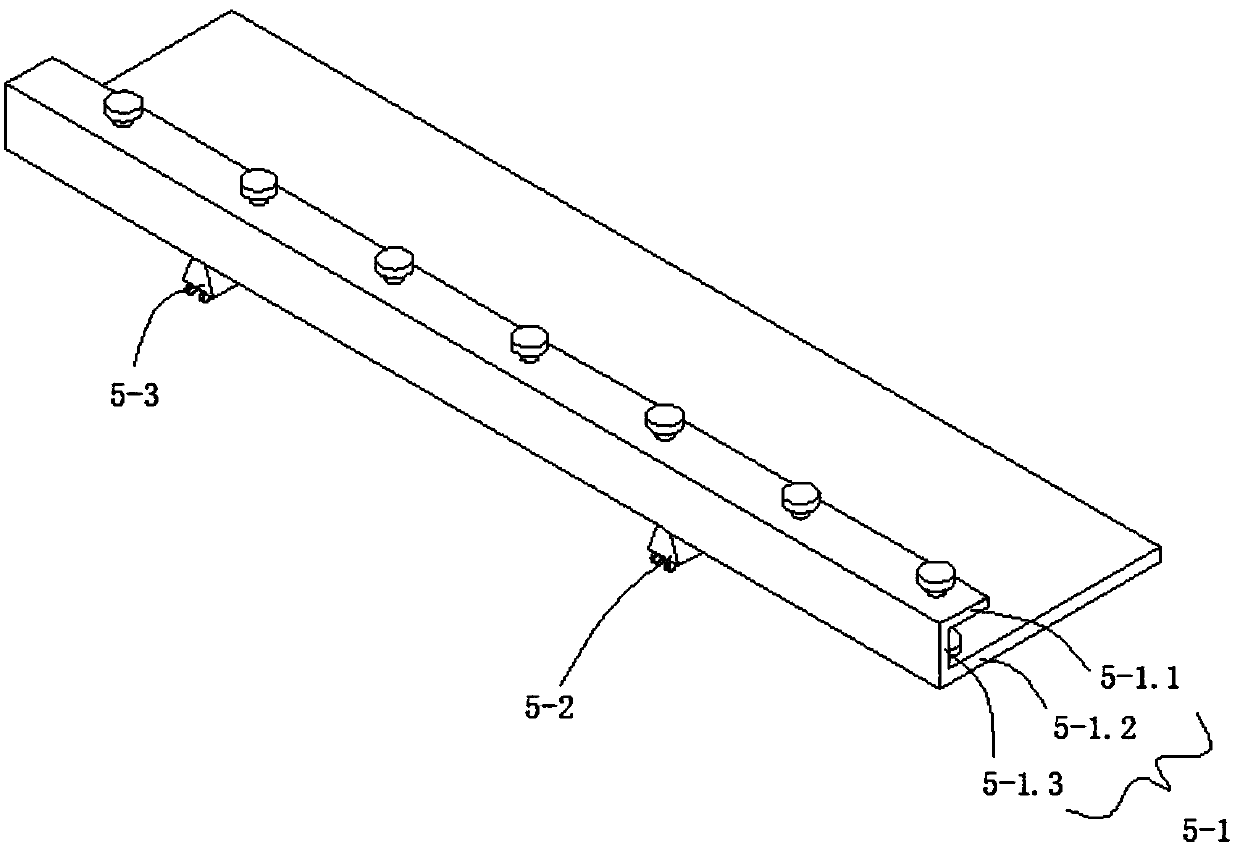

[0020] like Figures 1 to 2 As shown, this embodiment provides a combined clamping tool, including a workbench 1, which is characterized in that the left and right ends of the upper surface of the workbench 1 are respectively provided with an adjustable clamping seat 5 and a fixed clamping seat 2, and the workbench 1 is provided with chute A1-3 and chute B1-2 parallel to each other, chute A1-3 and chute B1-2 are non-return grooves with a large top and a small bottom, and the adjustable clamping seat 5 includes an opening facing right The bending plate assembly 5-1, the bottom of the bending plate assembly 5-1 is provided with the roller assembly A5-3 and the roller assembly B5-2 respectively matched with the chute A1-3 and the chute B1-2, the bending plate assembly 5-1 is provided with a pressing assembly 4.

[0021] In this embodiment, by adjusting the adjustable clamping seat to control the distance between the adjustable clamping seat and the fixed clamping seat, after rea...

Embodiment 2

[0023] This embodiment is further optimized on the basis of embodiment 1, specifically:

[0024] The right edge of the workbench 1 is provided with an L-shaped support frame 3, the support frame 3 includes a vertical plate 3-1 fixed on the edge of the workbench 1, and the upper edge of the vertical plate 3-1 is connected with a horizontal plate 3-2. The fixed clamping seat 2 includes a lower clamping plate 2-3 fixed on the workbench 1 and an upper clamping plate 2-2 that can move up and down above the lower clamping plate 2-3, and the lower surface of the horizontal plate 3-2 A lifting mechanism 2-1 that drives the upper clamping plate 2-2 to move up and down is provided.

[0025] The lifting mechanism 2-1 is a telescopic oil cylinder.

[0026] The bent plate assembly 5-1 includes an upper plate 5-1.1, a vertical plate 5-1.3 and a lower plate 5-1.2, the upper plate 5-1.1 and the lower plate 5-1.2 are arranged in parallel, and the width of the upper plate 5-1.1 Smaller than t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com