Rotating table base plate for large stone cutting machine

A cutting machine and rotary table technology, applied in stone processing tools, stone processing equipment, work accessories, etc., can solve the problems of loose connection parts, contamination of the bottom surface, deviation of the operation process, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

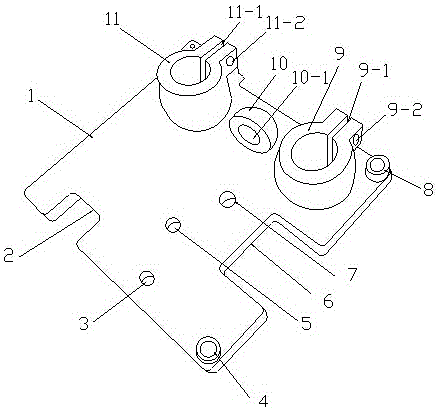

[0010] As shown in the figure, the present invention includes a main body 1. The main body 1 is set as a cuboid structure, and a first notch card slot 2 and a second notch card slot 6 are respectively provided on the lower side and the right side thereof. The first through hole 3, the second through hole 5 and the third through hole 7 are respectively provided, and the lower right corner and the upper right corner of the body 1 are respectively provided with a first cylinder foot 4 and a second cylinder foot 8, The left and right sides above the body 1 are respectively provided with a first cylindrical connecting hole 11 and a second cylindrical connecting hole 9, and the right side of the two cylindrical connecting holes is provided with a square gap, respectively The first notch 11-1 and the second notch 9-1 are provided with internally threaded holes below...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com