Thin metal belt ring rolling mill

A thin metal and ring technology, applied in metal rolling and other directions, can solve the problems of low rolling efficiency, metal ring offset, poor stability, etc., to improve product forming accuracy and rolling efficiency, and ensure consistency and stability. Precision control, the effect of reducing human factors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

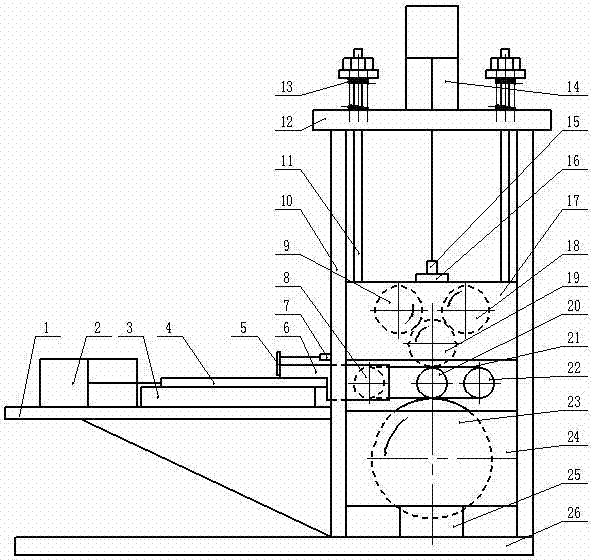

[0019] The present invention will be further described below with reference to the accompanying drawings and specific embodiments.

[0020] like figure 1 As shown, the metal thin strip ring rolling mill of the present invention includes a base 26 on which a bracket composed of four uprights 10 and beams 12 is arranged. A lower support seat 24 and an upper support seat 17 are arranged in the bracket, the lower support seat is located under the upper support seat, the lower support seat 24 is provided with a lower rolling roller 23, and the lower rolling roller is connected with the main motor and is driven by the main motor. Roller turns. Guide chutes are provided inside the four uprights 10, and the upper support base 17 can slide up and down along the uprights guide chute. The upper support base 17 is provided with a left pressure roller 9, a right pressure roller 18 and an upper floating pressure roller 19 of the same size. The left pressure roller 9 and the right pressure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com