Polygonal morphology PtCoFe alloy nano-particles and preparation method of nano-particles

A technology of alloy nanoparticles and alloy nanoparticles, applied in the direction of nanotechnology, nanotechnology, metal processing equipment, etc., can solve the problems of high price, short life, easy poisoning of Pt nanostructure catalysts, etc., and achieve high active site density and wide The effect of applying the foreground

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

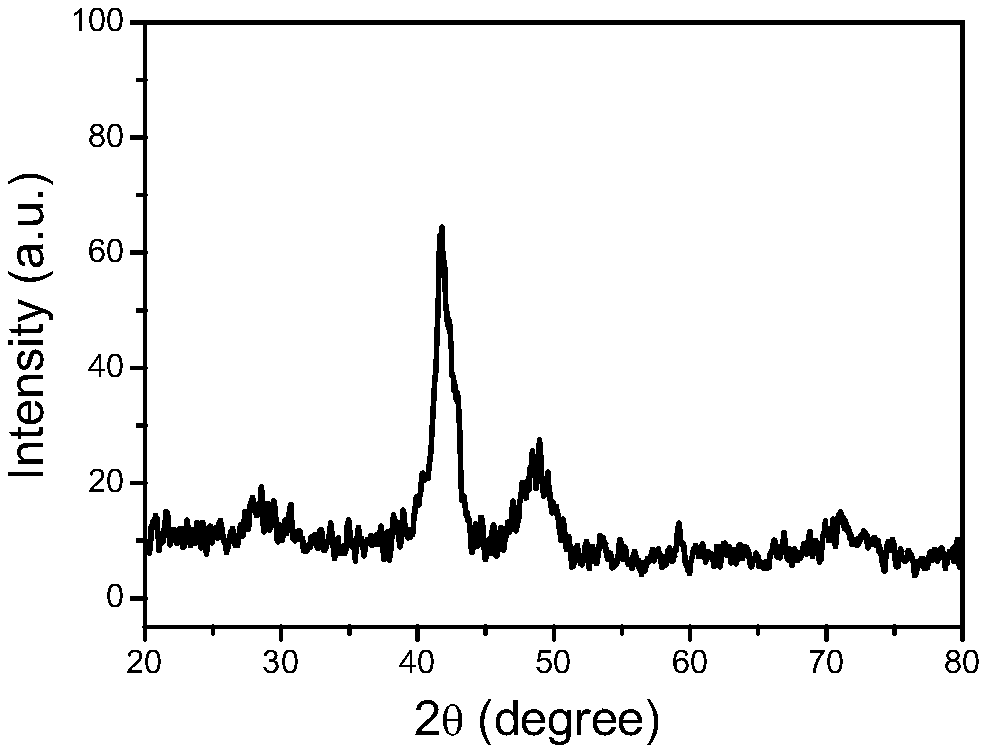

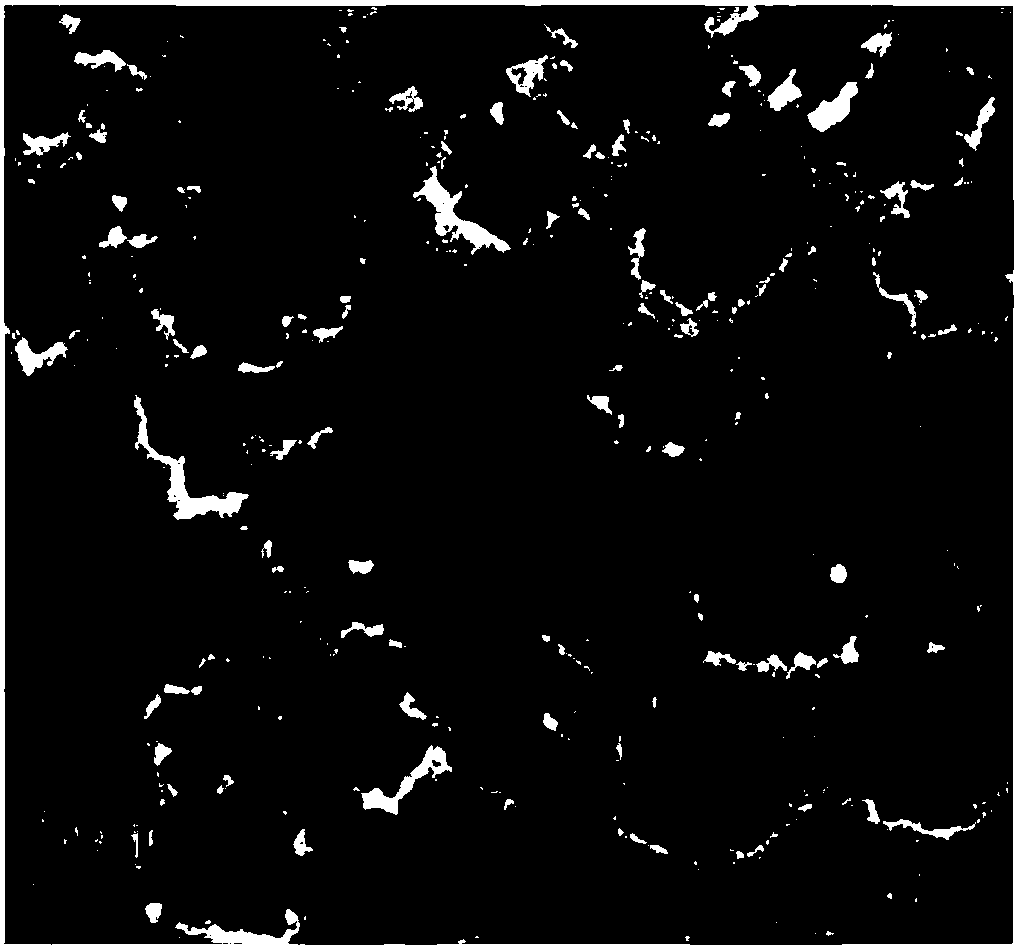

[0023] Measure 1.0mL chloroplatinic acid (19.3mmol / L), 4.0mL concentration is the cobalt chloride of 1.66mmol / L and 3.0mL concentration is the iron trichloride aqueous solution of 1.66mmol / L in the 30ml reactor, then add poly Vinylpyrrolidone K30, hexadecyltrimethylammonium bromide CTAB and NaBr are stirred and dissolved with a magnetic stirrer, and then the air in the reactor is exhausted with hydrogen, and 0.8MPa hydrogen is introduced into the reactor, and then heated at 200°C The reaction is carried out under heating, and after the reaction is completed, through ethanol centrifugal washing, freeze-drying and other processing steps, the polygonal PtCoFe alloy nanoparticles (such as figure 2 Shown), wherein, the consumption range of polyvinylpyrrolidone K30 is 210mg, the consumption range of cetyltrimethylammonium bromide is 60mg, and the consumption of NaBr is identical with the consumption of cetyltrimethylammonium bromide.

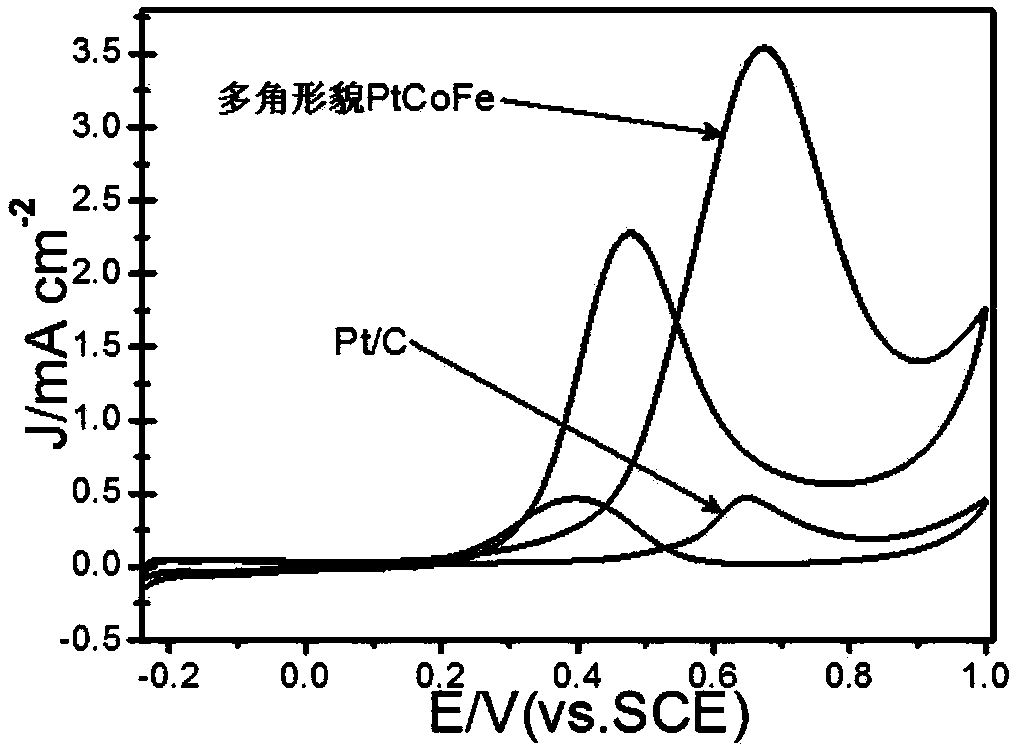

[0024] Methanol (formic acid) electro-oxidatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com