Long stapled cotton seed coating agent and use method for same

A technology of long-staple cotton and a coating agent, applied in the field of seed coating, can solve the problems of increasing the yield of incomplete long-staple cotton, affecting the production and development of long-staple cotton, failing to achieve the best effect, etc., and achieving a firm and uniform coating effect. , the preparation cost is low, and the effect of promoting absorption and utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

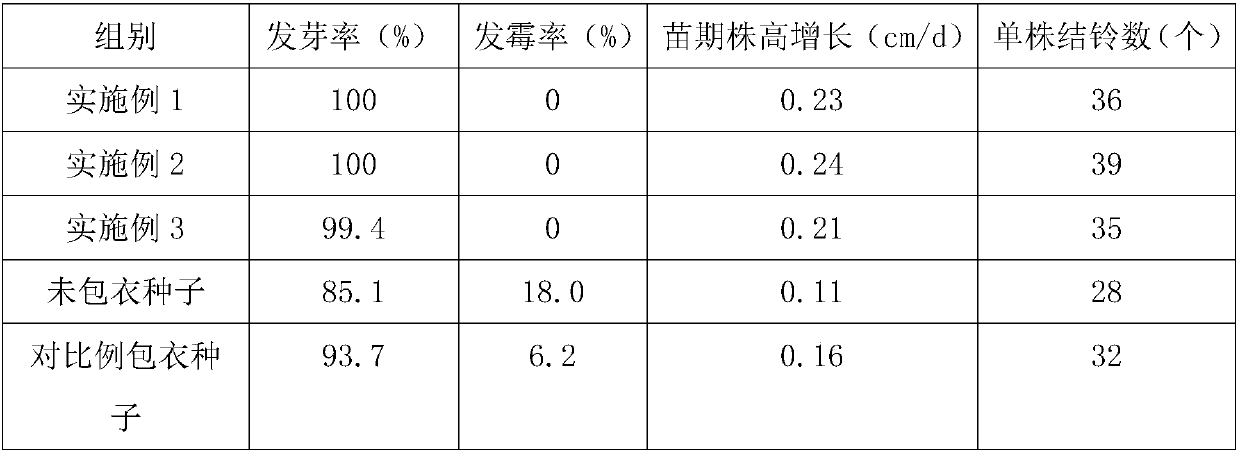

Examples

Embodiment 1

[0035] A long-staple cotton seed coating agent, the following raw materials are weighed: 20kg of modified rice husk powder, 4kg of starch adhesive, 1kg of attapulgite powder, 2kg of Eupatorium adenophorum extract, 1kg of zinc sulfate, 2kg of silkworm excrement, Stone powder 3kg, sodium bicarbonate 1kg, clavulanic acid 1kg, bactericidal and insect repellent 1kg, growth regulator 1kg, dispersant 1kg, film-hanging agent 6kg and water 25kg;

[0036] Preparation of modified rice husk powder: Weigh 20kg of rice husk, 0.5kg of sodium sulfite, 0.6kg of allyl heptanoate, 0.4kg of 2-methylimidazole, 1kg of polycarboxylate superplasticizer, 0.1kg of ammonium persulfate, seaweed Calcium acid 0.8kg, nepheline powder 1kg and sandan oil 2kg; the modified rice husk powder is obtained through the following steps: rice husk is crushed into 40 mesh particles, sprayed with sandan oil while stirring, and placed for 2 hours after mixing evenly , and then mixed with other remaining ingredients, heat...

Embodiment 2

[0046] A long-staple cotton seed coating agent, the following raw materials are taken by weighing: 25kg of modified rice husk powder, 6kg of starch adhesive, 2kg of attapulgite powder, 3kg of Eupatorium adenophorum extract, 2kg of zinc sulfate, 3kg of silkworm excrement, Stone powder 4kg, sodium bicarbonate 2kg, clavulanic acid 1.5kg, bactericidal and insect repellent 2kg, growth regulator 3kg, dispersant 2kg, film-hanging agent 7kg and water 30kg;

[0047] Preparation of modified rice husk powder: Weigh 25kg of rice husk, 1kg of sodium sulfite, 0.9kg of allyl heptanoate, 0.6kg of 2-methylimidazole, 1.5kg of polycarboxylate superplasticizer, 0.2kg of ammonium persulfate, seaweed Calcium acid 1kg, nepheline powder 2kg and sandan oil 3kg; This modified rice husk powder is obtained through the following steps: rice husk is crushed into 60 mesh particles, sprayed with sandan oil while stirring, and placed for 3h after mixing evenly. Then mix with other remaining ingredients, heat ...

Embodiment 3

[0057] A long-staple cotton seed coating agent, which takes the following raw materials: 30kg of modified rice husk powder, 8kg of starch adhesive, 3kg of attapulgite powder, 4kg of Eupatorium adenophorum extract, 3kg of zinc sulfate, 4kg of silkworm excrement, Stone powder 5kg, sodium bicarbonate 3kg, clavulanic acid 2kg, bactericidal and insect repellent 3kg, growth regulator 5kg, dispersant 3kg, film-hanging agent 8kg and water 35kg;

[0058] Preparation of modified rice husk powder: weigh 30kg of rice husk, 1.5kg of sodium sulfite, 1.2kg of allyl heptanoate, 0.8kg of 2-methylimidazole, 2kg of polycarboxylate superplasticizer, 0.3kg of ammonium persulfate, seaweed Calcium acid 1.2kg, nepheline powder 3kg and sandan oil 4kg; the modified rice husk powder is obtained through the following steps: rice husk is crushed into 80 mesh particles, sprayed with sandan oil while stirring, and placed for 4 hours after mixing evenly , and then mixed with other remaining ingredients, heat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com