Honeycomb-shaped wet-method black-silicon texturing structure and preparing method thereof and black-silicon cell and preparing method thereof

A honeycomb and black silicon technology, which is applied in the manufacture of circuits, electrical components, and final products, can solve the problems of high procurement cost of new equipment, idle polycrystalline texturing equipment, and large space occupied by equipment, and achieve large-scale market promotion Good value, good appearance and performance, and the effect of saving space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

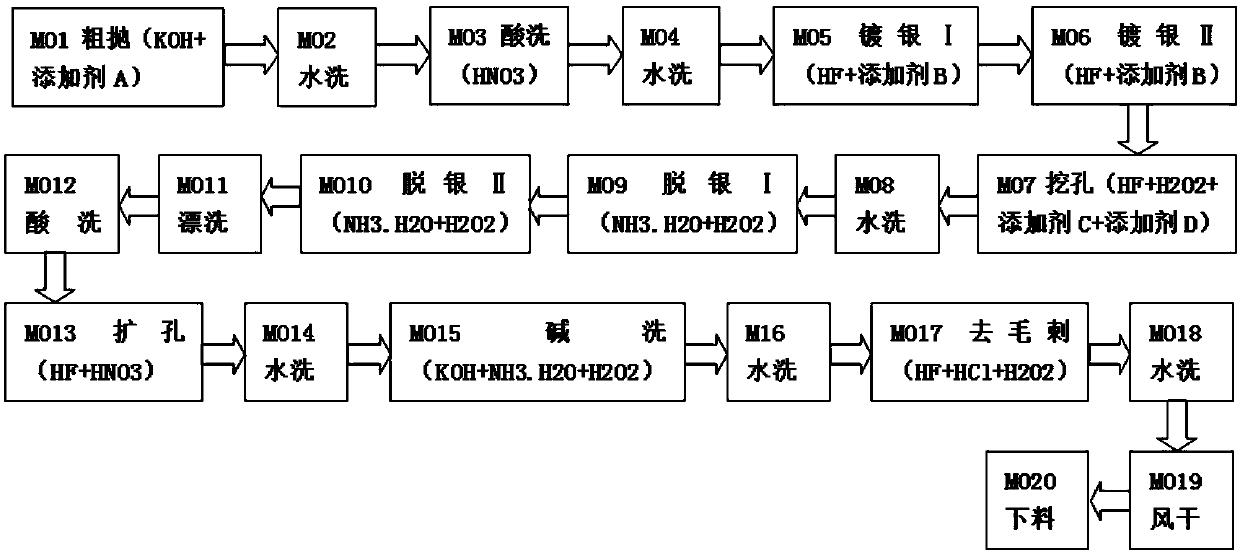

[0030] A method for preparing a honeycomb wet-process black silicon textured structure, comprising:

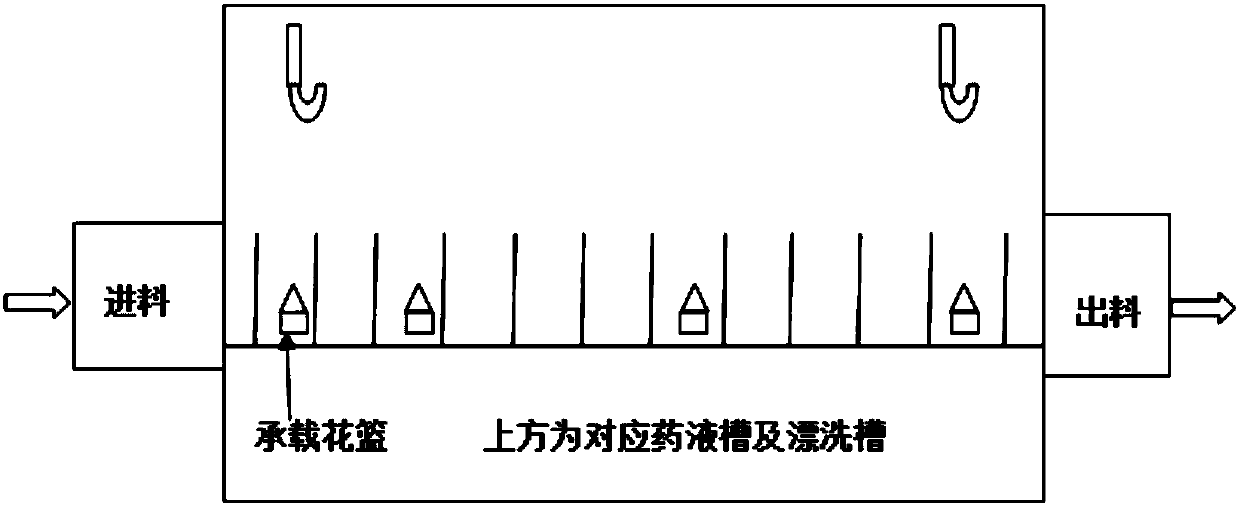

[0031] Digging diamond wire polysilicon wafers through wet-process black silicon trough-type hole-digging equipment;

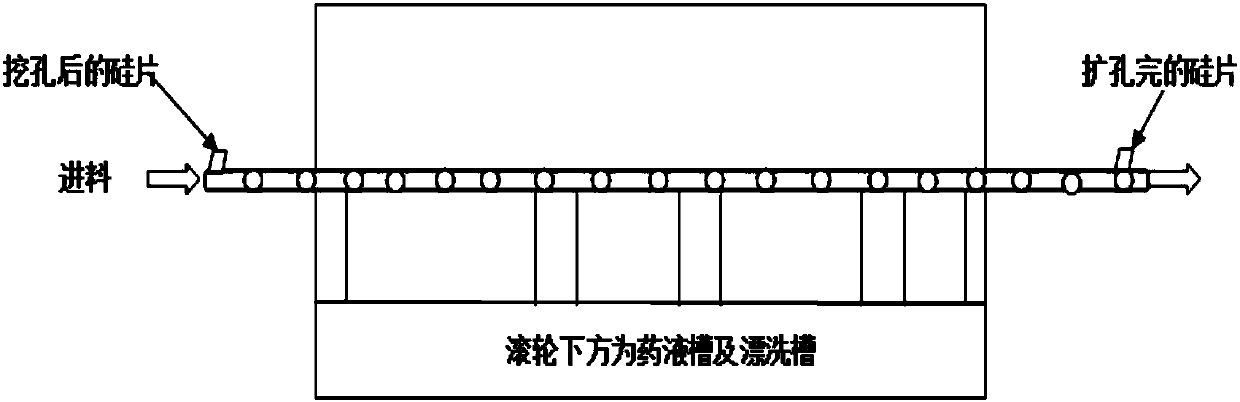

[0032] The product after the completion of the hole digging operation is reamed through the RENA chain equipment, and NH is added to the alkali washing liquid in the alkali washing tank of the RENA chain equipment 3 .H 2 O and H 2 o 2 , add H to the pickling solution in the pickling tank 2 o 2 .

[0033] Utilize the existing polycrystalline battery production line, add front-end digging equipment, and combine polycrystalline RENA texturing equipment to realize the new technology of wet-process black silicon preparation with slot machine digging and chain RENA machine hole expansion. Not only can the idle texturing equipment be reused efficiently, but also greatly save the space occupied by the equipment, and at the same time, an ideal honeycomb wet-proce...

Embodiment 1

[0057] This embodiment provides a black silicon battery, which is prepared by the following method:

[0058] First, the diamond wire polysilicon wafers are dug through the wet-process black silicon trough-type hole-digging equipment. The hole digging operation is to carry out rough throwing, first water washing, first pickling, second water washing, first silver plating, second silver plating, and hole digging in the wet black silicon tank type hole digging equipment. , the third water washing, the first desilvering, the second desilvering, rinsing and the second pickling.

[0059] Among them, the temperature of rough polishing is 60°C, and the time of rough polishing is 180S; the first washing, the second washing and the third washing are all carried out at room temperature, and the washing time is 120S; the first pickling It is pickled by nitric acid at room temperature for 60S; the first silver plating and the second silver plating are carried out at room temperature in th...

Embodiment 2

[0064] This embodiment provides a black silicon battery, which is prepared by the following method:

[0065] First, the diamond wire polysilicon wafers are dug through the wet-process black silicon trough-type hole-digging equipment. The hole digging operation is to carry out rough throwing, first water washing, first pickling, second water washing, first silver plating, second silver plating, and hole digging in the wet black silicon tank type hole digging equipment. , the third water washing, the first desilvering, the second desilvering, rinsing and the second pickling.

[0066] Among them, the temperature of rough polishing is 75°C, and the time of rough polishing is 200S; the first water washing, the second water washing and the third water washing are all carried out at room temperature, and the washing time is 180S; the first pickling It is pickled by nitric acid at room temperature for 75S; the first silver plating and the second silver plating are carried out at room...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com