Radiation-prevention hoisting hole spout plug structure

A hoisting hole and radiation protection technology, applied in the field of radiation protection, can solve the problems of inability to achieve radiation pollution, lack of radiation protection performance, high cleanliness requirements, etc., and achieves strong radiation and leakage prevention capabilities, wide application range, and simple structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

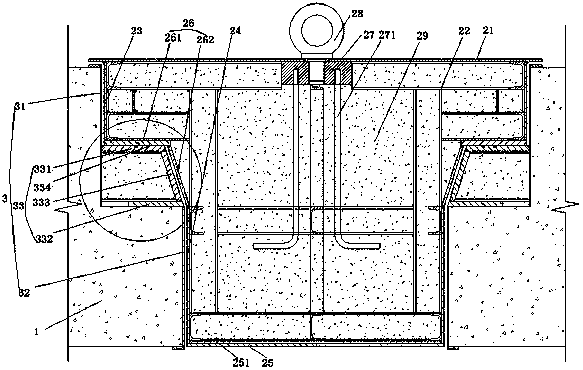

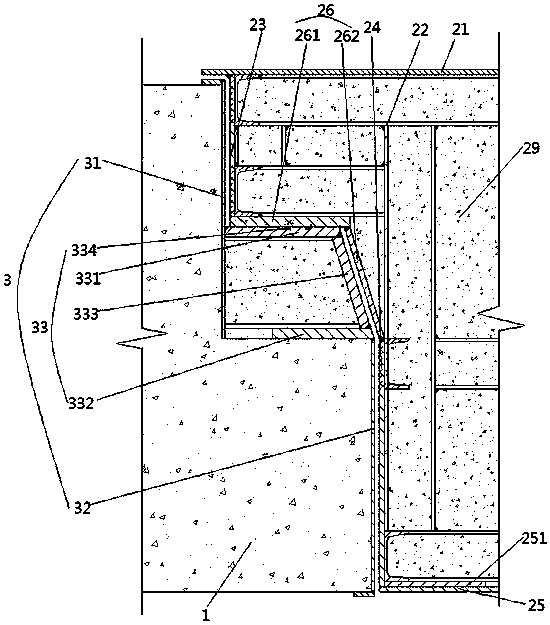

[0020] A kind of anti-radiation hoisting hole plug structure of the present invention, such as figure 1 and figure 2 Shown: including the plug hole in the concrete 1 and the lifting hole plug installed in the plug hole, the plug hole is in the shape of a ladder as a whole, including the upper stage and the lower stage; The steps between them are at right angles; the inner wall of the plug hole is provided with a stainless steel cladding structure 3; the stainless steel cladding structure 3 includes a first upper cylindrical stainless steel cladding plate 31 and a first lower cylindrical stainless steel cladding plate 32, the first upper cylindrical stainless steel cladding plate 31 Coated on the upper stage, the first lower cylindrical stainless steel cladding plate 32 is clad on the lower stage; a trapezoidal spacer 33 is provided on the step between the upper stage and the lower stage, and the trapezoidal spacer 33 includes a first annular stainless steel cladding plate 331...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com