Heating consolidation construction method for arranging electric heating rod in vertical drainage filter tube

A vertical drainage and construction method technology, applied in infrastructure engineering, soil protection, construction, etc., can solve problems such as complex operation, high energy consumption, and unsuitability for large-scale on-site construction, and achieve high waterproof level and convenient connection , The effect of simple construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The technical solutions of the present invention will be further described below in conjunction with specific embodiments.

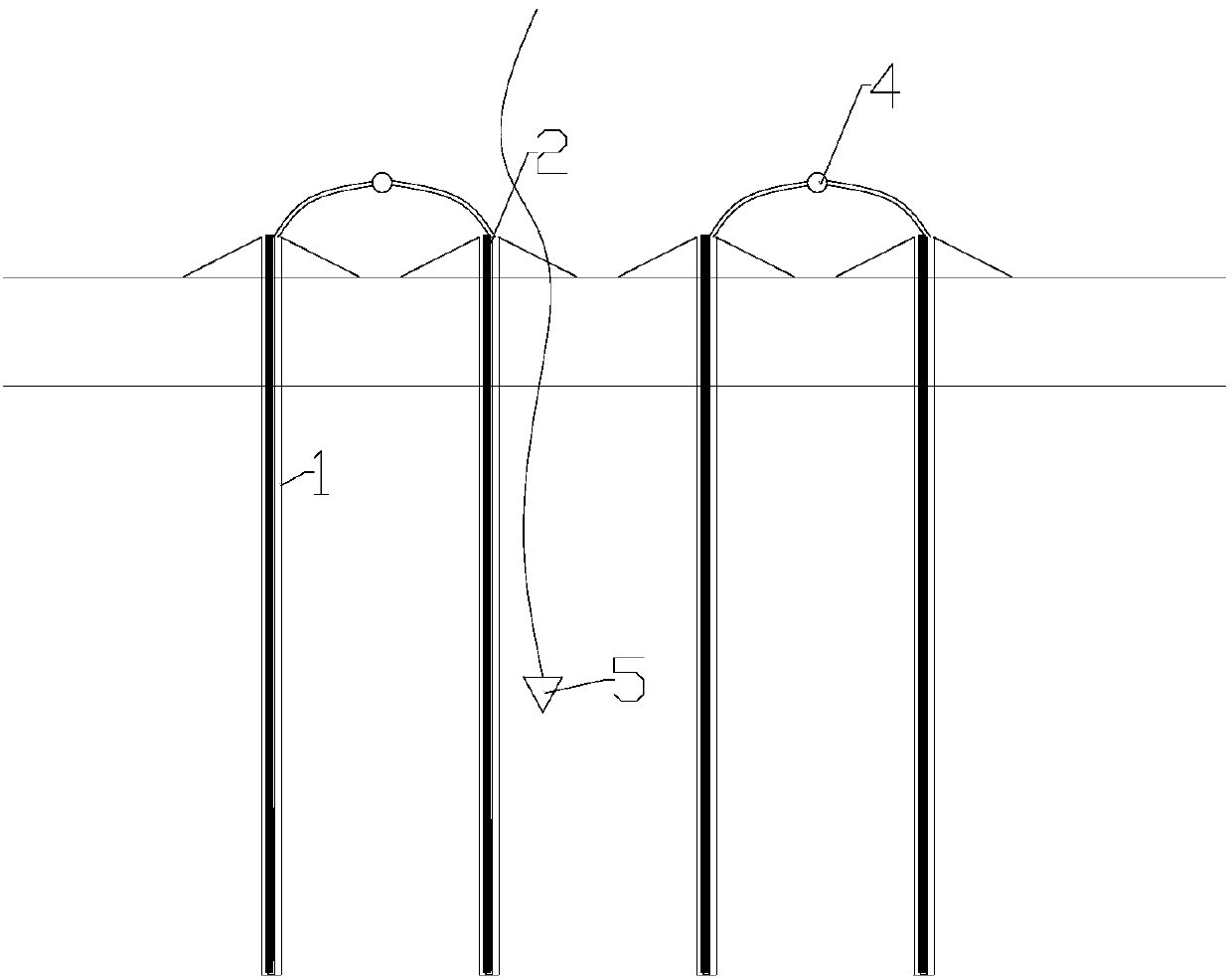

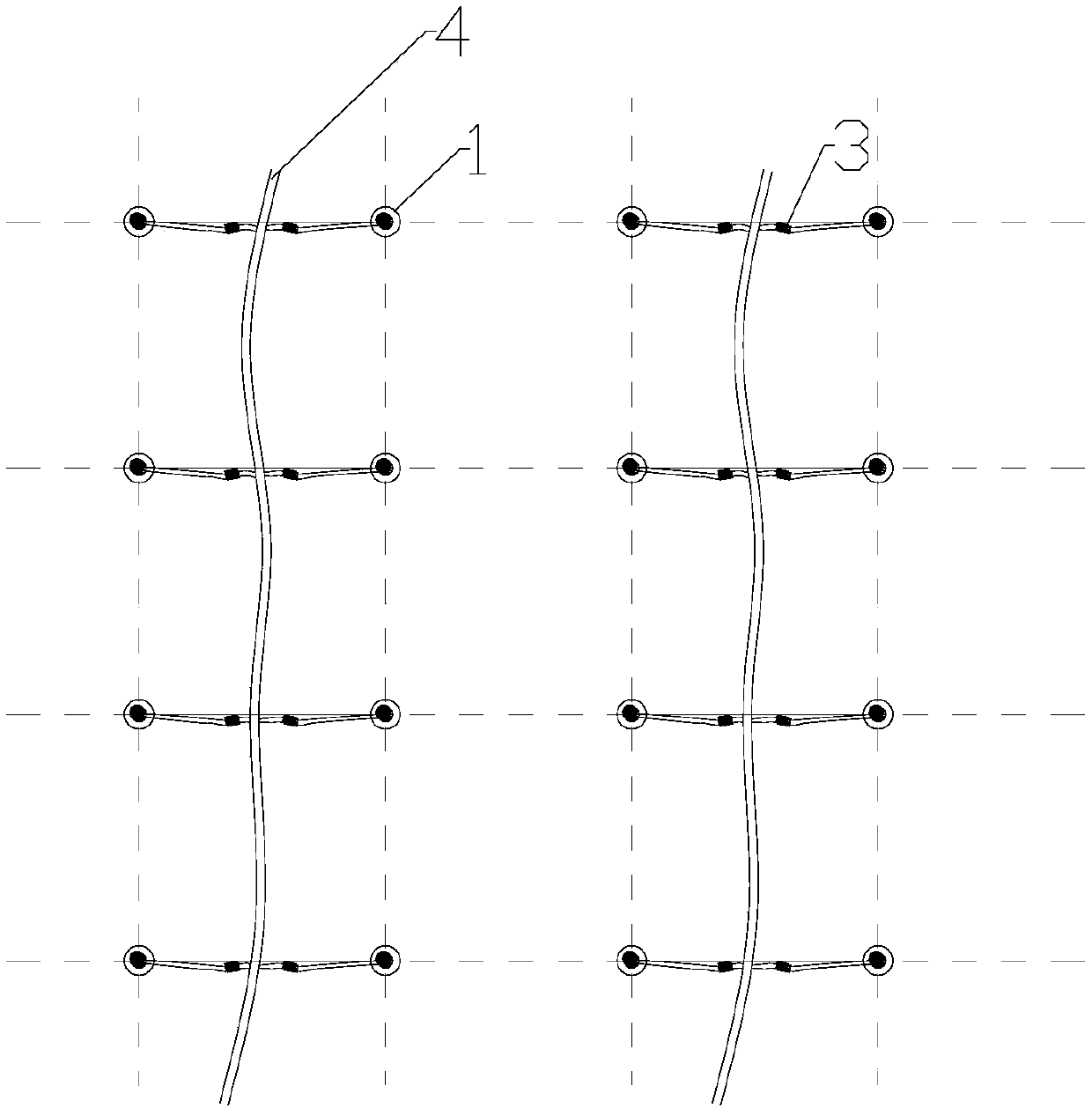

[0026] A heating and consolidation construction method for a vertical drainage filter pipe with a built-in electric heating rod, comprising a vertical drainage filter pipe 1 and an electric heating rod 2 for being built into the vertical drainage filter pipe;

[0027] The vertical drainage filter pipe is composed of a permeable bellows 1-1 and a polyester spunbonded non-woven fabric 1-2 wrapped around the permeable bellows. The permeable bellows are formed of high-density polypropylene (PPR) and have a Corrugated new plastic drainage pipes, the grooves of the permeable corrugated pipes are evenly distributed with 1-3 permeable through holes, and the surroundings of the permeable corrugated pipes are covered with polyester spunbonded non-woven fabrics; the diameter of the vertical drainage filter pipe is preferably 30mm, and other technical indicato...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com