Magnetically-conductive half ring electroplating device

An electroplating device and magnetic conduction technology, applied in the electrolysis process, electrolysis components, etc., can solve the problems of poor plating quality on the surface of the winding position, increased production costs, and low electroplating efficiency, so as to improve electroplating efficiency, reduce labor costs, and operate simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

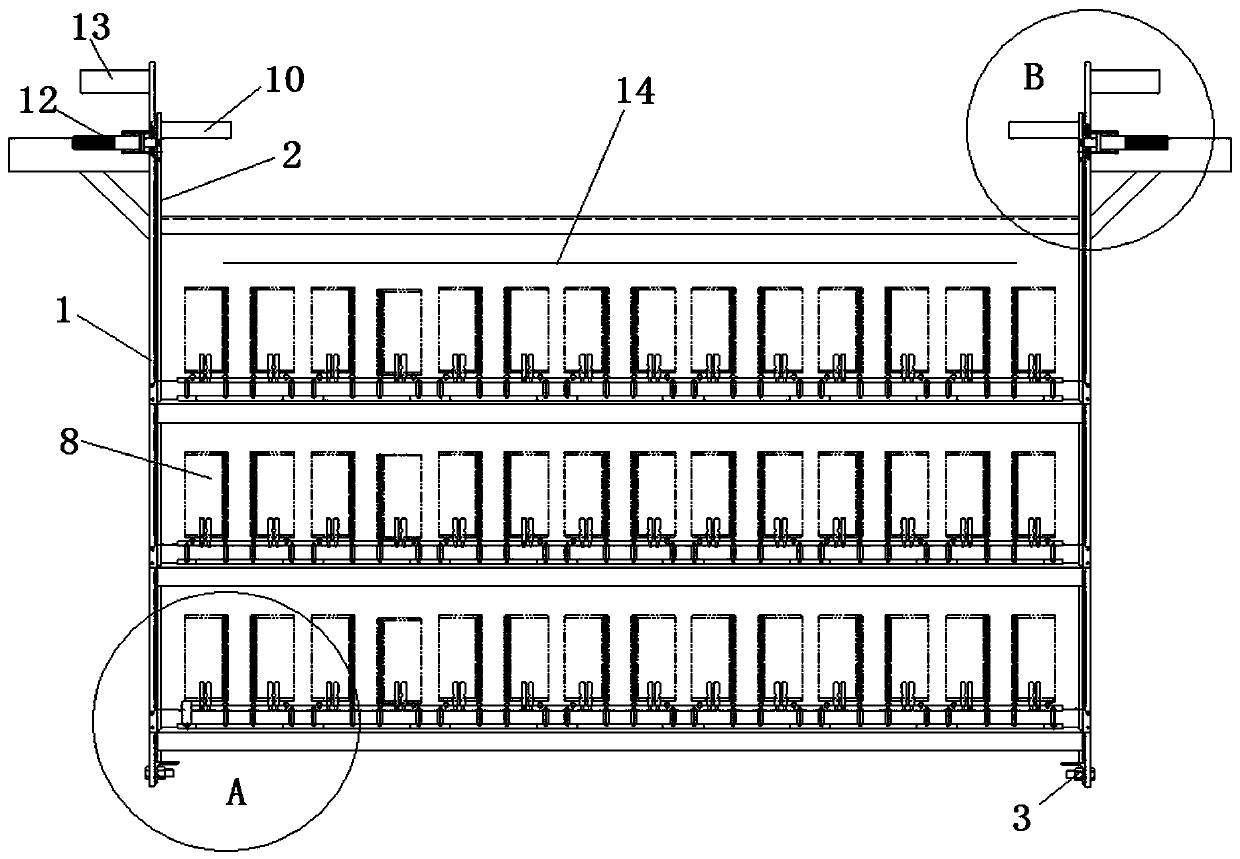

[0036] The specific implementation of the magnetic semi-ring electroplating device of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0037] See attached figure 1 , the magnetic semi-ring electroplating device includes a large bracket 1 and a small bracket 2, the large bracket 1 and the small bracket 2 are rectangular structures, the small bracket 2 can be placed inside the large bracket 1, and a support seat 3 is set on the large bracket 1, and the small bracket 2 The bracket 2 is arranged in the large bracket 1 through the support seat 3, and the support seat 3 includes an angle steel arranged on the inner side of the bottom of the large bracket 1, and the angle steel is located on opposite sides of the short side of the large bracket 1.

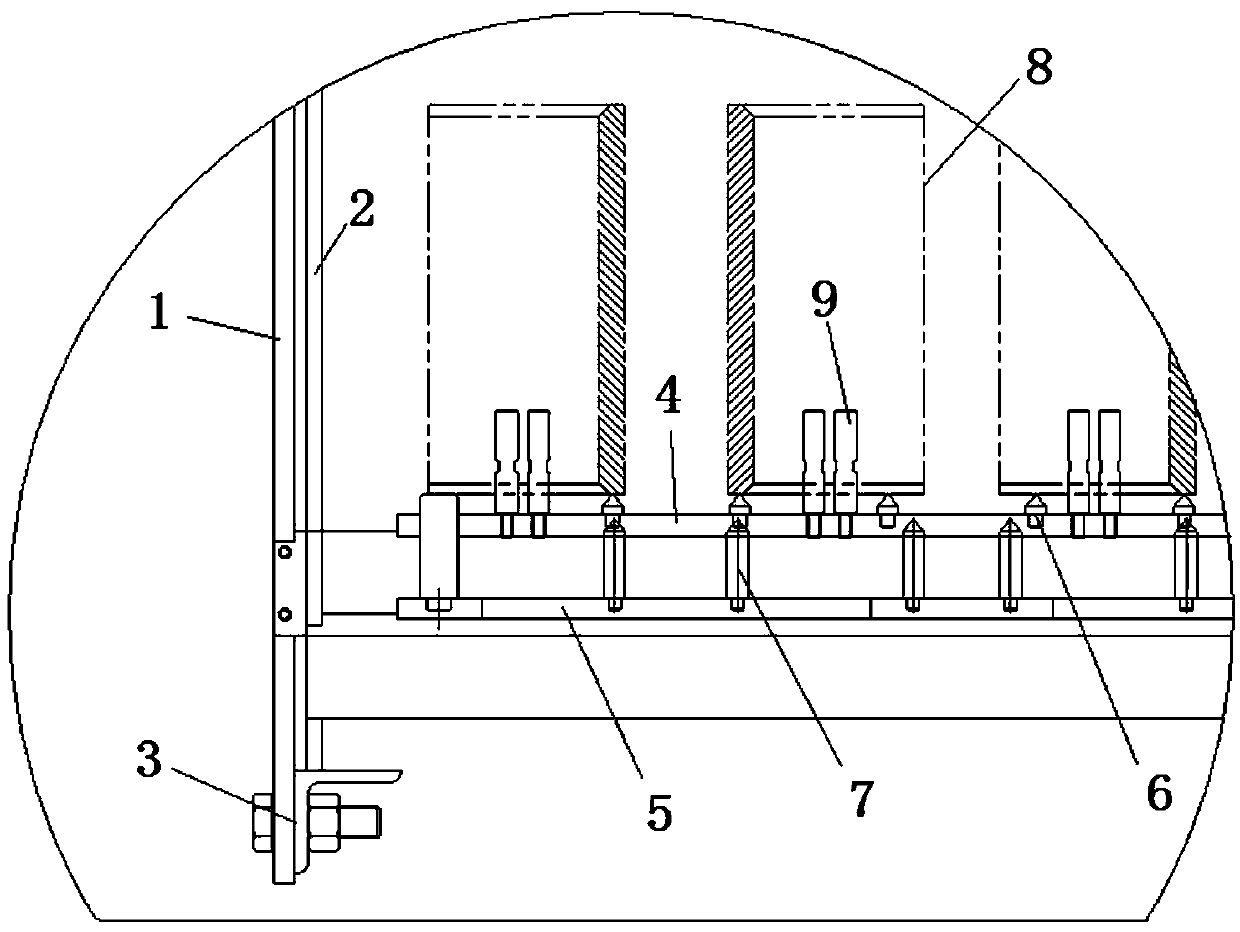

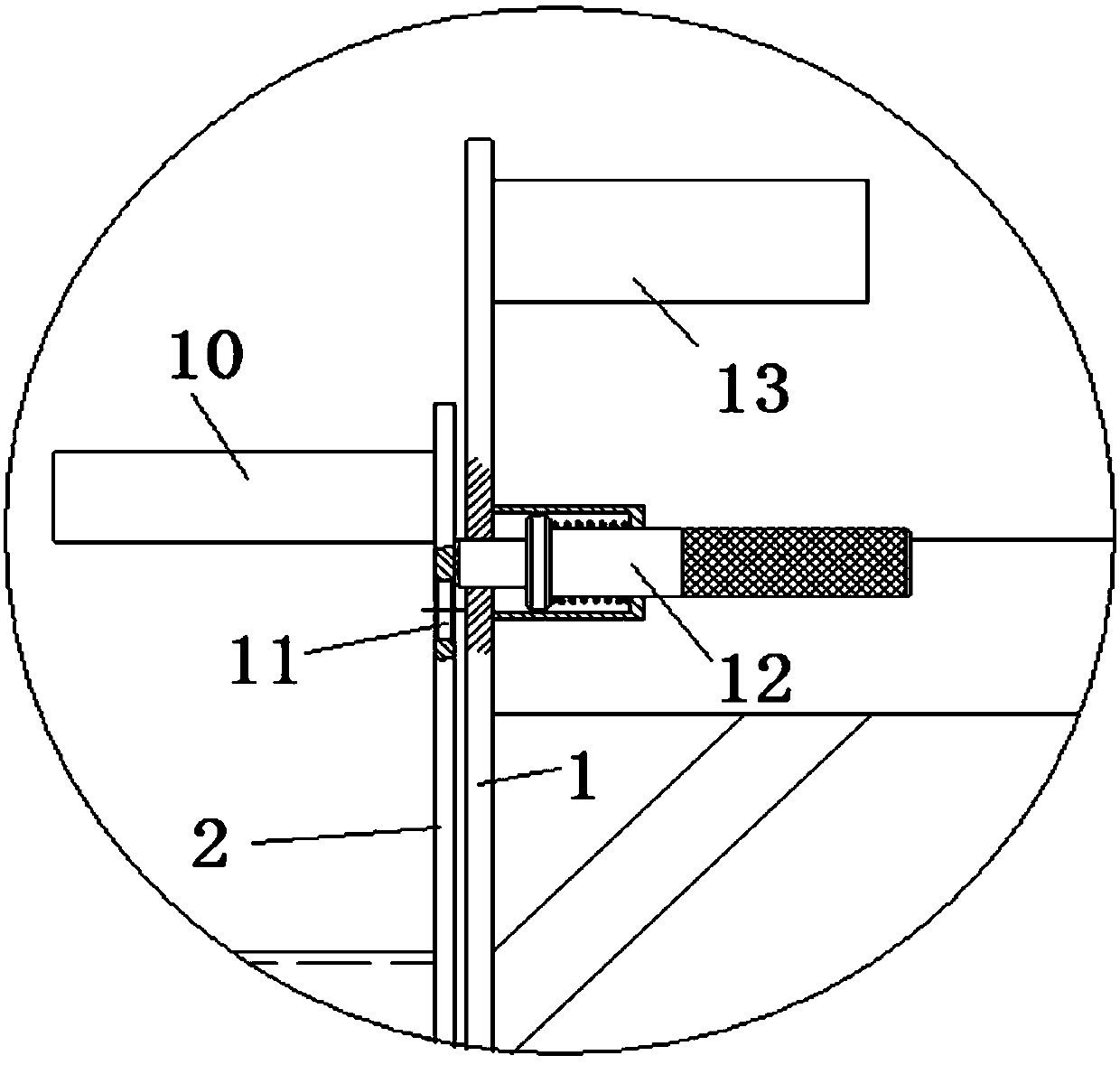

[0038] See attached Figures 1 to 4 , the first support bar 4 is set on the large support 1, the second support bar 5 is set on the small support 2, the second support bar 5 is loca...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com