Horizontal chrome plating bath and chrome plating method

A chrome plating tank, horizontal technology, applied in the field of electroplating equipment and electroplating, can solve the problems of easy tip discharge, tip discharge, inconvenience, etc., and achieve the effects of saving precious metal materials, improving uniformity and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

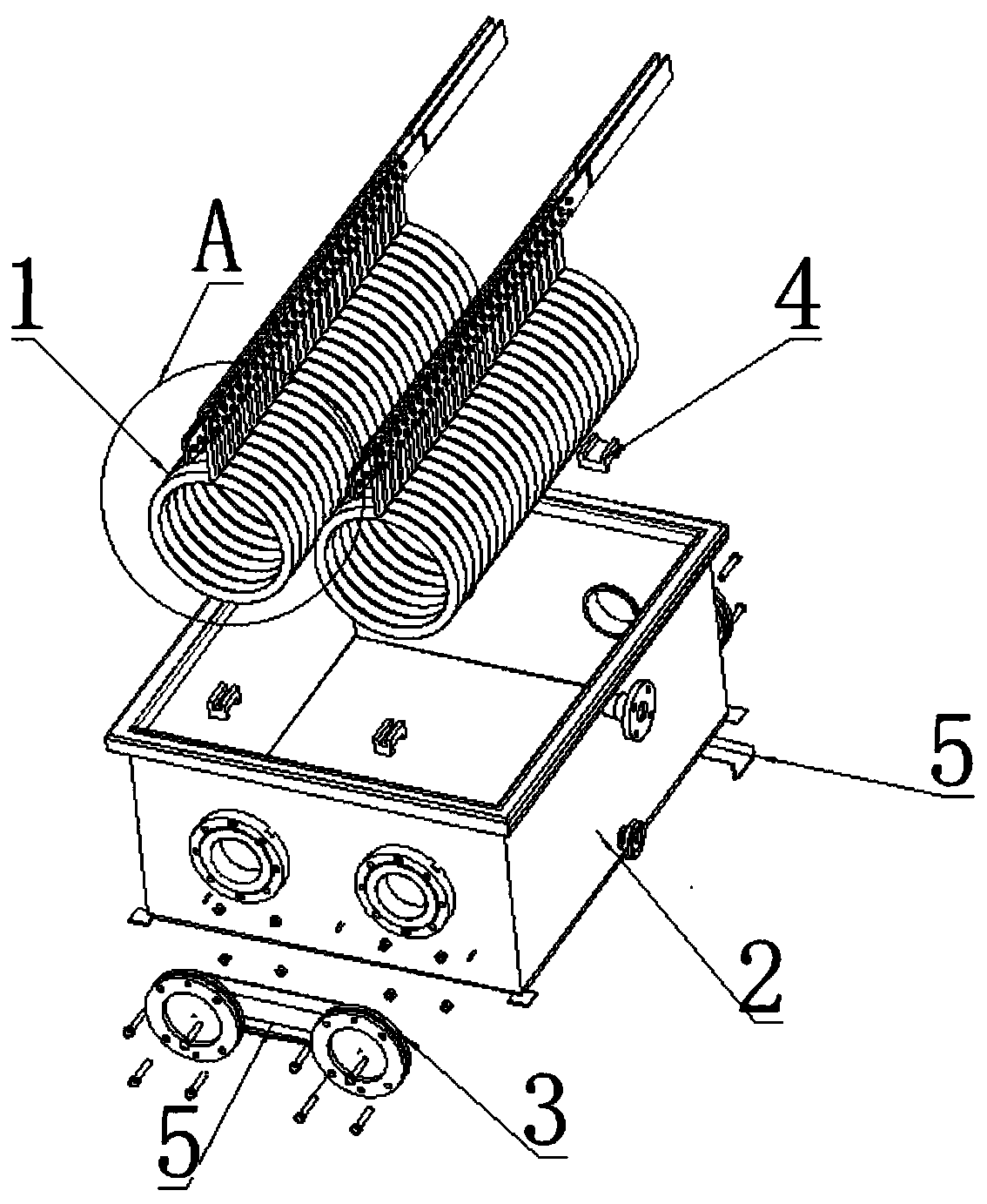

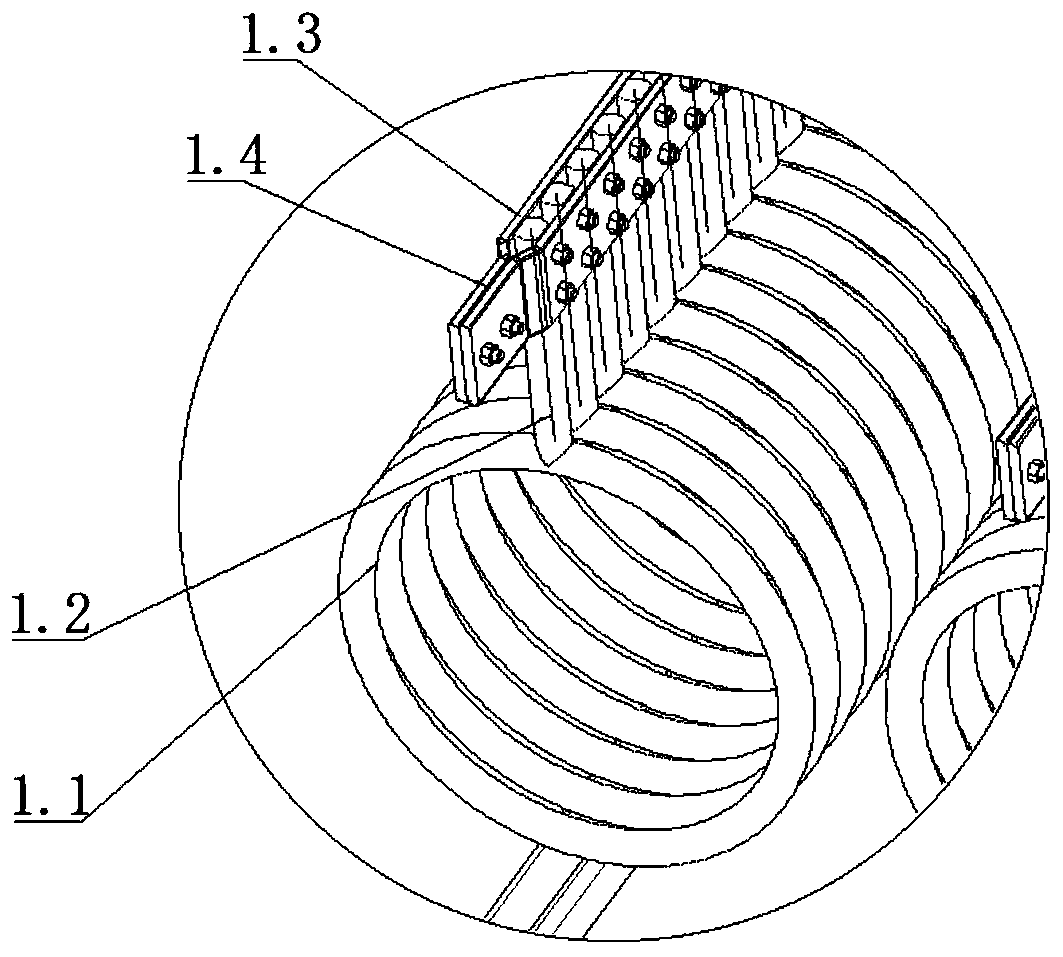

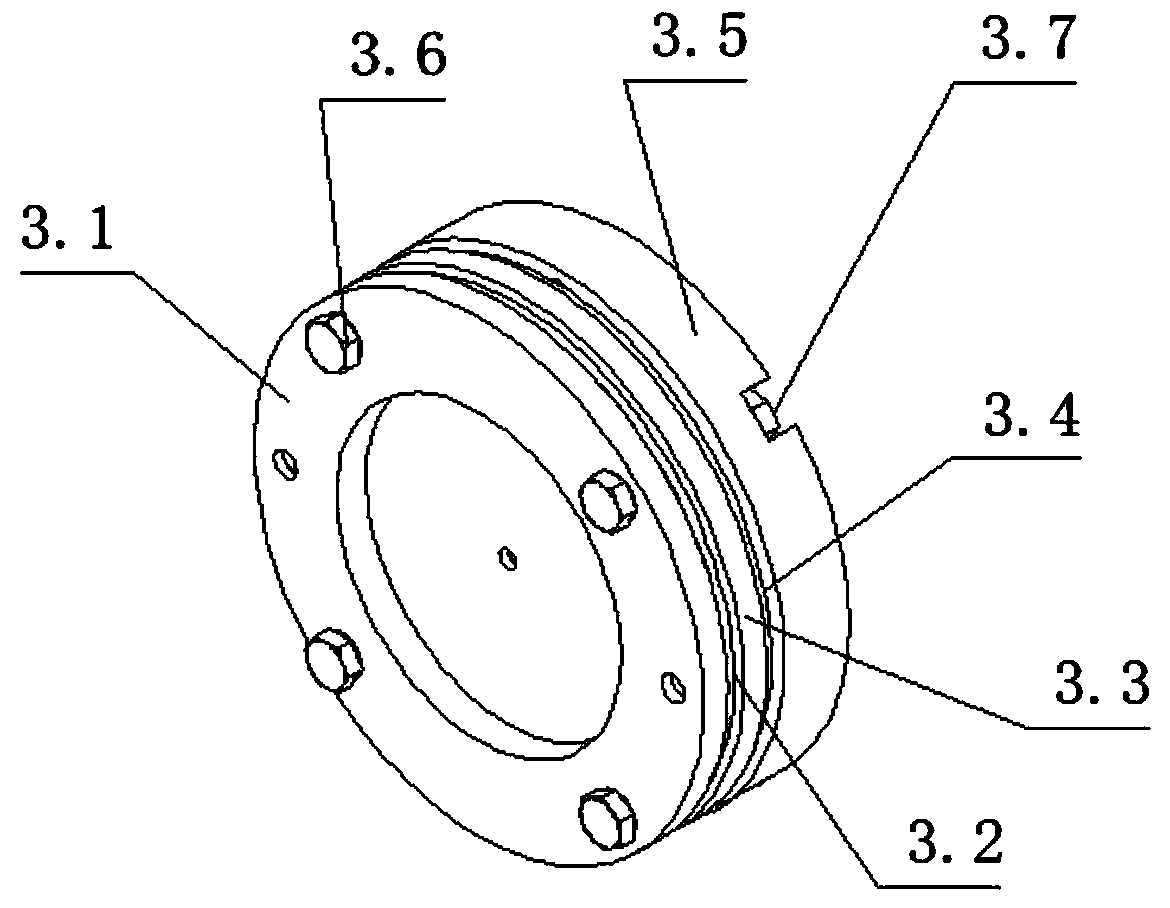

[0025] A kind of horizontal chrome plating tank (see Figure 1-7 ), comprising a tank body 2, a circular passage hole is provided on the side walls at both ends of the tank body 2; a sealing assembly 3 is installed on the side wall outside the passage hole, and a chrome-plated anode assembly 1 is installed on the top of the tank body 2 The chrome-plated anode assembly 1 includes an annular anode ring 1.1 and a suspension beam, the suspension beam includes a pair of beam plates, and the beam plate includes a clamping section 1.3 and fastening sections 1.4 at both ends of the clamping section 1.3; The anode ring 1.1 is provided with a suspension rod 1.2, and the end of the suspension rod 1.2 is fixedly installed betwe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com