Mechanical arm of double gripper structure and control method of mechanical arm

A control method and manipulator technology, which can be applied to manipulators, program-controlled manipulators, manufacturing tools, etc., can solve problems such as the inability to meet the production capacity requirements of battery manufacturers, and achieve the effect of not easily pinching the surface of the battery, adapting to a wide range of convenience, and increasing production capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

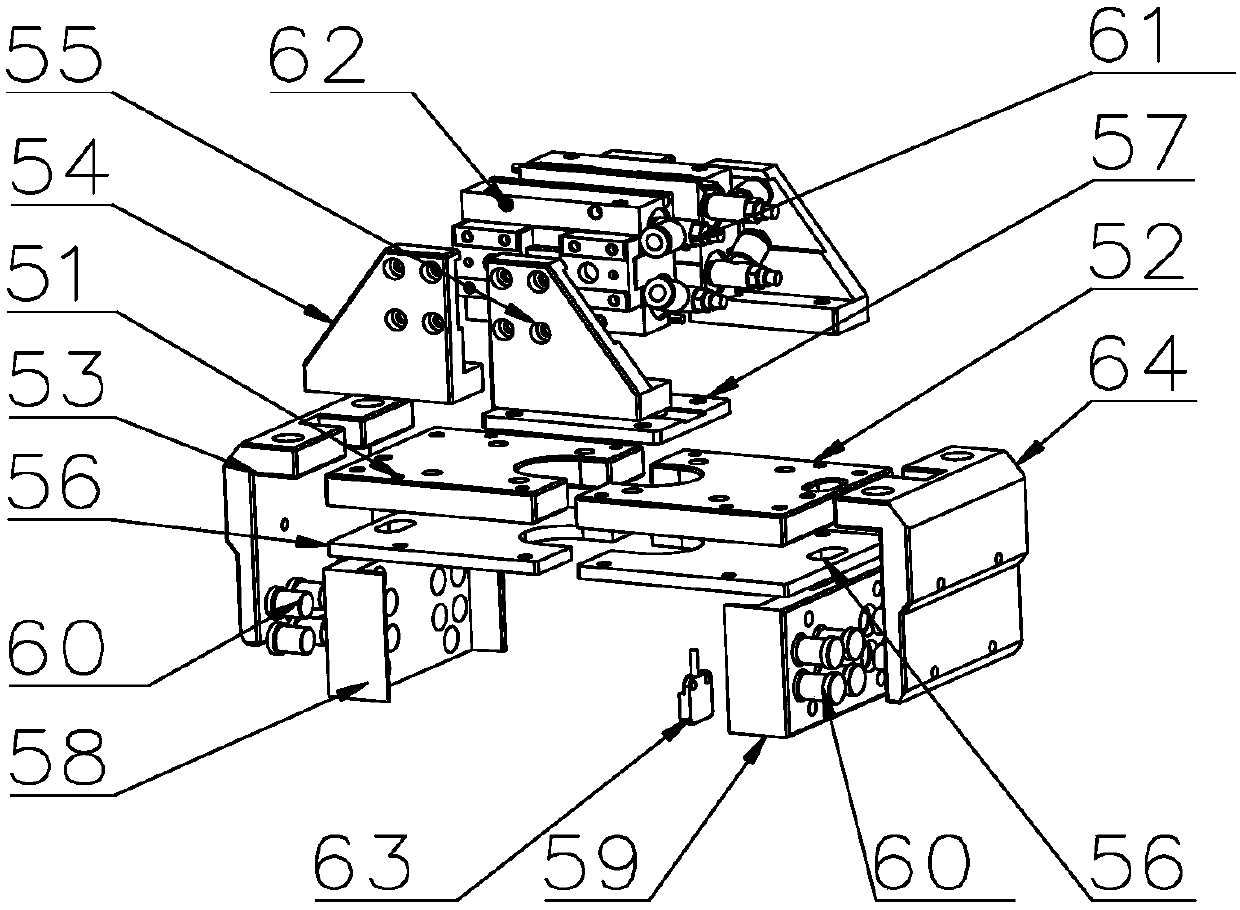

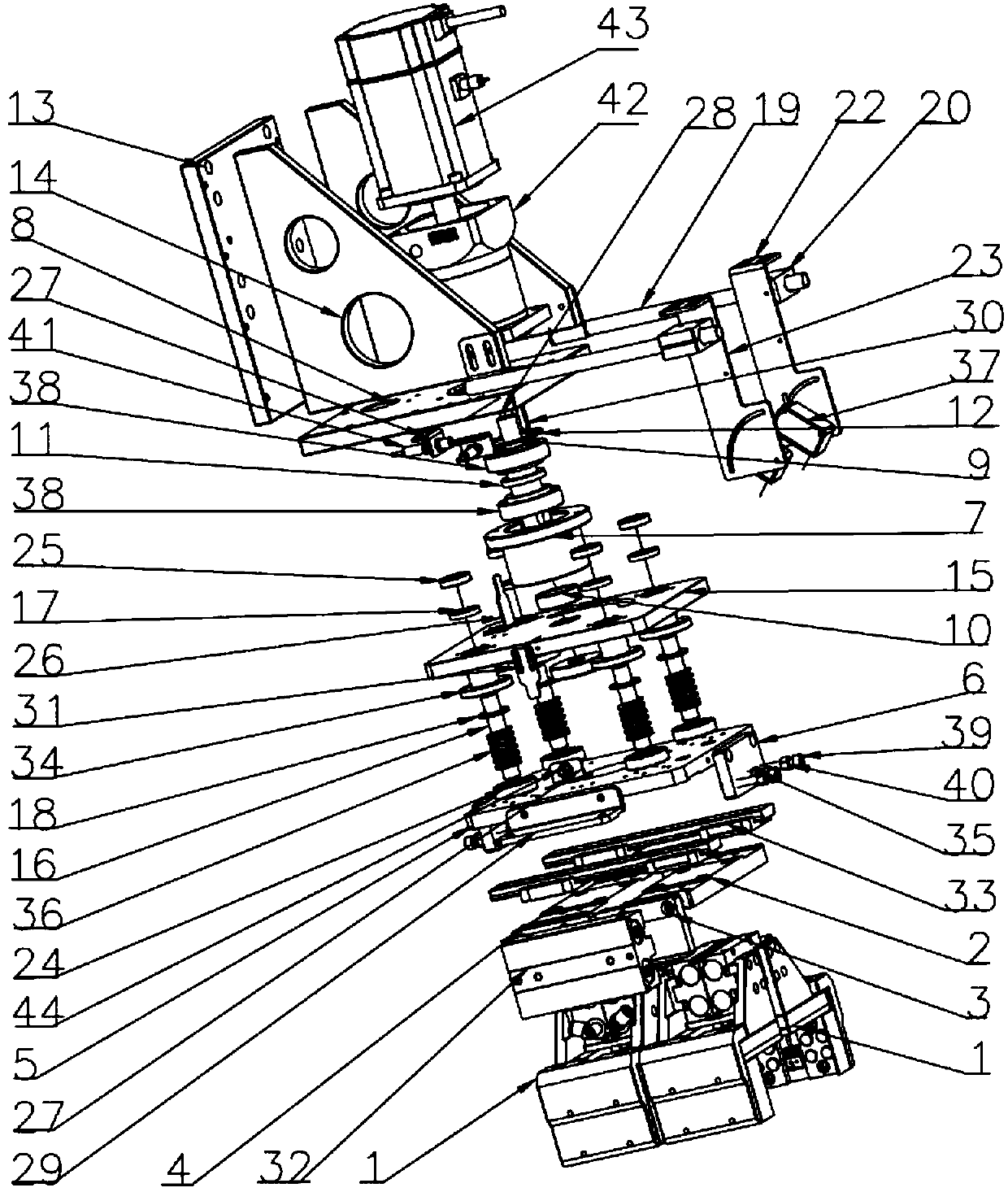

[0038] Embodiment 1: as Figure 1~2 , a manipulator with a double-claw structure, including a fixing mechanism, a rotating mechanism and a double-claw mechanism;

[0039] The fixing mechanism is used to fix the manipulator on the machine; the rotating mechanism connects the fixing mechanism and the double air gripper mechanism;

[0040] The double air claw mechanism has two pneumatically controlled air claws.

[0041] The double air claw mechanism includes the first air claw and the second air claw connected with the air claw connecting block 62 and the air claw connecting block;

[0042] The first air claw includes the first air claw connecting plate 51, the first fixed splint 53, the first air claw movable block 54 and the first movable splint 58; the first fixed splint is fixed on the air claw connecting block; the first air claw is connected The plate is connected to the connecting block of the air claw, and can slide laterally relative to the connecting block of the air...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com