Production method of leek flower flounder

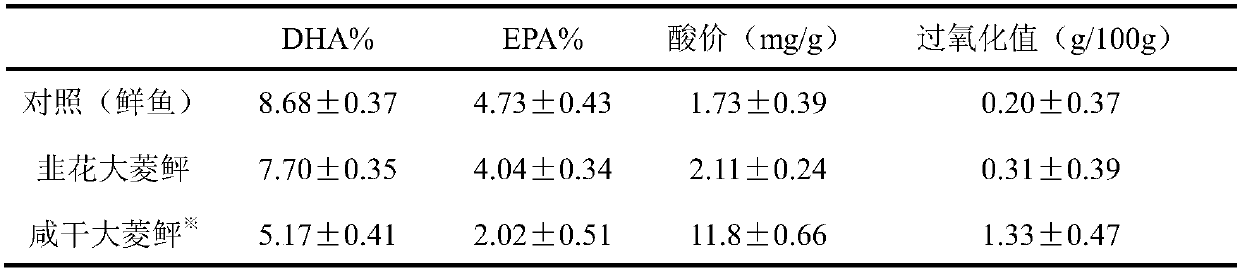

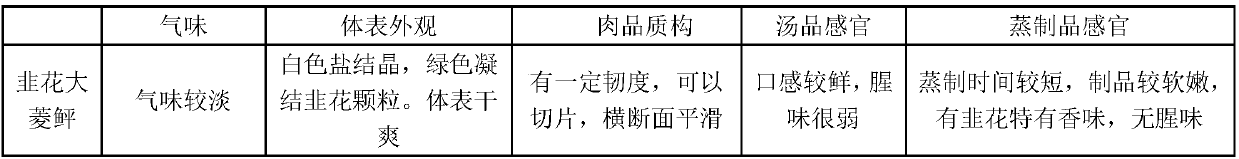

A production method and technology of chives, which are applied in the fields of preserving meat/fish with chemicals, preserving meat/fish with a protective layer, food science, etc., to achieve the effects of improving safety, delicious taste and unique flavor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Embodiment 1 Leek turbot

[0033] (1) Choose 3 live turbots with individual size of 300g~500g, clean the fish body and put it into a clean and smooth flat-bottomed tank, sprinkle 1% refined salt on the fish body mass, and continue to use it after the fish stop jumping. Turn or stir slowly with a wooden shovel to promote a large amount of mucus on the surface of the flounder. After 15 minutes, pick up the flounder and scrape off the mucus on the body surface, then remove the gills and internal organs. Store in a place exposed to direct sunlight and ventilation for later use; collect the mucus in the sink and freeze it in the refrigerator for later use;

[0034] (2) Preparation of leek marinade

[0035] Select the leek flowers with leek seeds on the flower clusters, wash the leek flowers and put them into a flat-bottomed square sieve, take them out when no water droplets are observed at the bottom when shaking the square sieve, put them in a chopping machine, mix 500g of...

Embodiment 2

[0044] Example 2: Chive flounder

[0045] The preparation method of Chinese chive flounder, its specific steps are as follows:

[0046] (1) Select 4 desert flounder with an individual size of 300g ~ 400g, wash the fish body and put it into a clean and smooth flat-bottomed water tank, sprinkle 1% refined salt on the fish body mass, and continue to use it after the fish stop jumping. Turn or stir slowly with a wooden shovel to promote a large amount of mucus on the surface of the flounder; after 20 minutes, pick up the flounder and scrape off the mucus on the body surface, remove the gills and viscera, clean and place it on a flat sieve, and place it in a dry place. Store in direct sunlight and ventilated place. After the mucus is collected in the sink, put it in the refrigerator and freeze it for later use;

[0047] (2) Preparation of leek marinade

[0048] Put the leek flowers into a flat-bottomed square sieve after cleaning, take out when no water drops are observed at the...

Embodiment 3

[0058] 1) Weigh raw materials

[0059] Prepare raw materials such as leek flower, flounder, leek, sharp pepper, bamboo leaf pepper and refined salt;

[0060] 2) Pretreatment of flounder and mucus collection

[0061] The flounder must be live, and it is more appropriate to choose individuals with a size of 300g to 500g. After cleaning the fish body, put it into a clean and smooth flat-bottomed tank, sprinkle 1% of the fish body weight in refined salt, and use a wooden shovel to turn or stir the fish body to promote The surface of the flounder produces a large amount of mucus. After 18 minutes, pick up the flounder and scrape off the mucus on the body surface, remove the gills and internal organs, clean and place it on a flat sieve, and put it in a ventilated place without direct sunlight for later use. After collection, freeze in the refrigerator for later use;

[0062] 3) Preparation of leek marinade

[0063] Put the leek flowers into a flat-bottomed square sieve after clea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com