Distillation apparatus

一种蒸馏装置、蒸馏塔的技术,应用在蒸馏分离、共沸蒸馏、分馏等方向,能够解决设备运行成本和设备成本增加等问题,达到延长寿命、降低运行成本、降低设备成本的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

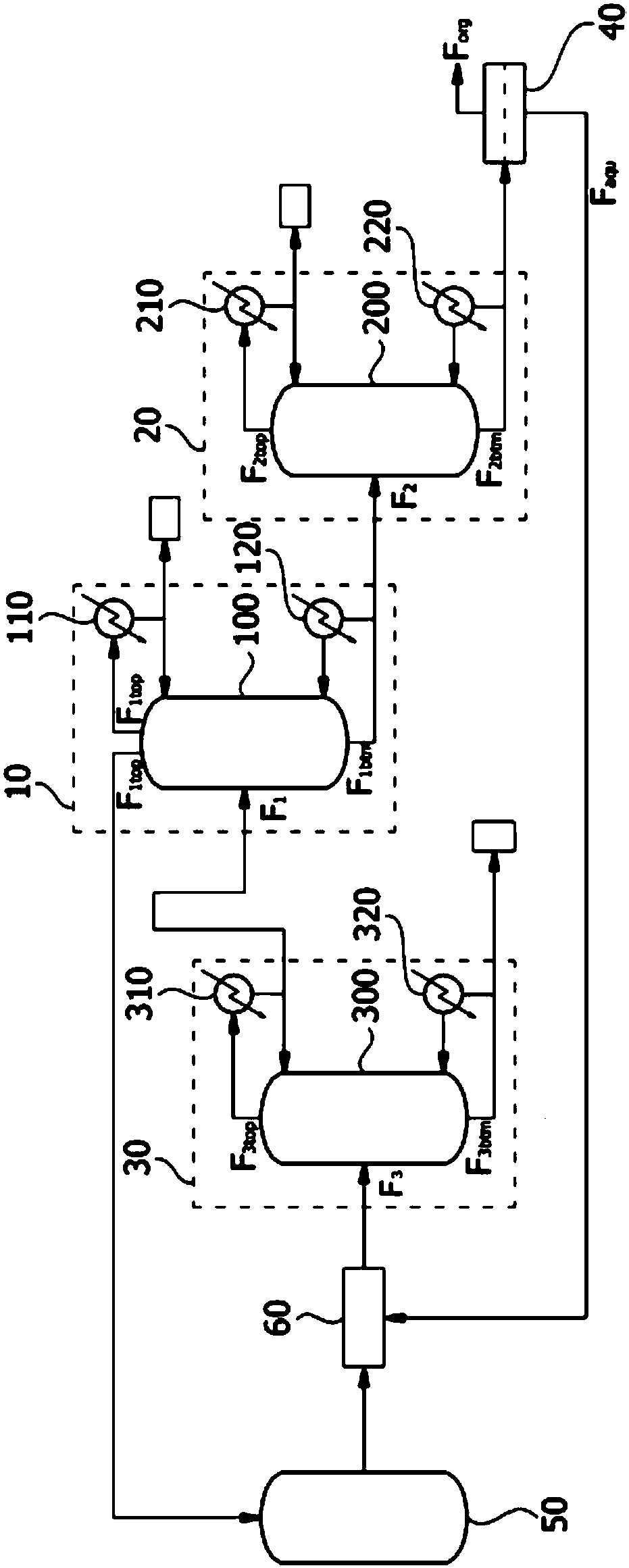

[0134] use Figure 8 The distillation unit separates acetone and methanol.

[0135] Specifically, a feedstock containing 55% by weight of acetone, 22% by weight of cumene, 4% by weight of α-methylstyrene, 0.03% by weight of methanol and 0.14% by weight of high-boiling components was heated at 88°C The temperature and the flow rate of 43,000kg / hr were introduced into the first distillation column with 65 theoretical stages.

[0136] The first top stream withdrawn from the top region of the first distillation column is passed through the first condenser and partly refluxed into the top region of the first distillation column. The remainder of the first overhead stream is separated and stored as a product comprising 99.8% by weight of acetone and 0.02% by weight of methanol, and the first bottom stream withdrawn from the bottom region of the first distillation column passes through a first reboiler, and A portion is refluxed to the bottom region of the first distillation column...

example 2

[0143] Acetone and methanol were separated by the same method as in Example 1 except that the operating conditions of the second distillation column were changed as shown in Table 1 below.

[0144] In the case of separating acetone and methanol using the distillation apparatus of Example 2, the amount of energy used in the first reboiler and the second reboiler and the removal rate of methanol are shown in Table 1 below.

example 3

[0146] use Figure 9 The distillation unit separates acetone and methanol.

[0147] Specifically, a feedstock containing 55% by weight of acetone, 22% by weight of cumene, 4% by weight of α-methylstyrene, 0.03% by weight of methanol and 0.14% by weight of high-boiling components was heated at 88°C The temperature and the flow rate of 43,000kg / hr were introduced into the first distillation column with 65 theoretical stages.

[0148] The first top stream withdrawn from the top region of the first distillation column is passed through the first condenser and partly refluxed into the top region of the first distillation column. The remainder of the first overhead stream is separated and stored as a product comprising 99.8% by weight of acetone and 0.02% by weight of methanol, and the first bottom stream withdrawn from the bottom region of the first distillation column passes through a first reboiler, and A portion is refluxed to the bottom region of the first distillation column...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com