High-power optical fiber laser

A fiber laser, high-power technology, applied in the direction of lasers, laser components, phonon exciters, etc., can solve problems such as Raman scattering, multi-mode oscillation, pump source chip interference, etc., to reduce nonlinear effects and improve life , to avoid the effect of mutual damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to understand the technical content of the present invention more clearly, the following examples are given in detail, the purpose of which is only to better understand the content of the present invention but not to limit the protection scope of the present invention.

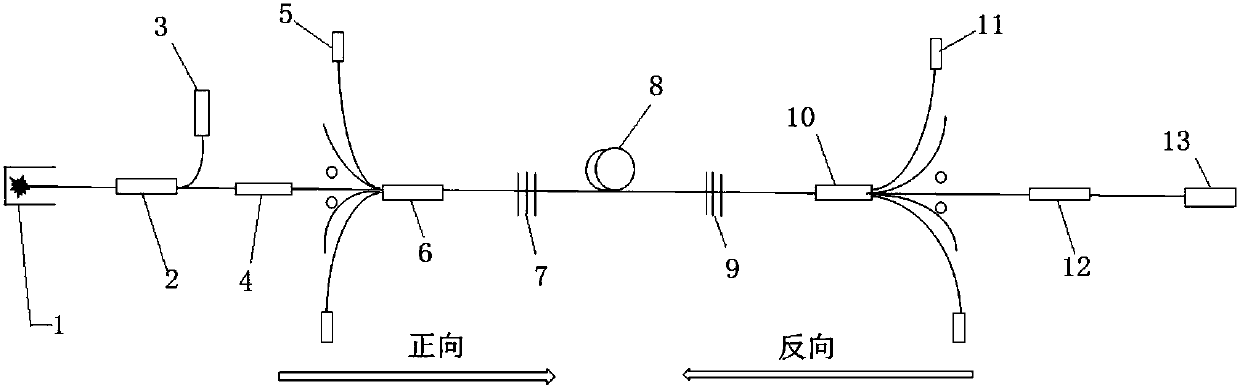

[0025] Such as figure 1 As shown, a high-power fiber laser, the cavity of the fiber laser includes a forward pump pump source module, a forward pump / signal combiner 6, a high reflection grating 7, a doped fiber 8, and a low reflection output grating 9 , a reverse pump / signal combiner 10 and a reverse pump pump source module; the doped fiber is a double-clad or triple-clad active fiber;

[0026] The forward pumping pump source module includes a plurality of forward pumping lasers 5, and the forward pumping lasers 5 provide pumping light to be transmitted to the forward pumping / signal beam combiner 6 through the confluence of pumping optical fibers of the forward pumping / signal beam combiner 6. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com