Multi-sector self-cleaning anti-corrosion and anti-blocking rotary air preheater

An air preheater, self-cleaning technology, applied in the direction of cleaning heat transfer devices, non-rotating equipment cleaning, lighting and heating equipment, etc. Strong and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

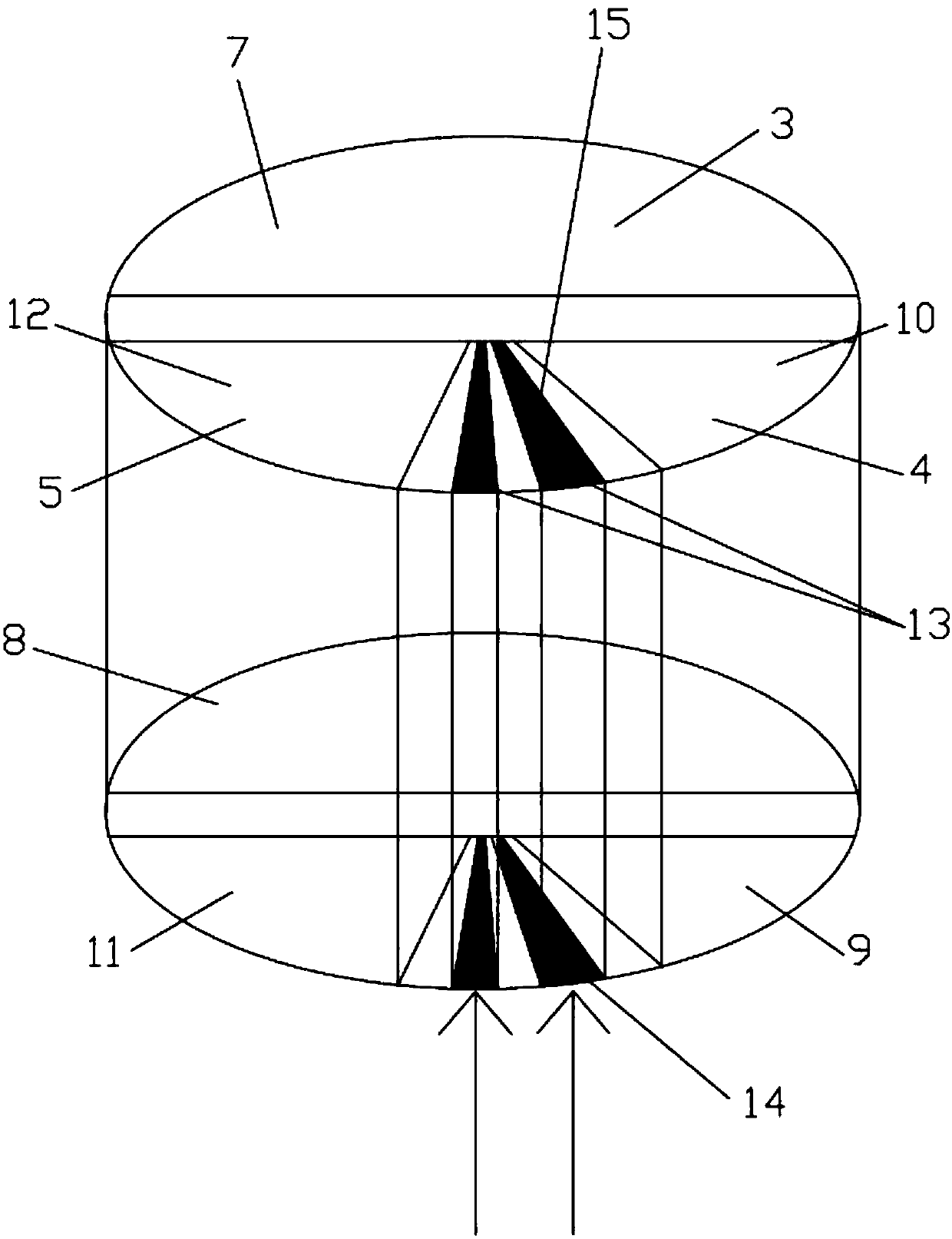

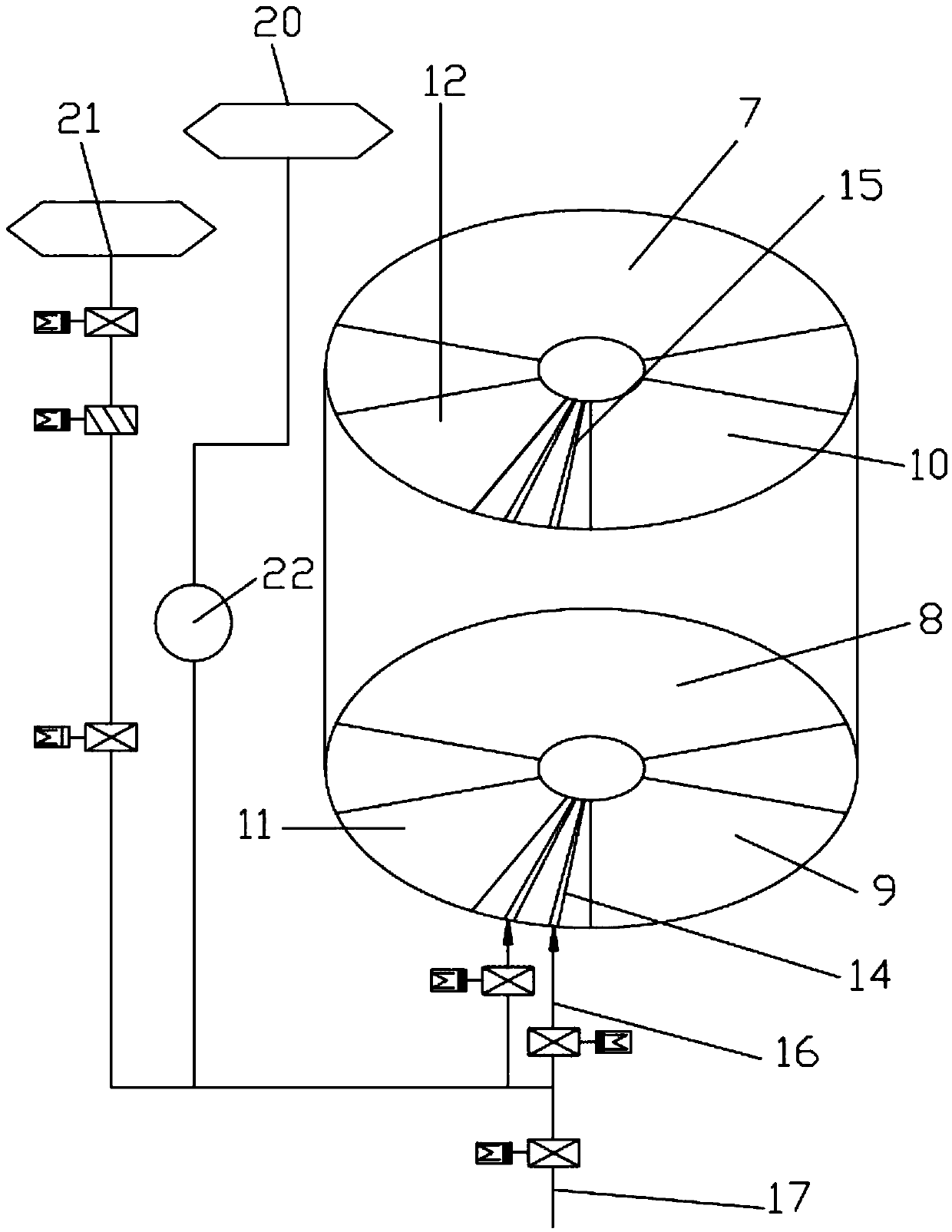

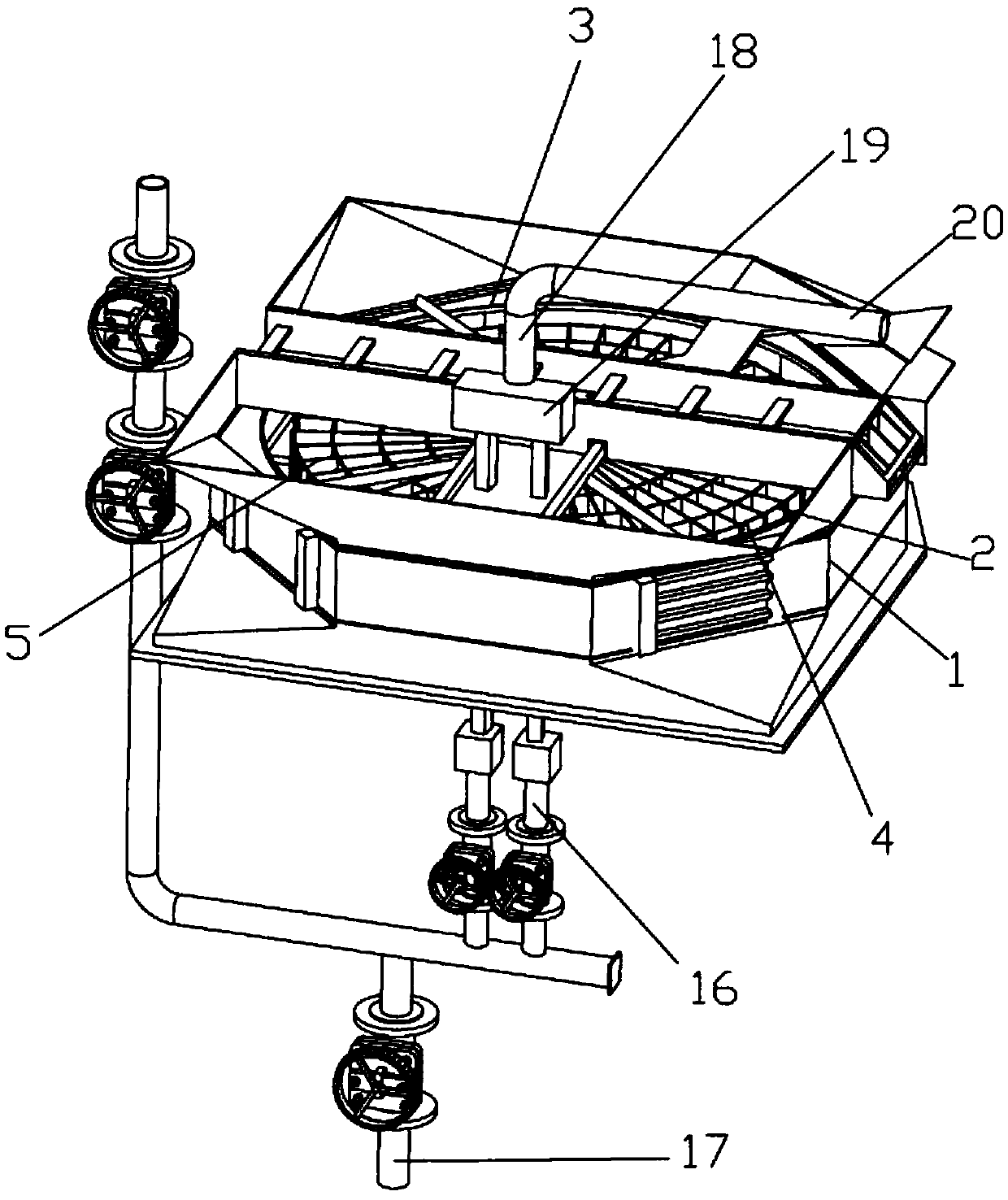

[0028] Such as Figure 1 to Figure 4 As shown, the multi-chamber self-cleaning, anti-corrosion, and anti-blocking rotary air preheater includes a shell 1, a central rotor 2 installed in the shell 1 and capable of rotating, a flue gas compartment 3 located inside the central rotor 2, and a central The primary air distribution bin 4 on the right side of the rotor 2 and the secondary air distribution bin 5 on the left side of the central rotor 2 .

[0029] The central rotor 2 is provided with a plurality of compartments 6 divided by partitions. The flue gas compartment 3, the primary air compartment 4 and the secondary air compartment 5 are all installed in the housing 1 and pass through the compartments. 6. There is a heat storage element inside the chamber 6. The central rotor 2 has a total of 48 chambers 6, each chamber 67.5°; the fan-shaped plate between the primary air and the flue gas, and the fan-shaped plate between the secondary air and the flue gas are all 25° (three-s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com