Pneumatic driving system of gas turbine

A gas turbine, pneumatic drive technology, applied in gas turbine installations, machines/engines, mechanical equipment, etc., can solve the problems of increasing lubricating oil demand and storage, generator overload, difficult to seal, etc., to achieve small temperature rise, high starting The effect of torque and emission without pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The gas turbine aerodynamic drive system involved in the invention will be described in detail below with reference to the accompanying drawings.

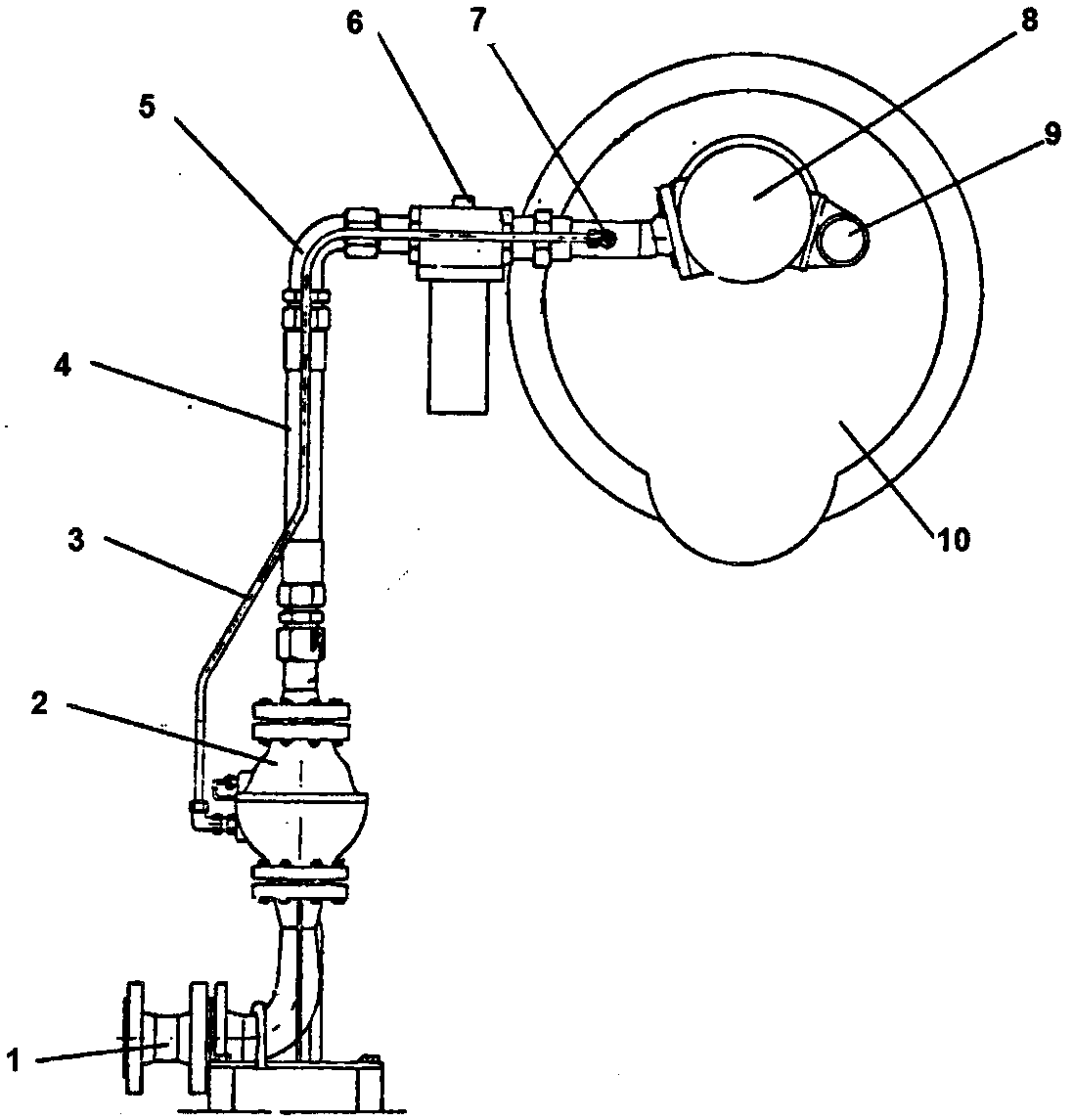

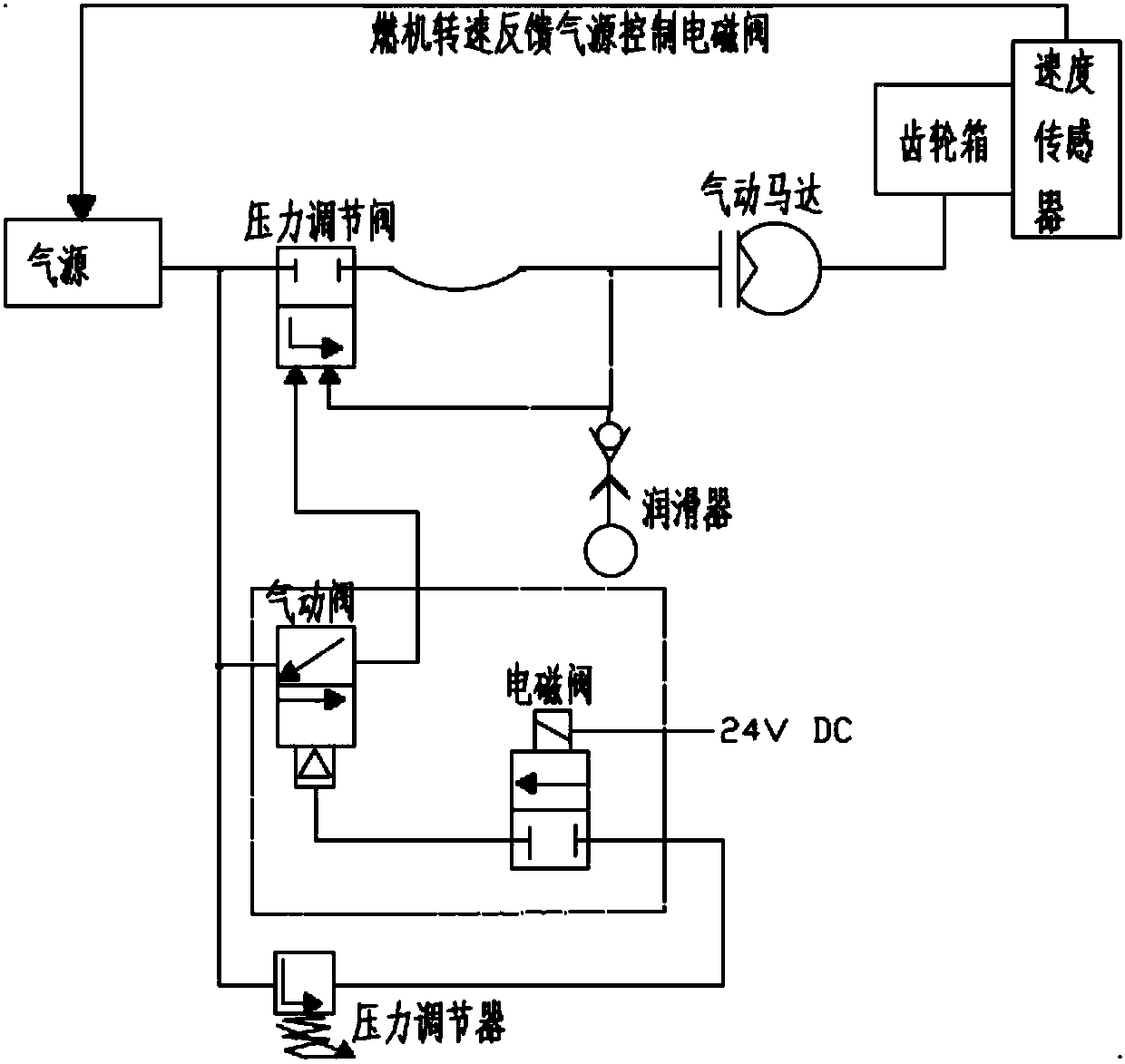

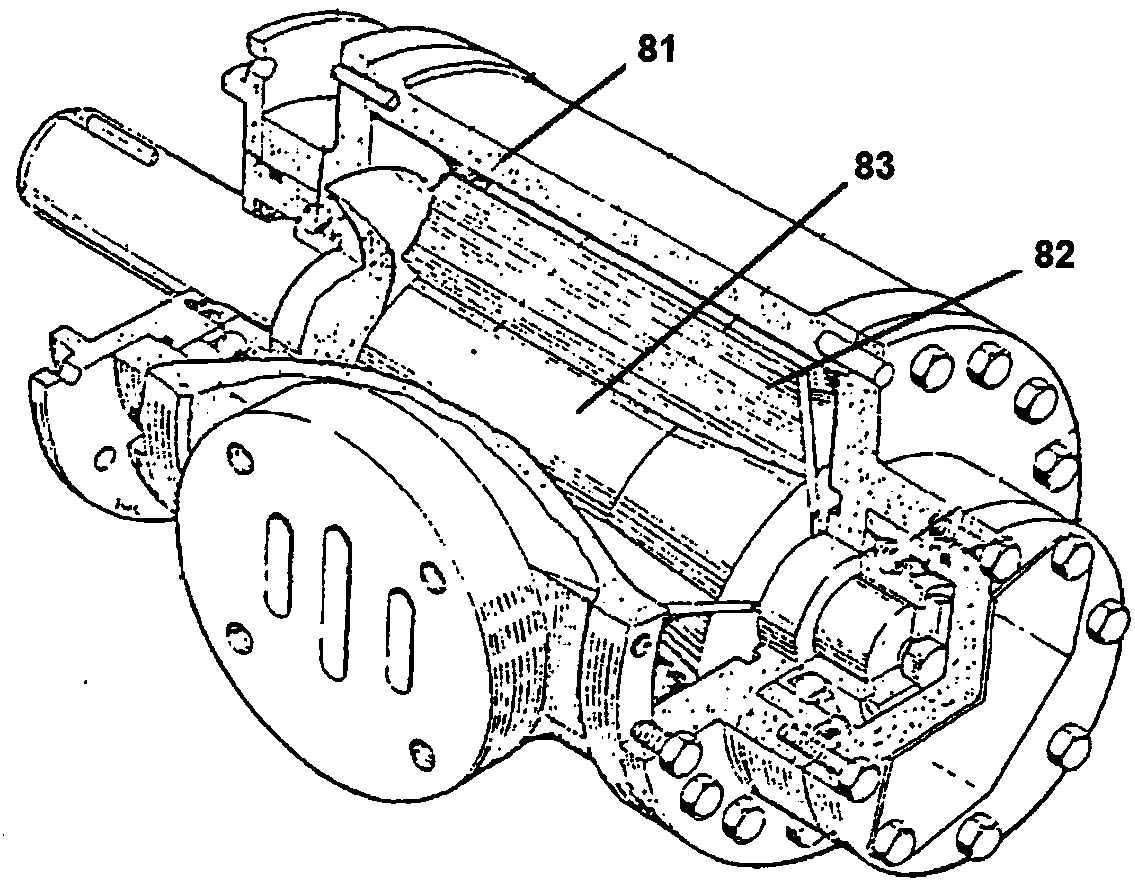

[0014] Such as figure 1 and 2 As shown, the air source is connected to the air source flange 1 on the pipe and bracket assembly to provide the working medium for the entire system. A flexible pipe 4 and an elbow 5 are optionally connected between the pressure regulating valve 2 and the lubricator assembly 6 on the pipe and bracket assembly. The end of the pipe and bracket assembly is connected to the air motor 8, and the output shaft of the air motor 8 is connected to the gearbox 10 of the gas turbine.

[0015] In order to facilitate installation and reduce the influence of steam turbine vibration on the gas source device, a section of flexible pipeline 4 can be arranged in the pipeline and bracket assembly.

[0016] In order to accurately adjust the outlet pressure, a pressure-taking pipe interface 7 is provided at the e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com