Anti-knock engine

An engine and cylinder technology, applied in the field of anti-knock engines, can solve problems such as increased thermal load and mechanical load, increased tendency of gasoline engine knock, cracking of cylinder head, etc., to strengthen the vortex in the cylinder to promote the formation of mixture gas and the flow of intake air The effect of large cross-section and reasonable structure design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in further detail below in conjunction with embodiment.

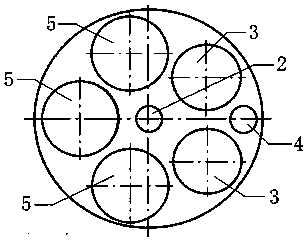

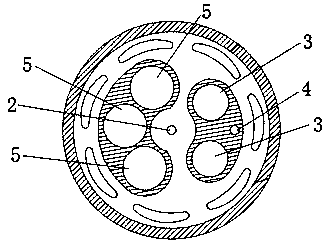

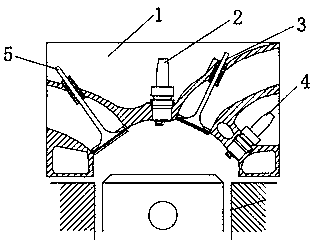

[0018] During specific implementation: if Figure 1 ~ Figure 3 As shown, a knock-proof engine, the cylinder head 1 has a combustion chamber corresponding to the cylinder on the cylinder block, the middle part of the combustion chamber is equipped with a first spark plug 2 facing the corresponding cylinder, It also includes a valve group arranged on the combustion chamber, the valve group includes two exhaust valves 3 and three intake valves 5 arranged adjacent to each other along the circumference of the corresponding cylinder, the intake valves 5 and exhaust valves 3 are arranged along the circumferential direction of the corresponding cylinder, and the two exhaust valves 3 and the three intake valves 5 are respectively located on both sides of the symmetrical central plane of the corresponding cylinder. A second spark plug 4 is further arranged between any two adjacent e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com