Multi-variety blended functional covering yarn and preparation process thereof

A core-spun yarn and functional technology, applied in the spinning field, can solve the problems of long-term aging, poor skin comfort, airtight and deodorant, etc., achieve good dimensional stability of the fabric, increase multi-functionality, anti-static and keep warm sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] A multi-variety blended functional core-spun yarn, the core-spun yarn uses PBT filament as the core yarn, and blended fibers are used as the outsourcing fiber of the core-spun yarn, and the blended fibers are viscose, ordinary acrylic fiber, tencel, goat The mixed fiber of velvet, the ratio of the raw materials of the PBT filament and the blended fiber is as follows: 25-29% of PBT filament, 38-42% of viscose fiber, 13-17% of ordinary acrylic fiber , 11-15% Tencel, 4-6% cashmere.

Embodiment 2

[0024] A multi-variety blended functional core-spun yarn, the specification of the PBT filament is 50D, and the ratio of the raw materials in the PBT filament and the blended fiber is as follows: 27% PBT filament, 40% % viscose fiber, 15% ordinary acrylic fiber, 13% tencel, 5% cashmere.

Embodiment 3

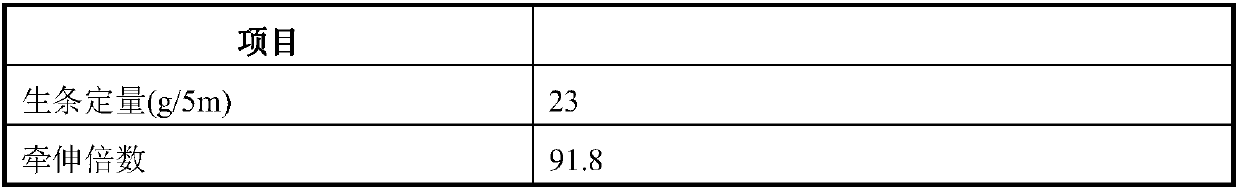

[0026] The production process of a kind of multi-variety blended functional core-spun yarn adopting the above-mentioned embodiment 2 comprises the following process steps:

[0027] Step 1, making the mixed fiber into roving, which includes the steps of blending, cleaning, carding, drawing, and roving;

[0028] Step 2, spinning process: use spinning frame, with PBT filament as core yarn, the roving that mixed fiber is made is as core-spun yarn, is made into core-spun yarn;

[0029] Step 3. Winding process: wind the manufactured core-spun yarn into a bobbin on a winder.

[0030] In the cotton blending process, after the raw materials in the blended fibers are evenly mixed according to the proportion, they are packed tightly and pressed into cotton bales, and the cotton bales are closely arranged and placed vertically; Squeeze for a certain period of time so that the water can evenly penetrate into the raw material, set the distance of the beater blade protruding from the rib to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com