Method for preparing colored polyimide fibers through two-step continuous production

A technology of colored polyimide fibers and colored polyimide fibers, which is applied in the field of two-step continuous production and preparation of colored polyimide fibers, can solve the problems of polyimide surface inertness, etc., and overcome the adsorption capacity Poor, strong adsorption capacity, low curing temperature effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

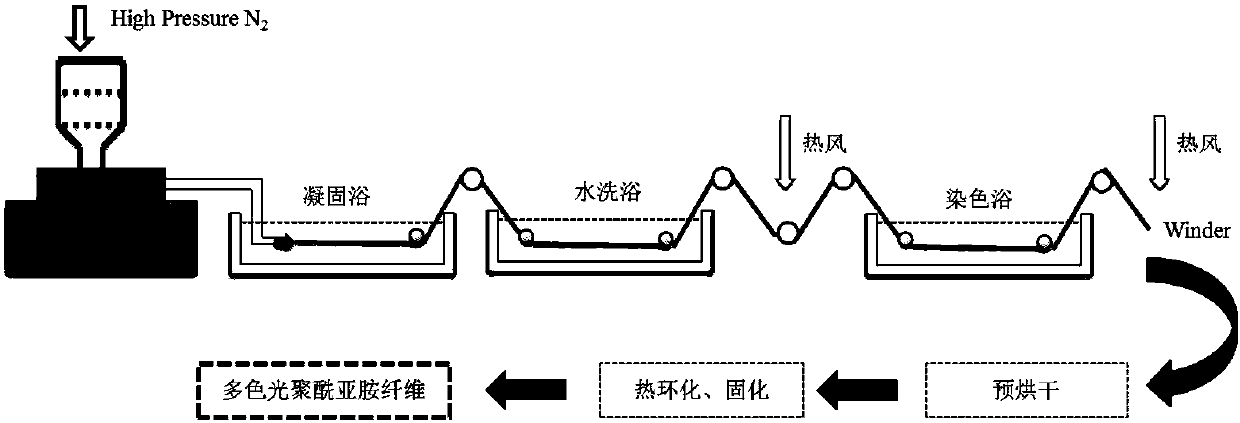

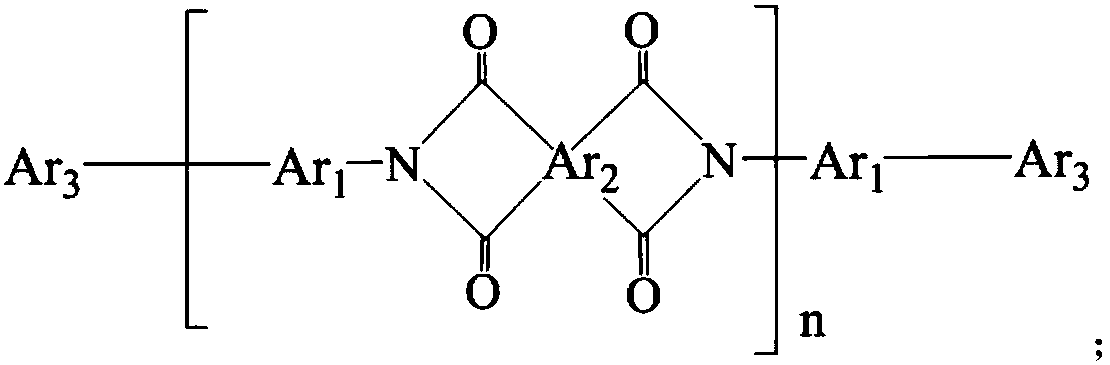

[0036] Using the "two-step method" dry-spraying and wet-spinning technology, a polyamic acid solution with a solid content of 15% phthalic anhydride / 4,4'-diaminodiphenyl ether structure (the solvent is DMAc) is used as the spinning dope, and after coagulation Bath molding, the coagulation bath is ethanol / water (1 / 1, v / v), washed with water, dried by hot air at 60°C, and dyed. The composition of the dyeing solution is: polyimide resin with a solid content of 5%.

[0037]

[0038] The pigment is phthalocyanine blue, accounting for 2% of the total mass of the solution, the solvent is tetrahydrofuran, and the temperature of the dyeing solution is 30°C; after dyeing, hot air drying is performed at a temperature of 80°C, and then pre-drying is performed at a temperature of 50°C for 6 hours. , cyclized at 110 ℃ for 1h, 280 ℃ cyclization for 1h to obtain blue polyimide fiber. The thermal decomposition temperature of the obtained blue polyimide fiber is higher than 490 ℃, and the th...

Embodiment 2

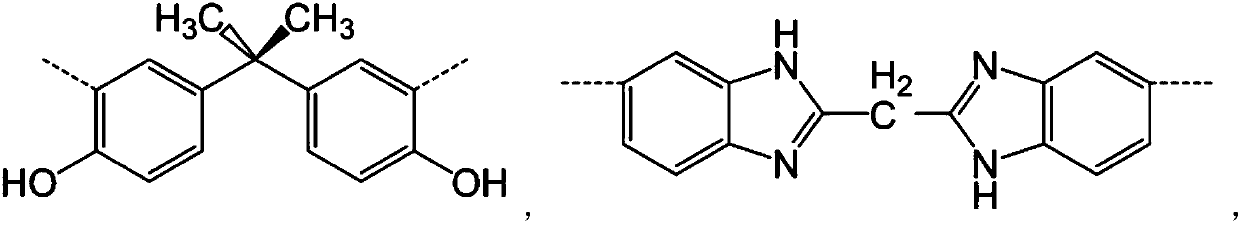

[0040] Using the "two-step method" dry-spraying and wet-spinning technology, a polyamic acid solution with a solid content of 13.5% biphenyl dianhydride / p-phenylenediamine structure (the solvent is DMAc) is used as the spinning stock solution, which is formed by a coagulation bath. It is DMAc / water (1 / 1, v / v), washed with water, dried with hot air at 70°C, and dyed. The composition of the dyeing solution is: polyimide resin with 3% solid content, and the structural formula is as follows:

[0041]

[0042] The pigment is Cosmetic Pink RC01 (Pigment Red 181), accounting for 1% of the total mass of the solution, the solvent is DMAc, and the temperature of the dyeing solution is 80 °C; after dyeing, hot air drying is performed at a temperature of 80 °C, and then the temperature is 50 °C. Pre-drying for 8h, cyclization at 110°C for 1h, and cyclization at 310°C for 1h to obtain orange polyimide fibers. The thermal decomposition temperature of the obtained orange polyimide fiber i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal decomposition temperature | aaaaa | aaaaa |

| thermal decomposition temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com