Automatic pressure stabilization and gas nitriding control method

A technology of gas nitriding and voltage stabilization, which is applied in the field of gas chemical heat treatment, can solve problems such as excess flow, potential safety hazards, and equipment overpressure, and achieve the effect of ensuring pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

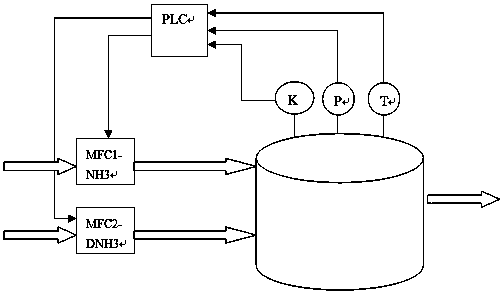

[0040] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0041] When the material of a certain alloy composition needs to be gas nitrided, according to the technical requirements, different nitrogen potential Kn values need to be applied in different process sections, such as switching from Kn=2 to Kn=1.

[0042] When the system is at Kn=2, NH3=3Nm3 / h, DNH3=1Nm3 / h, the furnace pressure is P1=1020mbar, the hydrogen probe measured and calculated Kn-real=2.0;

[0043] After a period of time, the Kn setting value is automatically switched to Kn=1. At this time, the actual Kn-real=2.0 in the system is far > 1. According to the PID parameters, it is calculated that DNH3 needs to be increased by 2Nm3 / h.

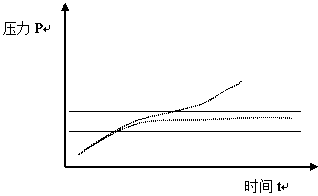

[0044] According to the traditional method, the total flow F=3+3=6Nm3 / h. It will increase by 50% compared with the original flow rate of 4Nm3 / h, and the furnace pressure will rise greatly in a short period of ti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com