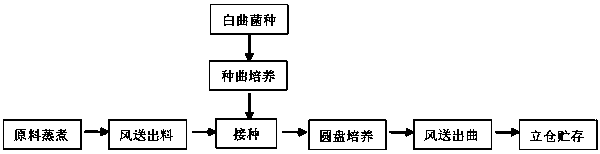

Production process of aspergillus candidus bran koji

A production process and technology of white koji bran, applied in the preparation of alcoholic beverages and other directions, can solve the problems of mechanization, low degree of automation, low degree of mechanization and automation, low production efficiency, etc., to improve the accuracy of process control, optimize equipment layout, The effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0067] a. Curtain seeding production

[0068] Ingredients: Take 90 parts of bran, 15 parts of rice husk, pour 85 parts of water into it, mix evenly, put it on a stainless steel flat plate and spread it flat, the koji material is 1cm thick, put the flat plate into the koji seeding machine, close Kind of koji machine, steam pressure 0.05MPa, sterilized for 60min.

[0069] Inoculation: After the sterilization, turn on the automatic control system, cool the koji material to 36°C, and insert 0.4 parts of Hanoi white koji strains through the inoculation port.

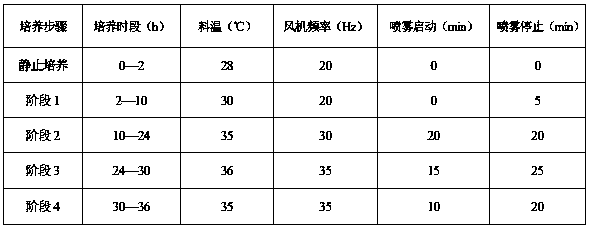

[0070] Cultivation: Set automatic cultivation parameters, divide into 5 periods, set parameters such as material temperature, spray time, fan frequency, etc., and turn on automatic cultivation, the cultivation time is 40h.

[0071] See the following table for automatic cultivation parameters at each stage:

[0072]

[0073] Drying: After the cultivation, the seed koji is prepared and dried to 13% moisture for later use. ...

Embodiment 2

[0083] a. Curtain seeding production

[0084] Ingredients: Take 95 parts of bran, 10 parts of rice husk, pour 90 parts of water into it, mix evenly, put it on a stainless steel flat plate and spread it flat. Turn off the koji machine, steam pressure 0.1MPa, and sterilize for 45 minutes.

[0085] Inoculation: After the sterilization, turn on the automatic control system, cool the koji material to 38°C, and insert 0.3 parts of Hanoi white koji strains through the inoculation port.

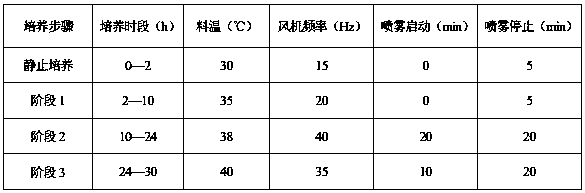

[0086] Cultivation: Set automatic cultivation parameters, divide into 6 periods, set parameters such as material temperature, spray time, fan frequency, etc., and turn on automatic cultivation, the cultivation time is 48h.

[0087] See the following table for automatic cultivation parameters at each stage:

[0088]

[0089] Drying: After the cultivation, the seed koji is prepared and dried to 14% moisture for later use.

[0090] b. Ventilated koji making

[0091] Ingredients: Take 900 parts of...

Embodiment 3

[0099] a. Curtain seeding production

[0100] Ingredients: Take 100 parts of bran, 13 parts of rice husk, pour 80 parts of water into it, mix evenly, put it on a stainless steel flat plate and spread it flat. Seed koji machine, steam pressure 0.1MPa, sterilize for 50min.

[0101] Inoculation: After the sterilization, turn on the automatic control system, cool the koji material to 37°C, and insert 0.4 parts of Hanoi white koji strains through the inoculation port.

[0102] Cultivation: Set automatic cultivation parameters, divide into 5 periods, set parameters such as material temperature, spray time, fan frequency, etc., and turn on automatic cultivation, the cultivation time is 40h.

[0103] See the following table for automatic cultivation parameters at each stage:

[0104]

[0105] Drying: After the cultivation, the seed koji is prepared and dried to 15% moisture for later use.

[0106] b. Ventilated koji making

[0107] Ingredients: Take 810 parts of bran and 82 par...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com