Straw-containing building material as well as preparation method and application thereof

A technology of building materials and straw, which is applied in the field of building materials containing straw and its preparation, can solve the problems of low utilization rate, environmental pollution, etc., achieve stable performance, improve air quality, and facilitate industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

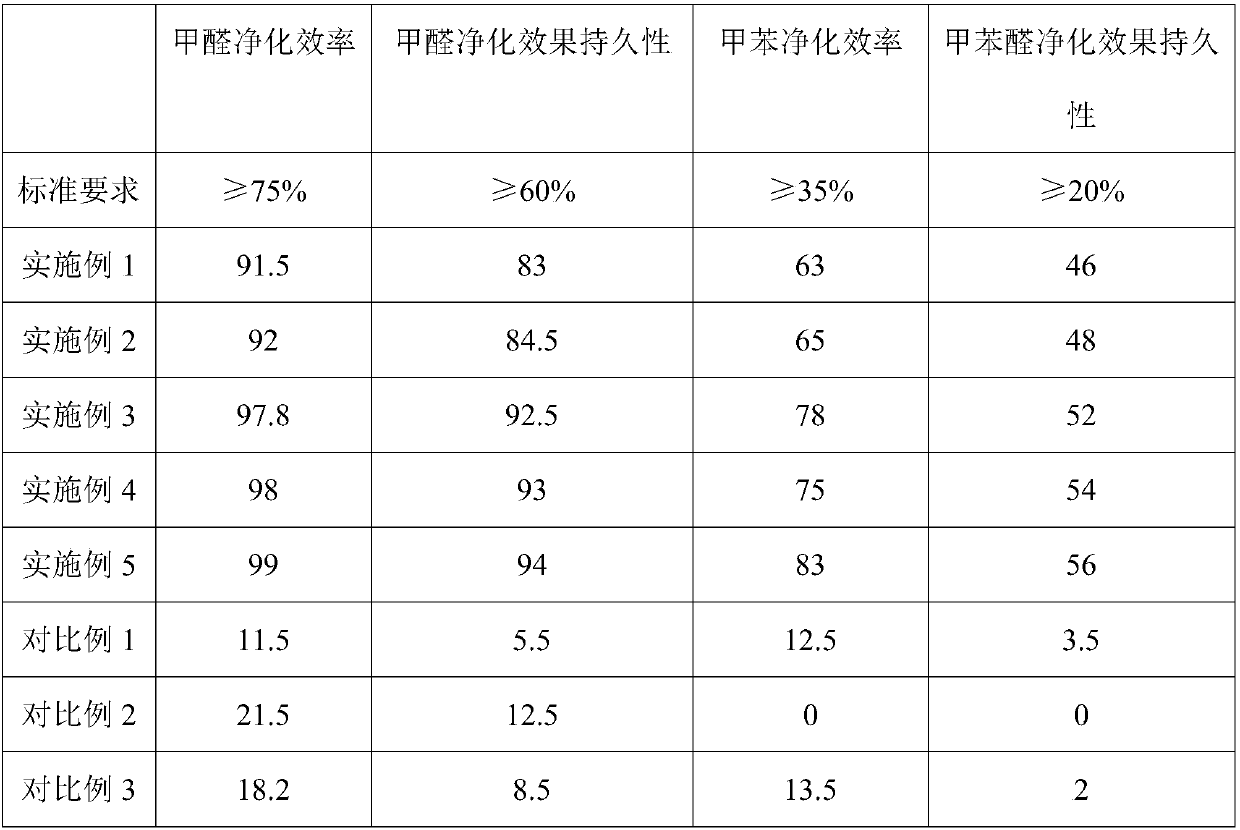

Examples

Embodiment 1

[0023] In the embodiment of the present invention, a building material containing straw includes the following raw materials: 28kg of straw, 15kg of talcum powder, 33kg of VAE emulsion, 3kg of bamboo vinegar, 11kg of potassium permanganate, and 5kg of manganese acetate.

[0024] Mix manganese acetate with 14 times its mass of deionized water to obtain a manganese acetate solution; mix potassium permanganate with 20 times its mass of deionized water to obtain a potassium permanganate solution; grind the straw into powder, pass 200 Mesh sieve to obtain straw powder, mix the straw powder with half the weight of potassium permanganate solution, heat to 88°C, and keep stirring at this temperature for 55min at a stirring speed of 120r / min, then ultrasonic treatment for 0.6h, ultrasonic treatment The power is 800W, the ultrasonic temperature is 85°C, and the supernatant is collected by centrifugation to obtain the mixed solution A. Add bamboo vinegar and manganese acetate solution to...

Embodiment 2

[0026] In the embodiment of the present invention, a building material containing straw includes the following raw materials: 36 kg of straw, 25 kg of talcum powder, 41 kg of VAE emulsion, 7 kg of bamboo vinegar, 19 kg of potassium permanganate, and 9 kg of manganese acetate.

[0027] Mix manganese acetate with 15 times its mass of deionized water to prepare a manganese acetate solution; mix potassium permanganate with 22 times its mass of deionized water to obtain a potassium permanganate solution; grind the straw into powder, pass 200 Mesh sieve to obtain straw powder, mix the straw powder with half the weight of potassium permanganate solution, heat to 90°C, and keep stirring at this temperature for 60min at a stirring speed of 150r / min, then ultrasonically treat for 0.6-0.8h , the ultrasonic power was 800W, the ultrasonic temperature was 88°C, and the supernatant was collected by centrifugation to obtain a mixed solution A. Add bamboo vinegar and manganese acetate solution...

Embodiment 3

[0029] In the embodiment of the present invention, a building material containing straw includes the following raw materials: 30 kg of straw, 18 kg of talcum powder, 35 kg of VAE emulsion, 4 kg of bamboo vinegar, 13 kg of potassium permanganate, and 6 kg of manganese acetate.

[0030] Mix manganese acetate with 15 times its mass of deionized water to obtain a manganese acetate solution; mix potassium permanganate with 21 times its mass of deionized water to obtain a potassium permanganate solution; grind the straw into powder, pass 200 Mesh sieve to obtain straw powder, mix the straw powder with half the weight of potassium permanganate solution, heat to 90°C, and keep stirring at this temperature for 60min at a stirring speed of 150r / min, then ultrasonic treatment for 0.7h, ultrasonic treatment The power is 800W, the ultrasonic temperature is 88°C, and the supernatant is collected by centrifugation to obtain the mixed solution A. Add bamboo vinegar and manganese acetate solut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com