Low-migration hydrophobic starch-based nano-composite film and preparation method thereof

A composite film and nano-composite technology, which is applied in the field of inhibiting plasticizer migration, can solve the serious problems of plasticizers, achieve the effect of small diffusion coefficient, lower diffusion coefficient, and slow down the migration of plasticizers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] A low-migration hydrophobic starch-based nanocomposite film, the preparation method of the composite film is as follows:

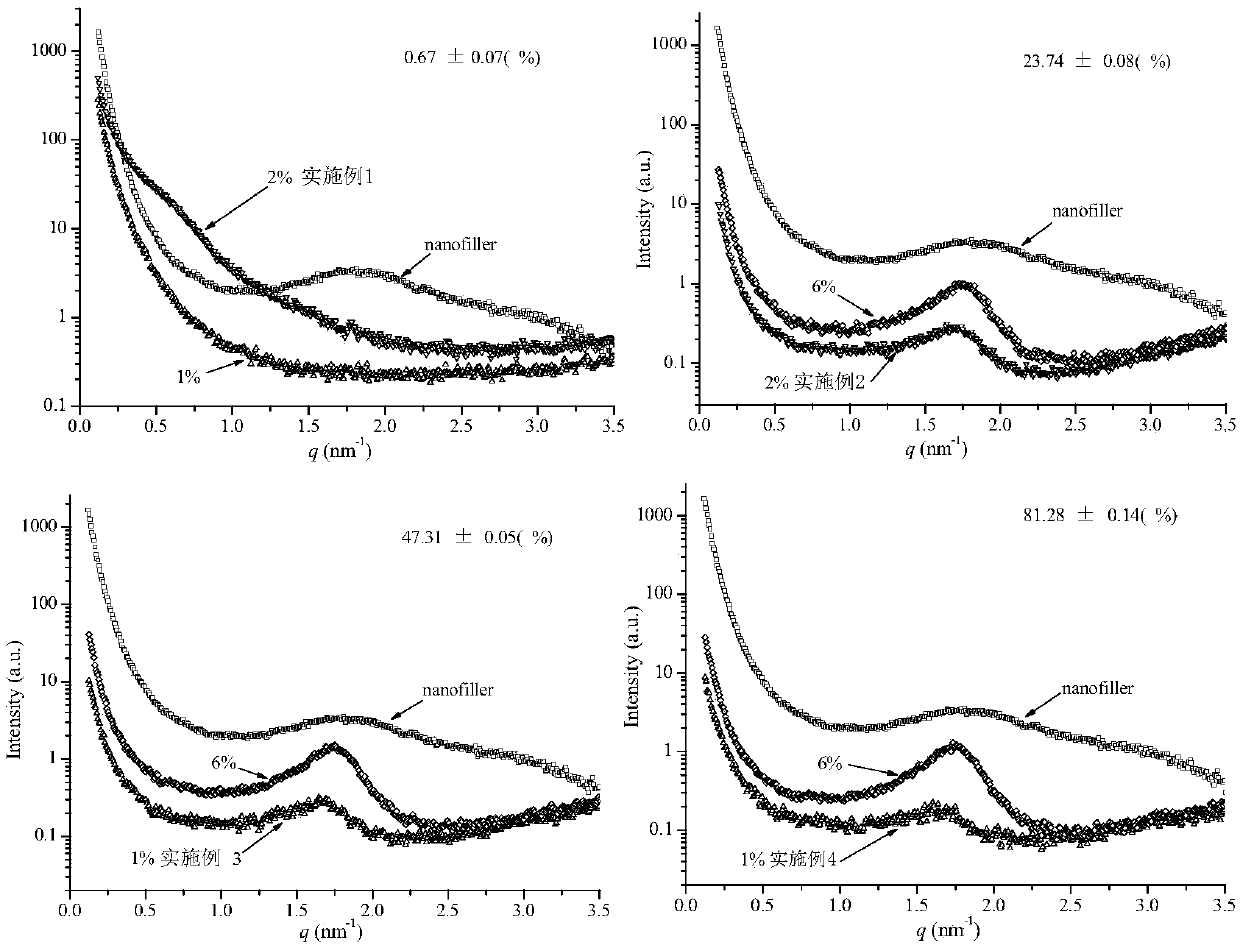

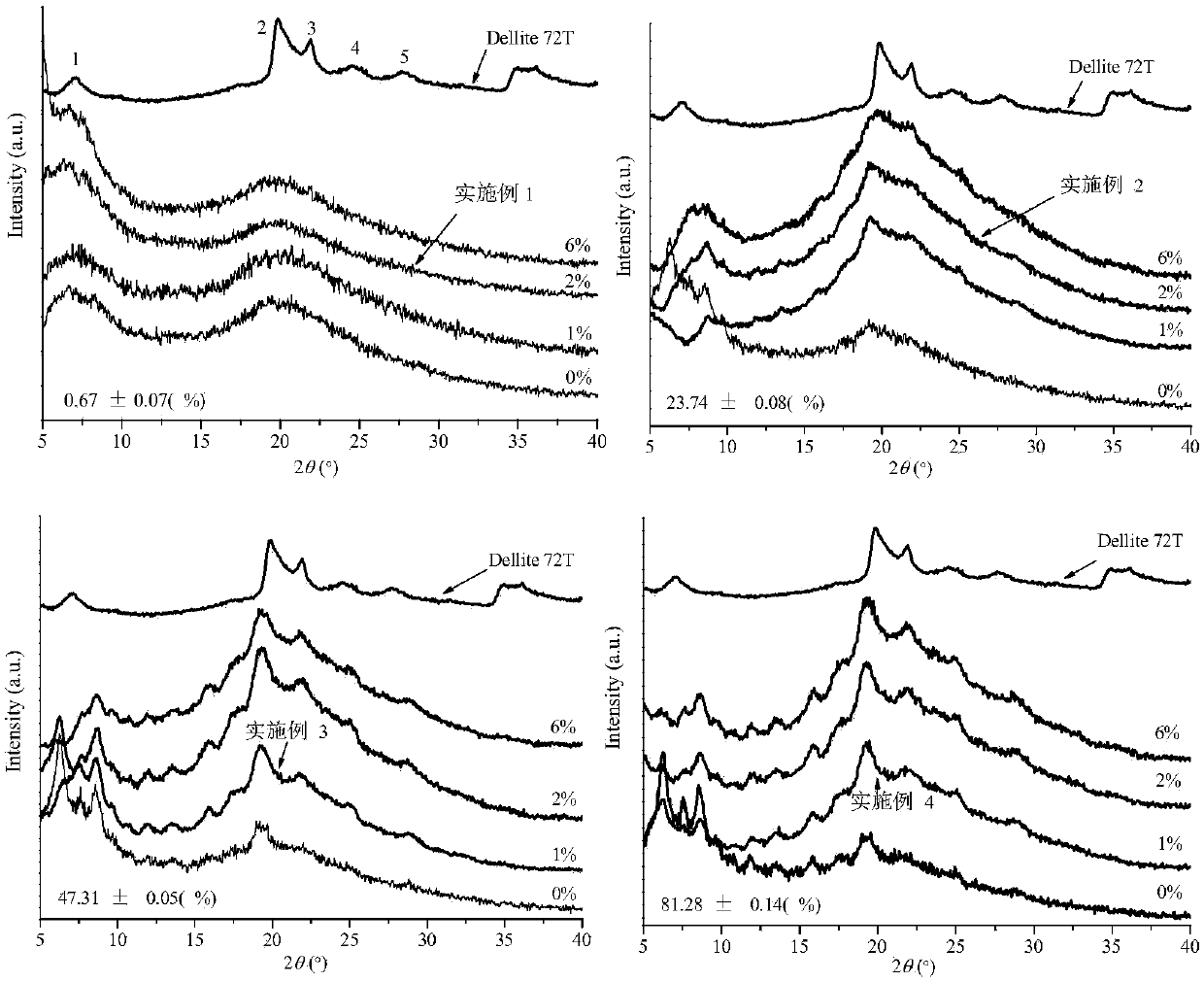

[0035] (1) Stir and activate corn starch (moisture content 12.65%) with an amylose content of 0.67 ± 0.07 (%) in pyridine at 85°C and a speed of 200r / min for 2 hours, according to the ratio of 1:5 to starch (g / mL) with propionic anhydride, stirred and reacted at 95°C and 300r / min for 4h, washed with water, dried and pulverized to obtain hydrophobic esterified starch with a high degree of substitution, with a degree of substitution of 2.61 ± 0.03.

[0036] (2) Make the hydrophobic starch obtained in step (1) into a solution according to the ratio of 4% by mass of acetone, stir and disperse, add organically modified montmorillonite Dellite 72T with 2% by mass of hydrophobic starch (w / w), to 30% (w / w) of the mass of hydrophobic starch was added with plasticizer triacetin, stirred for 4 hours, poured into a polypropylene mold, and dried at 45°C to obta...

Embodiment 2

[0038] A low-migration hydrophobic starch-based nanocomposite film, the preparation method of the composite film is as follows:

[0039](1) Stir and activate corn starch (moisture content 11.60%) with an amylose content of 23.74 ± 0.08 (%) in pyridine at 85°C and a speed of 200r / min for 2 hours, according to the ratio of 1:5 to starch (g / mL) with propionic anhydride, stirred and reacted at 95°C and 300r / min for 4h, washed with water, dried and pulverized to obtain hydrophobic esterified starch with a high degree of substitution, with a degree of substitution of 2.36 ± 0.01.

[0040] (2) The hydrophobic starch obtained in step (1) was formulated into a solution according to the proportion of 4% by mass of acetone, stirred and dispersed, and organically modified montmorillonite Dellite 72T with 2% by mass of hydrophobic starch (w / w) was added to 30% (w / w) of the mass of hydrophobic starch was added with plasticizer triacetin, stirred for 4 hours, poured into a polypropylene mol...

Embodiment 3

[0042] A low-migration hydrophobic starch-based nanocomposite film, the preparation method of the composite film is as follows:

[0043] (1) Stir and activate corn starch (moisture content 10.90%) with an amylose content of 47.31 ± 0.05 (%) in pyridine at 85°C and a speed of 200r / min for 2 hours, according to the ratio of 1:5 to starch (g / mL) with propionic anhydride, stirred and reacted at 95°C and 300r / min for 4h, washed with water, dried and pulverized to obtain hydrophobic esterified starch with a high degree of substitution, with a degree of substitution of 2.40 ± 0.01.

[0044] (2) The hydrophobic starch obtained in step (1) was formulated into a solution according to the proportion of 4% by mass of acetone, stirred and dispersed, and organically modified montmorillonite Dellite 72T with 1% by mass of hydrophobic starch (w / w) was added to 30% (w / w) of the mass of hydrophobic starch was added with plasticizer triacetin, stirred for 4 hours, poured into a polypropylene mo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of esterification | aaaaa | aaaaa |

| degree of esterification | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com