Membrane separation method and device for recycling ceftazidime mother liquor

A ceftazidime and membrane separation technology, applied in organic chemistry, reverse osmosis, etc., can solve the problems of large equipment damage, environmental pollution, increase the solubility of ceftazidime, etc., and achieve the effects of strong anti-pollution ability, saving labor costs, and easy cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

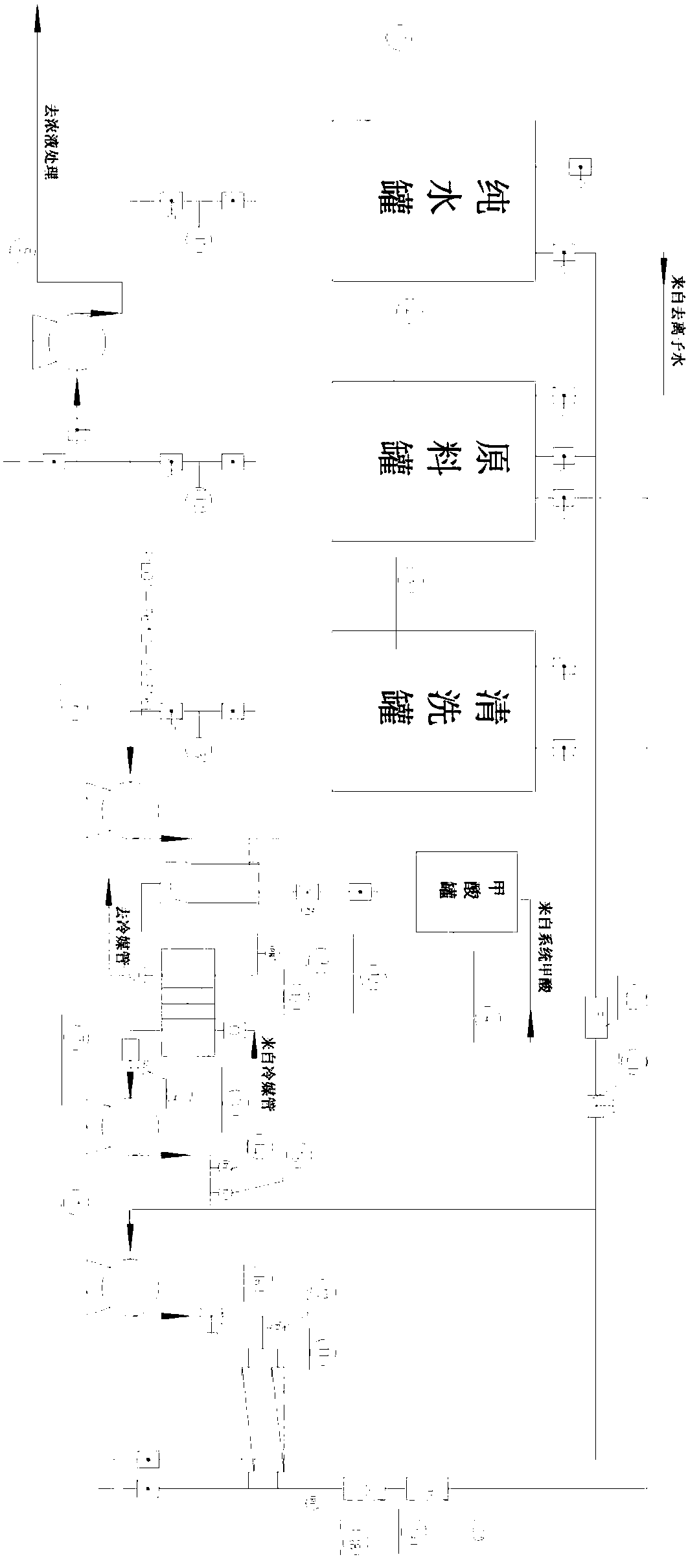

[0033] Embodiment 1: This embodiment illustrates the composition and connection relationship of the complete set of equipment from the desalination device of the ceftazidime mother liquor recovery method

[0034] A schematic diagram of the complete set of equipment is attached figure 1shown. Specifically, the equipment includes a modular pure water tank (1), a raw material tank device (2), a cleaning tank (3), a formic acid tank (4), a discharge pump (5), a feed pump (6), and a high-pressure pump (7), circulating pump (8), security filter (9), heat exchanger (10), nanofiltration membrane and membrane module (11), connecting pipeline and automatic control system.

[0035] Among them, the pure water tank (1), the raw material tank device (2), the discharge port of the cleaning tank (3) is connected with the discharge pump (5), the feed pump (6), and the feed pump (6) is connected with the security filter (9) Unicom; the formic acid tank (4) is connected with the security filte...

Embodiment 2

[0038] Embodiment 2: This embodiment illustrates the process of reclaiming ceftazime from ceftazime mother liquor after desalination

[0039] Cool the water in the reaction kettle to 0-5°C, add ceftazidime hydrochloride, and dissolve. Add sodium hydroxide dropwise, adjust the pH to 5.5-5.6, and filter to the crystallization tank. Maintain the temperature of the feed solution at 0-5°C, slowly adjust the pH to 4.3-4.4 with formic acid, crystallize, stop dropping, continue to add formic acid after growing the crystal for 2 hours, adjust the pH to 3.6-3.7, stop dropping, and grow the crystal again 4 hours. Solid-liquid separation, mother liquor collection into tank (2), the crystallization yield of ceftazidime at this moment is 87%. The crystallization mother liquor in the tank (2) is adjusted to pH 4.8-5.0 with sodium hydroxide solution earlier. The mother liquor is desalinated using membrane separation technology. In the desalination treatment, the pH of the mother liquor is ...

Embodiment 3

[0040] Embodiment 3: this embodiment illustrates the situation of implementing the process of the present invention in the equipment of embodiment

[0041] Take 50kg of ceftazidime hydrochloride and dissolve it in 800L stainless steel reaction kettle with 500L pure water, cool down to 0-5°C with refrigerant, stir at 80 rpm, and add dropwise 5N sodium hydroxide solution to adjust the pH of the solution to 5.5- 5.6, then filter, return the filtrate to the crystallization tank, maintain the temperature of the feed liquid at 0-5°C, slowly adjust the pH to 4.3-4.4 with formic acid, crystallize, stop dropping, continue to add formic acid after growing the crystal for 2 hours, adjust After the pH reaches 3.6-3.7, stop the dropwise addition, and grow the crystal for another 4 hours. Solid-liquid separation, the mother liquor is collected and poured into the raw material tank (2) of the desalination device, and the crystallization mother liquor in the tank (2) is first adjusted to pH 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com