Automatic sequencing device for cut-off valves

An automatic sorting and shut-off valve technology, applied in the direction of transportation and packaging, conveyors, conveyor objects, etc., can solve the problems of reducing the efficiency of automated production, easy to be entangled or stuck in a certain position, etc., to improve operating efficiency, The effect of ensuring stability and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

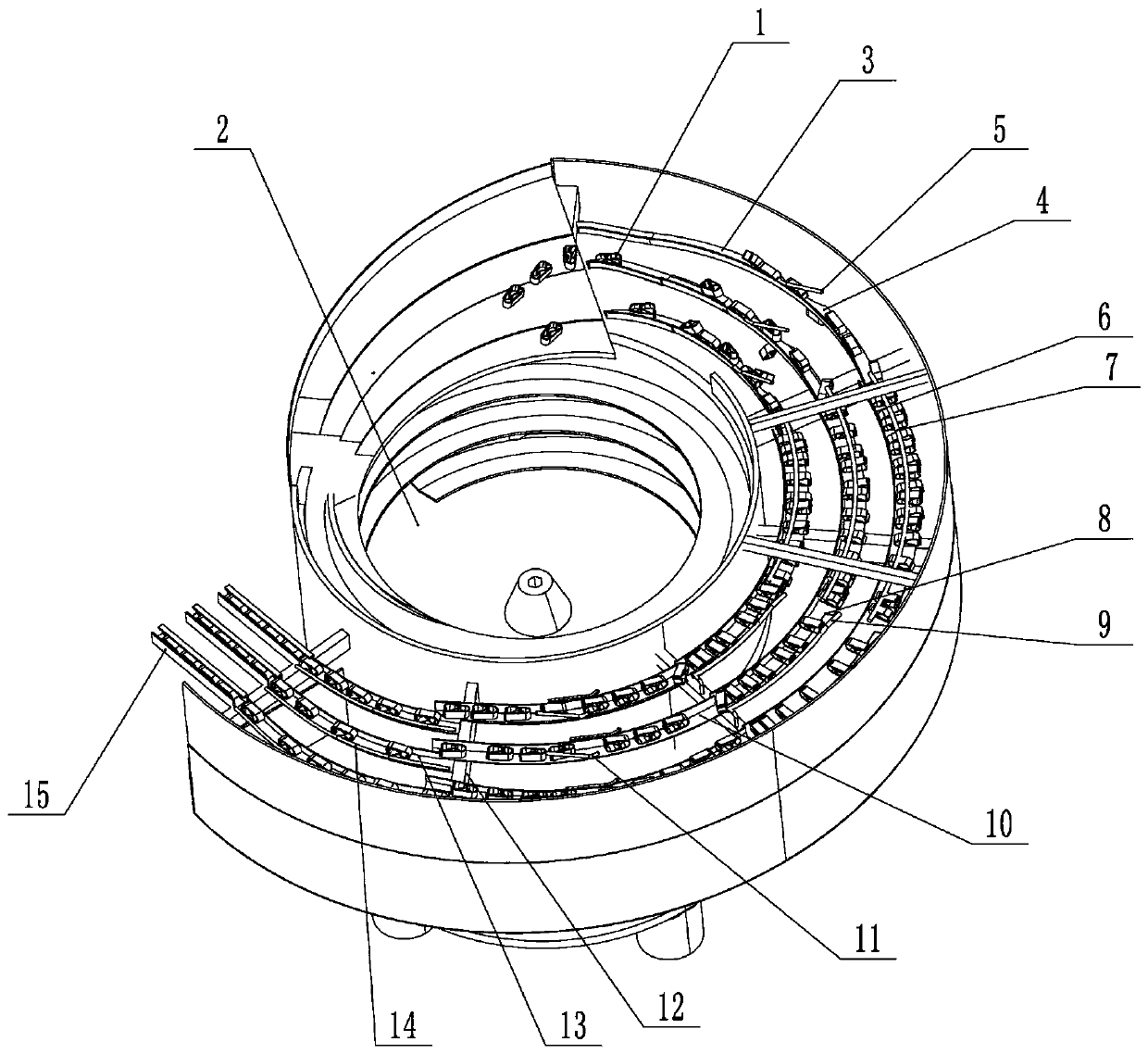

[0014] For better understanding and implementation, the present invention will be further described below in conjunction with accompanying drawing: Figure 1-4 As shown, the shut-off valve automatic sorting device mainly includes a shut-off valve 1, a vibrating plate 2, a slideway 3, a material passage 4, a pre-determined material passage 6 and an overturning material passage 10. The cut-off valve 1 is shaped like an elliptical special-shaped plastic part. One side of the cut-off valve 1 is an open S-shape, and one end of the S-shape is large and the other end is small. The slideway 3 , the feeding channel 4 , the preliminary setting channel 6 and the turning channel 10 are all made of bent L-shaped stainless steel. The shut-off valve automatic sorting device is erected on the vibrating plate 2 as a whole. The vibrating plate 2 is used as the power source for the movement of the shut-off valve 1. There is a spiral feeding channel inside, which is a spiral structure. Three grou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com