Multidirectional die forging production line

A multi-directional die forging and production line technology, applied in the field of forging, can solve the problems of low production efficiency, inability to realize continuous production of multi-type forgings, and unsuitability for the production of multi-directional die forgings of various specifications and models, so as to achieve high production efficiency and realize Unattended automatic control, setting tight effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the examples, the purpose is only to better understand the contents of the present invention, therefore, the examples given do not limit the protection scope of the present invention.

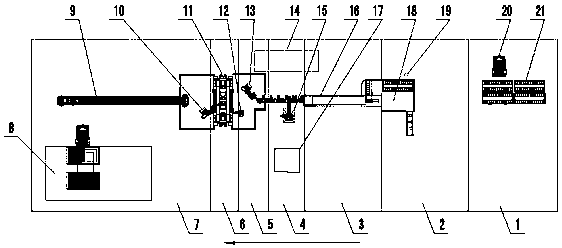

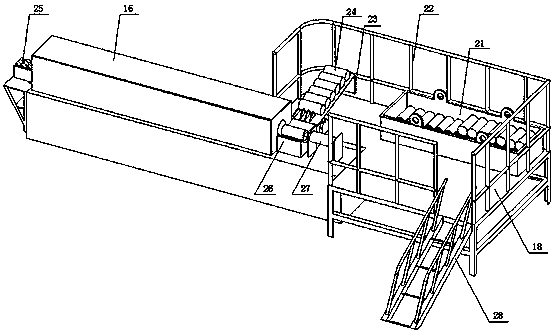

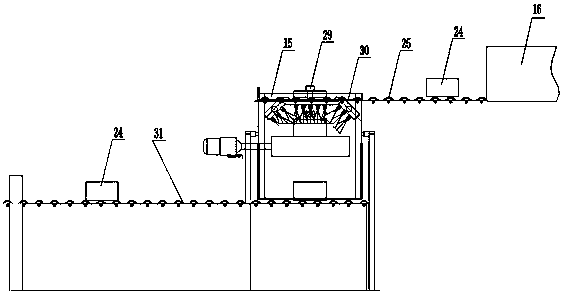

[0025] see figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , a multi-directional die forging production line, including raw material unloading workers arranged in sequence, 1, billet loading station 2, induction heating station 3, water descaling station 4, spraying lubrication station 5, forging station 6 , Forging transfer station 7.

[0026] The raw material blanking station 1 is provided with a sawing device 20 and a storage frame 21 for holding the sawed blank 24. The raw material blanking station 1 is mainly used for forging blanking, and the sawing device 20 is configured to complete After the processing of the round bar is completed, the round bar is placed in the designated storage...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com