Formula of pigskin jelly sausage and processing method thereof

A technology of pigskin jelly and sausage, which is applied in the field of food processing, and can solve problems such as affecting the taste, not being able to store for a long time, and not being able to cut sausages to eat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

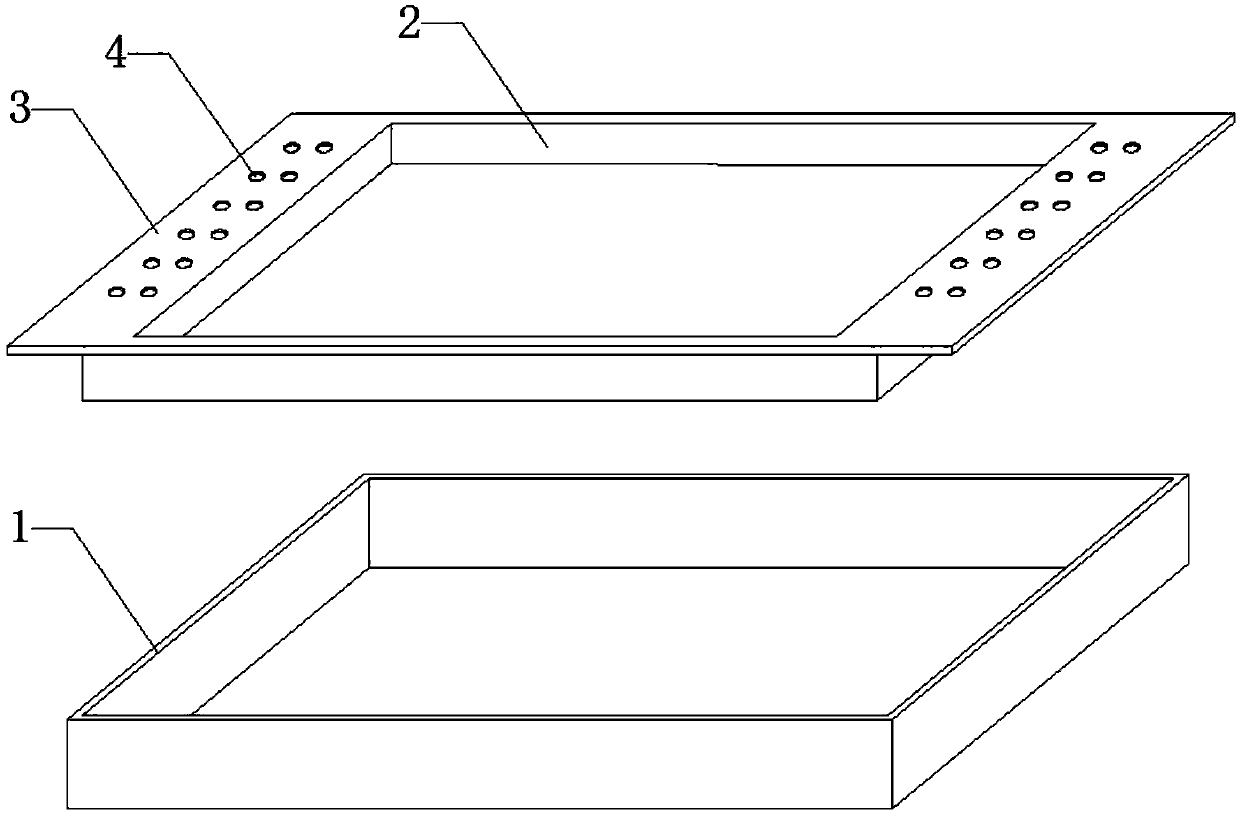

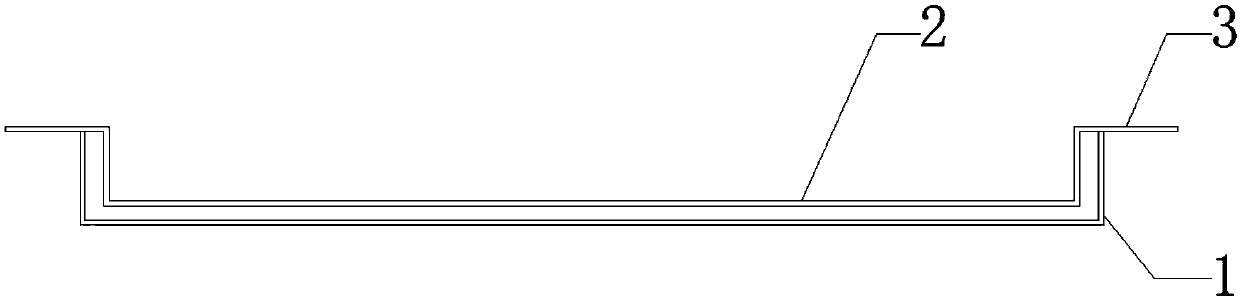

Image

Examples

Embodiment 1

[0024] A recipe and processing method of pigskin frozen sausage, comprising the following parts by weight: 30 parts of pigskin, 5 parts of edible gelatin, 8 parts of konjac gum, 4 parts of rice starch, 6 parts of soybean protein, 2 parts of potato starch, and 2 parts of spices parts, casings, saline, baking soda solution.

[0025] Preferably, the spices include star anise, prickly ash, cinnamon, angelica dahurica, mulberry leaves and hawthorn.

[0026] Preferably, the casing is pig small intestine or sheep small intestine.

[0027] Preferably, the saline is 4-5% sodium chloride solution, and the baking soda solution is 5% sodium bicarbonate solution.

[0028] Preferably, its processing method of described pigskin frozen sausage comprises the following steps:

[0029] S1. Select fresh pigskin with moderate thickness, wash and depilate, remove the subcutaneous fat with a knife, and soak in salt water for 2 hours;

[0030] S2. Boil the water, add pigskin and spices and cook fo...

Embodiment 2

[0037] A recipe and processing method of pigskin frozen sausage, comprising the following parts by weight: 35 parts of pigskin, 7 parts of edible gelatin, 12 parts of konjac gum, 6 parts of rice starch, 8 parts of soybean protein, 5 parts of potato starch, and 3 parts of spices parts, casings, saline, baking soda solution.

[0038] Preferably, the spices include star anise, prickly ash, cinnamon, angelica dahurica, mulberry leaves and hawthorn.

[0039] Preferably, the casing is pig small intestine or sheep small intestine.

[0040] Preferably, the saline is 5% sodium chloride solution, and the baking soda solution is 8% sodium bicarbonate solution.

[0041] Preferably, its processing method of described pigskin frozen sausage comprises the following steps:

[0042] S1. Select fresh pigskin with a moderate thickness, wash and depilate, remove the subcutaneous fat with a knife, and soak in salt water for 3 hours;

[0043] S2. Boil the water, add pigskin and spices and cook f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com