Building skin and method for erecting a building skin

A technology for buildings and coverings, applied in building structures, buildings, roofs using flat/curved panels, etc., can solve problems such as inability to follow assembly quality, and achieve the effect of eliminating fault sources and reducing manufacturing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

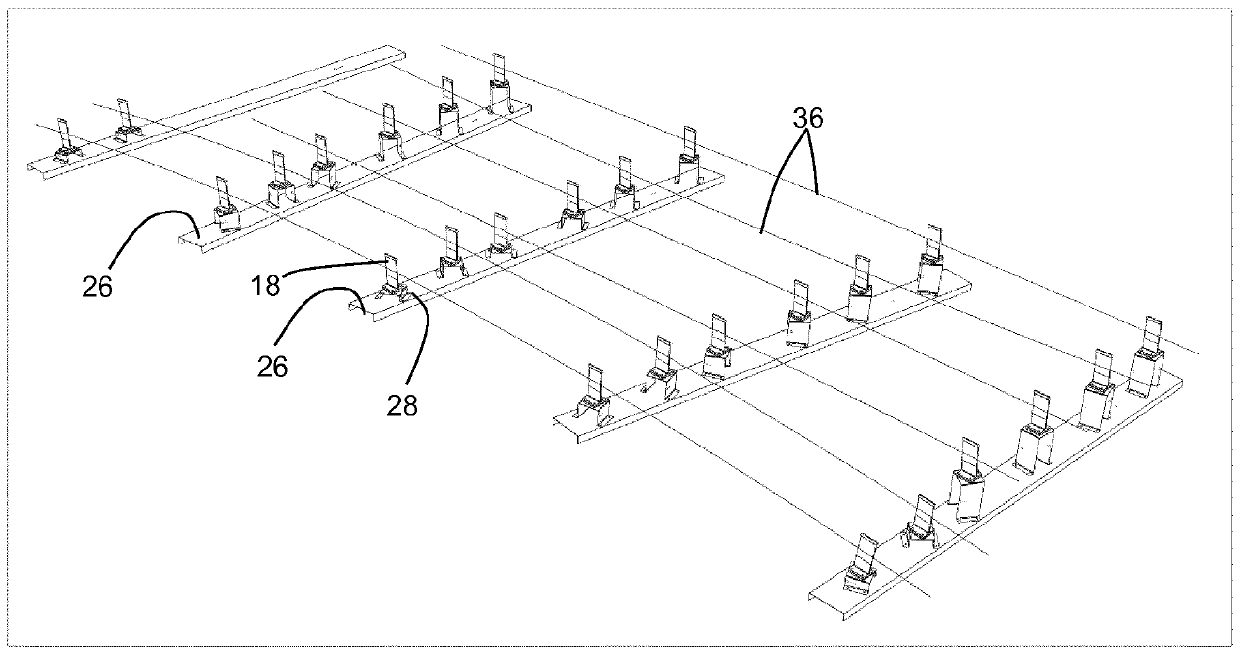

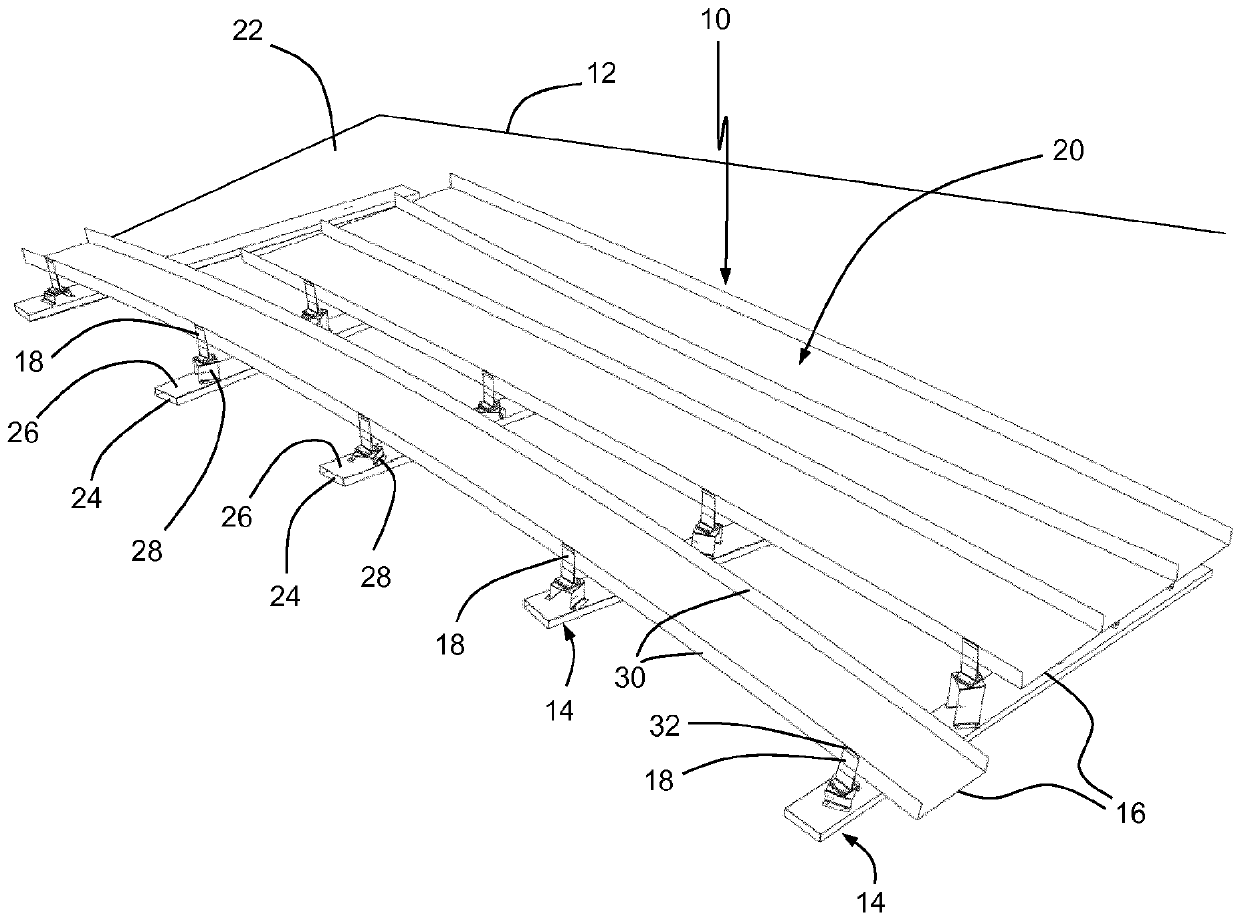

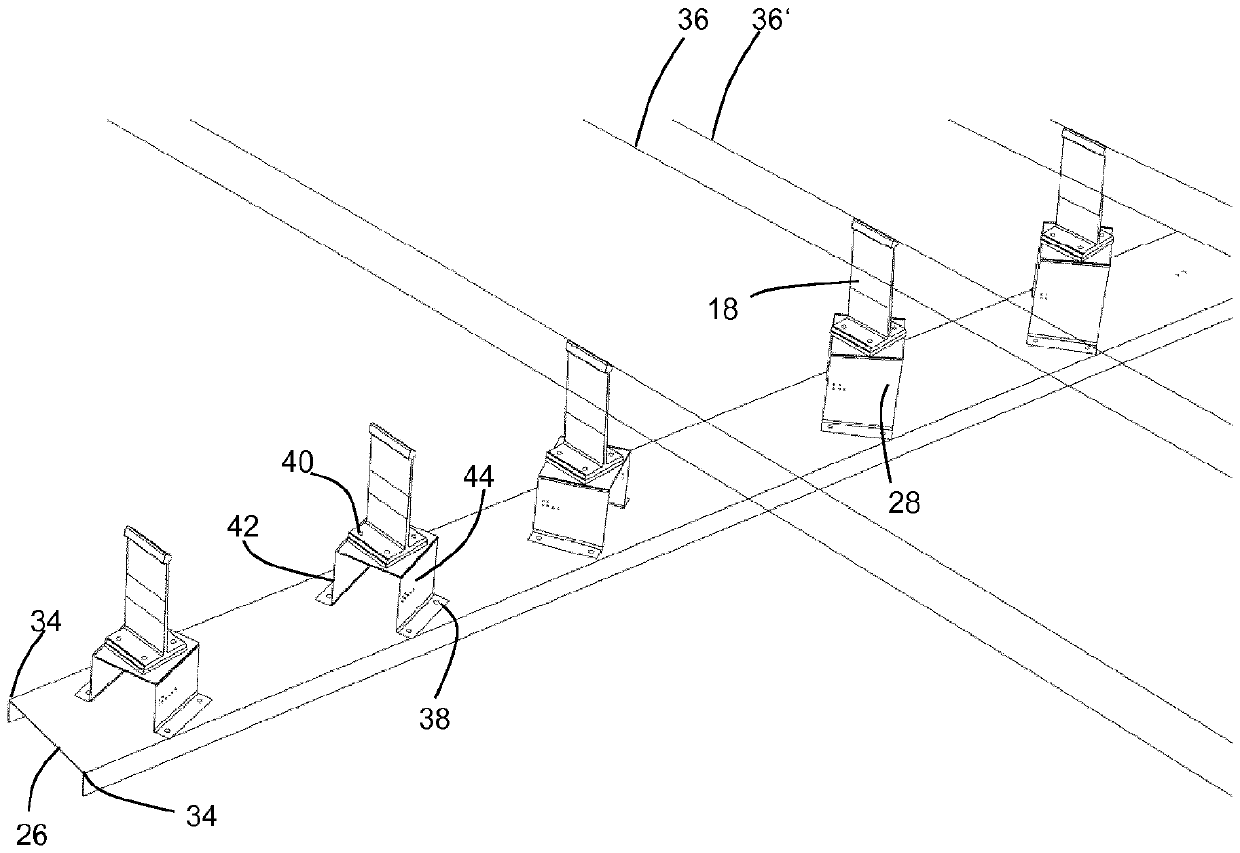

[0025] exist figure 1 The standing seam roof 10 shown in includes a support structure 14 mounted on a building 12 and a standing seam profile rail 16 composed of differently curved standing seam rails 16 supported at several points on the supports via standing seam brackets 18. The structural covering or roof covering 20 , which corresponds to a defined standing seam arrangement, expands the spatially curved surface as a so-called free-form surface.

[0026] The supporting structure 14 is supported on a bearing shell 22 of the building 12 , which has a simpler contour than the free-form surface of the roof covering 20 . The support structure 14 achieves contour or distance adaptation of this support and possibly creates gaps for thermal insulation structures (not shown). Expediently, the support structure 14 comprises a plurality of lower U-shaped support rails 24 distributed on the support shell 22, which are connected to upper U-shaped support rails 26 in the case of formin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com