Method for manufacturing circuit board

A manufacturing method and circuit board technology, which are applied in the direction of printed circuit manufacturing, printed circuit, and electrical connection formation of printed components, etc., can solve the problem of uneven desmear removal effect, poor desmear removal effect, and poor contact area of potassium permanganate And so on, to achieve the effect of uniform desmear removal, good desmear effect and sufficient desmear effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

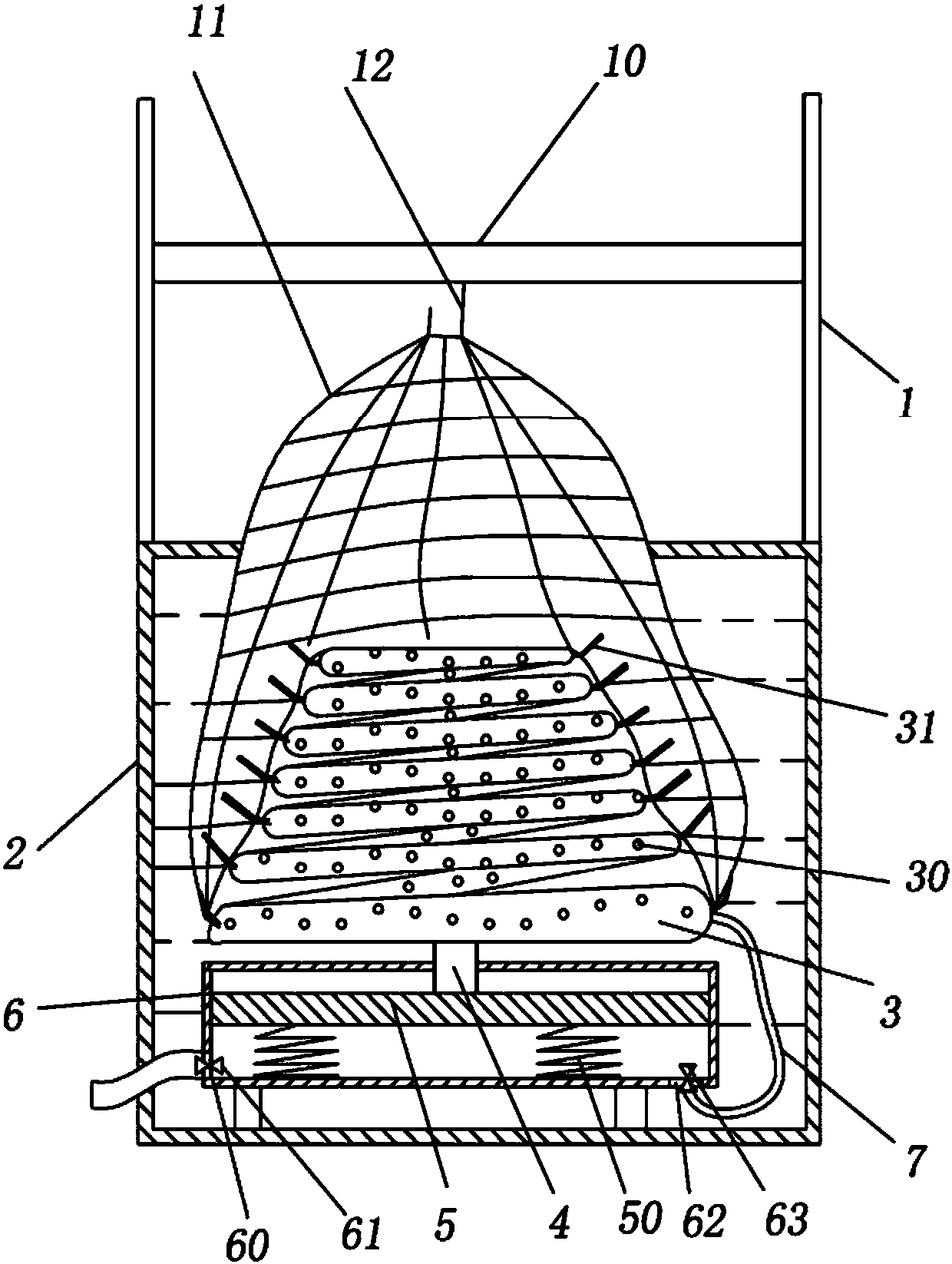

[0030] The embodiment is basically as attached figure 1 Shown: circuit board manufacturing method, comprises the following steps:

[0031] A. Putting on the shelf: put the substrate that needs to be desmeared into the hanging basket, and fix the hanging basket on the walking frame 10 with a hook 12; the hanging basket is a flexible mesh basket 11; a deformable net made of PVC material is preferred Shape basket 11, walking frame 10 is vertically slidably connected with frame 1.

[0032] B. Leavening: Put the mesh basket into the medicine tank with leavening agent and react for 3 minutes.

[0033] C. Water washing: wash the bulky substrate with deionized water, and wash twice.

[0034] D, glue removal: put the mesh basket into the glue removal device, and react for 1min; the glue removal device includes a casing 2 for loading glue remover, and the glue remover is preferably potassium permanganate solution in the present embodiment , the box body 2 is provided with a support c...

Embodiment 2

[0043] The difference between this embodiment and embodiment 1 is:

[0044] The bulking reaction time in step B is 2 minutes; the reaction time for desmearing in step D is 3 minutes; the neutralization reaction time in step F is 3 minutes.

Embodiment 3

[0046] The difference between this embodiment and embodiment 1 is:

[0047] The bulking reaction time in step B is 3 minutes; the reaction time for removing smear in step D is 5 minutes; the neutralization reaction time in step F is 3 minutes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com