Bend-resistant cable for coal cutter

A shearer, bending-resistant technology, applied in the direction of bendable cables, insulated cables, bendable conductors, etc., can solve the problems of control wire core breakage, control wire core easily broken core, equipment stoppage, etc. The effect of low temperature resistance, improving production efficiency and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in further detail below through specific implementation examples and in conjunction with the accompanying drawings.

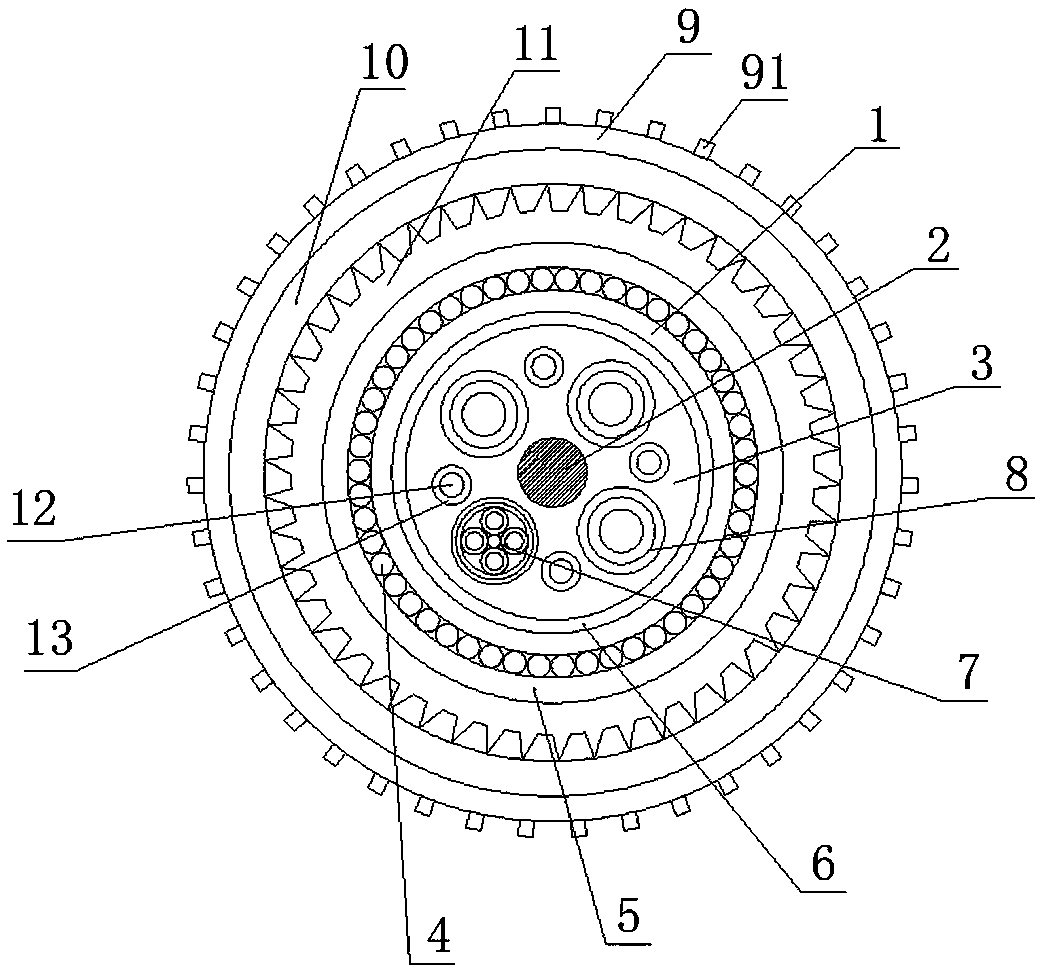

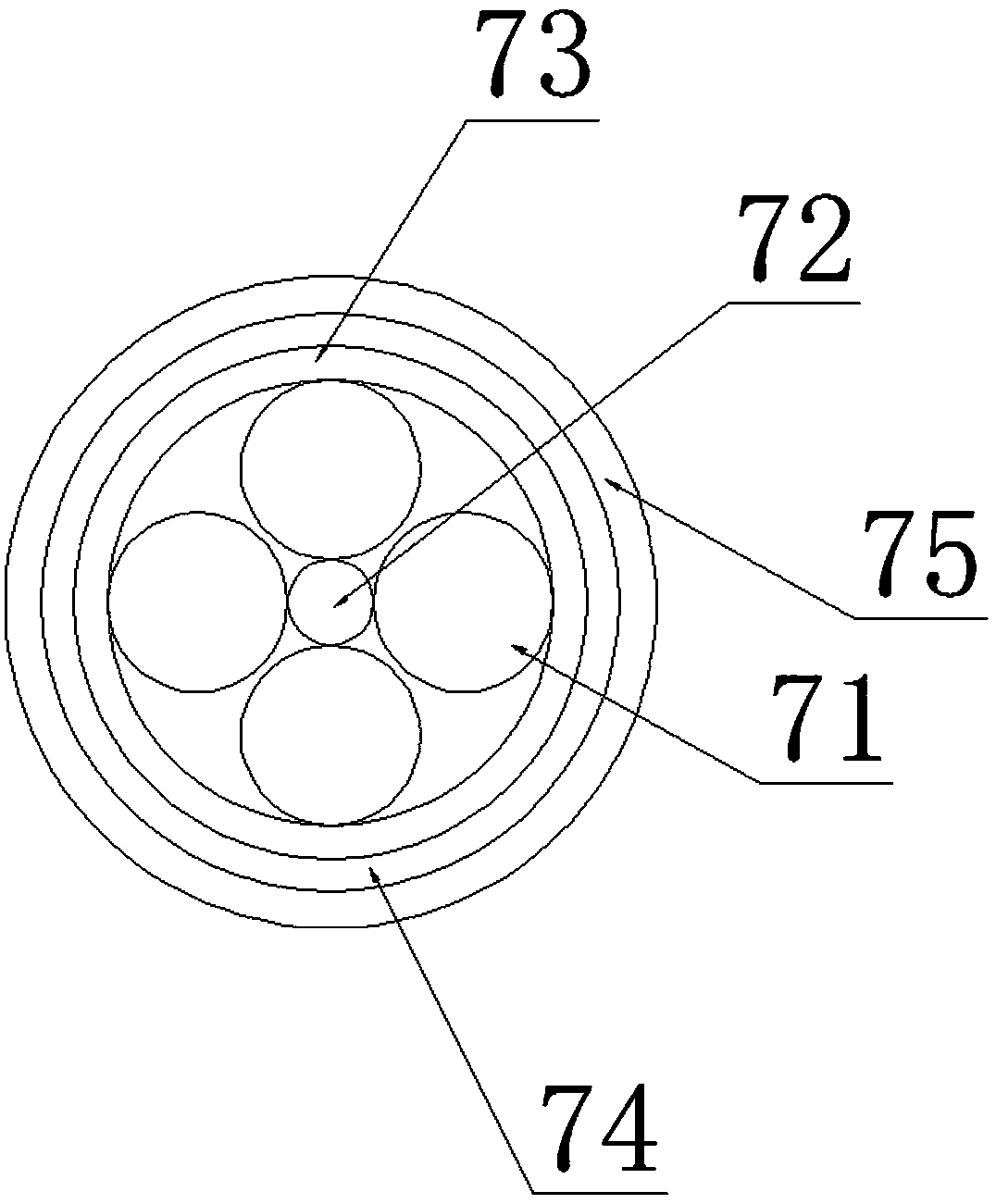

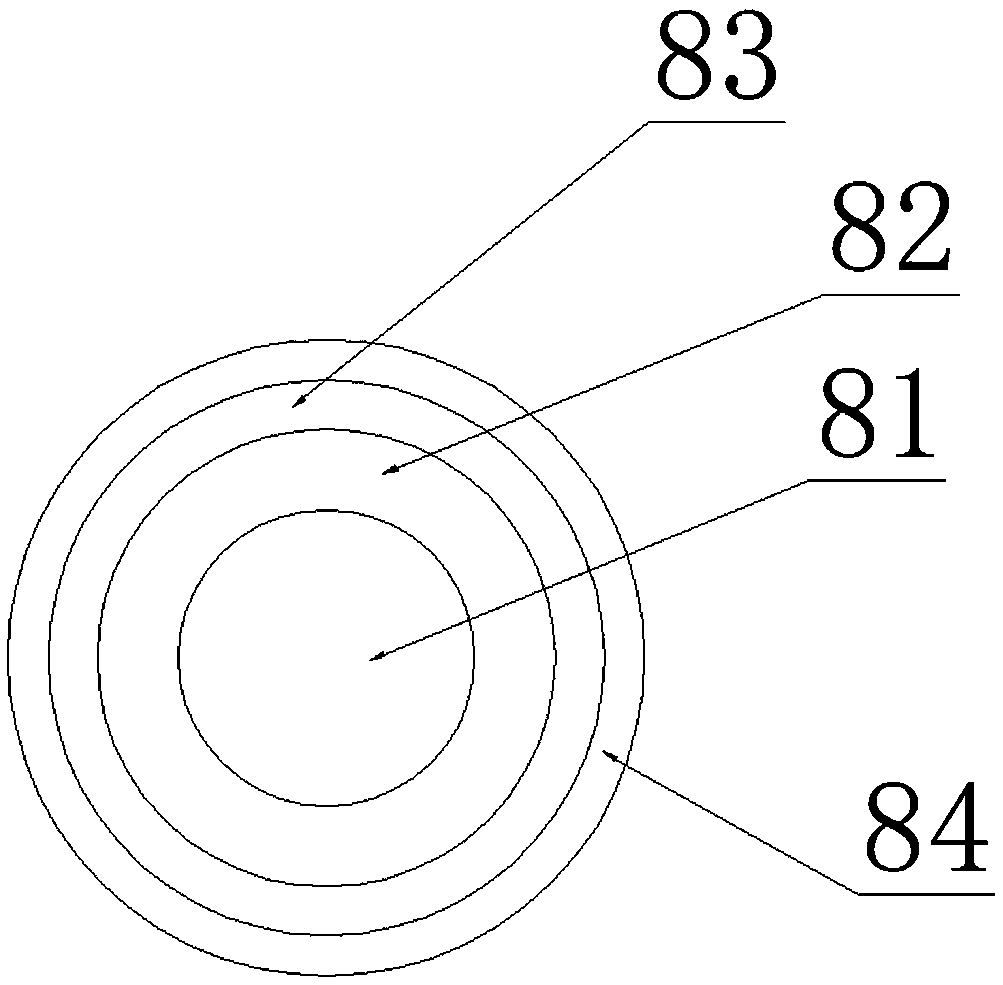

[0022] Figure 1-3 Shown is the bending-resistant shearer cable provided by the present invention, including three power cable cores 8, ground wire core 2, control wire core 7 and filling layer 3; the three power cable cores 8, ground wire core 2 and control The wire core 7 is arranged in the filling layer 3; the filling layer 3 is provided with a plurality of carbon fiber composite core wires 12, and each carbon fiber composite core wire 12 is bundled by a plurality of carbon fiber filaments, and each carbon fiber composite core wire 12 The outer layer is wrapped with an insulating tube 13; the filling layer 3 is covered with a CPP tightening tape layer 6; the CPP tightening tape layer 6 is sequentially provided with an oxygen barrier layer 1, a heat insulation layer 4, and a steel belt layer 5 , non-magnetic bar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com