Vacuum retaining structure for high-resolution quartz flexible accelerometer

An accelerometer and high-resolution technology, which is applied in the field of sensors, can solve the problems of reduced resolution and stability, reduced accelerometer accuracy, and inability to clean up, so as to achieve the effects of suppressing the gas output rate, maintaining stability, and maintaining vacuum

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

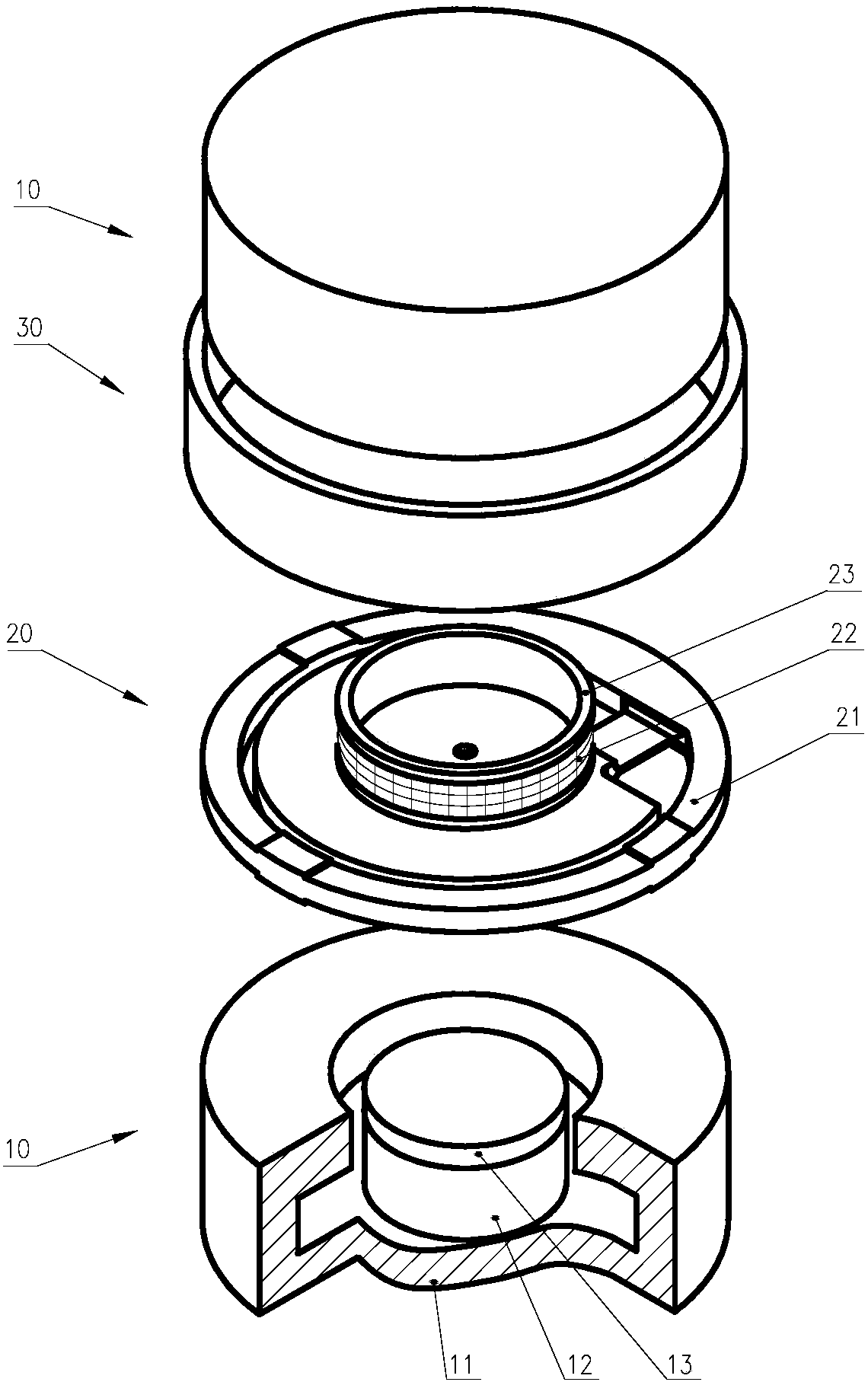

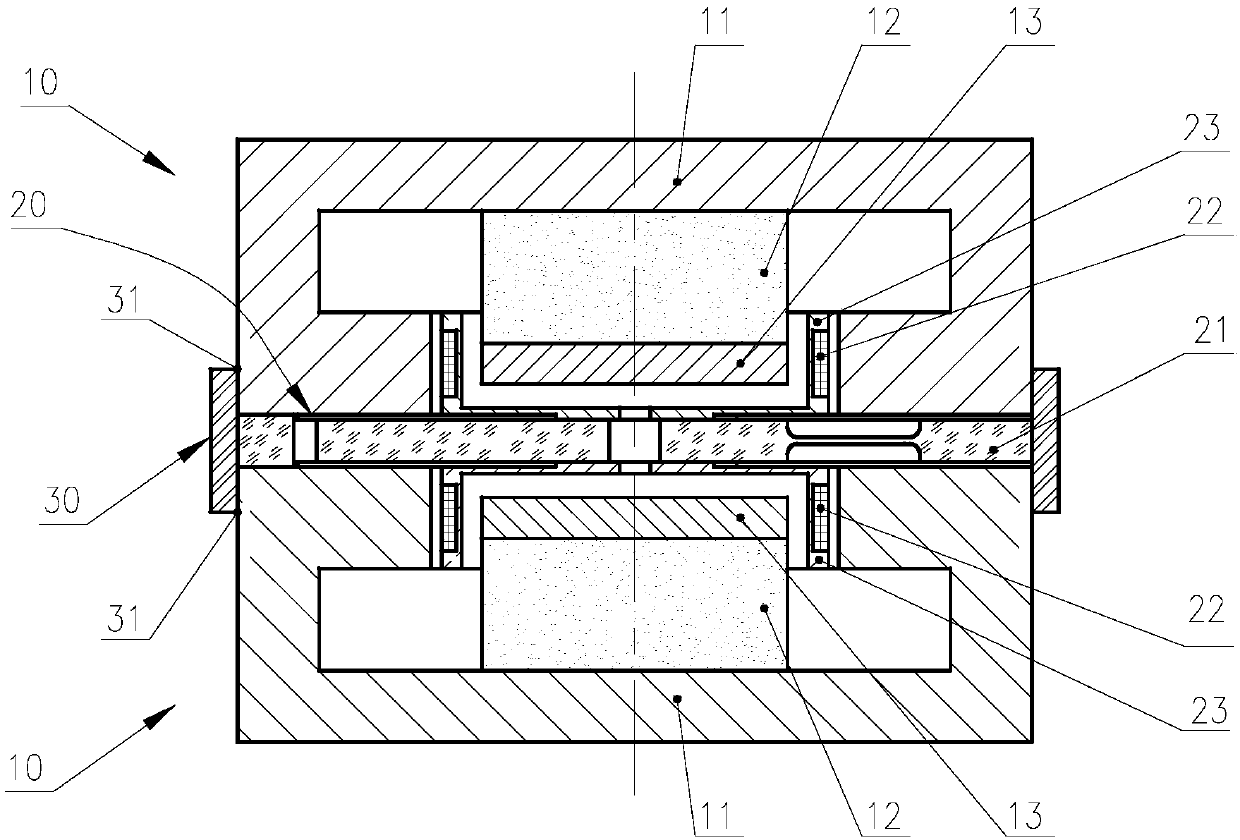

[0028] Embodiment one: if image 3 As shown, the upper and lower magnetic ring components are composed of magnetic ring 11, cylindrical permanent magnet 12, magnetic cap 13, magnetic cover 14 and magnetic base 15, which are coaxially installed in sequence based on the magnetic base A cylindrical permanent magnet, a magnetically permeable cap, a magnetically permeable cover, and a magnetically permeable ring constitute components of the magnetically permeable ring. The magnetic conduction ring is an annular structure, and a central hole is coaxially formed in its center. The bottom of the magnetic conduction ring is coaxially installed on the magnetic conduction cover, and the center of the magnetic conduction cover is coaxially made with a groove that protrudes upwards and opens downward. The central hole of the magnetic conduction ring is the same as the groove of the magnetic conduction cover. axis settings. The interior of the groove is coaxially arranged with a magnetic ...

Embodiment 2

[0029] Embodiment two: if Figure 4 As shown, the upper and lower magnetically permeable ring components are composed of a magnetically permeable ring 11, a cylindrical permanent magnet 12, a magnetically permeable cover 14 and a magnetically permeable base 15. Taking the magnetically permeable base as a reference, the cylindrical permanent magnet, The magnetically permeable cover and the magnetically permeable ring constitute components of the magnetically permeable ring. The magnetic conduction ring is an annular structure, and a central hole is coaxially formed in its center. The bottom of the magnetic conduction ring is coaxially installed on the magnetic conduction cover, and the center of the magnetic conduction cover is coaxially made with a groove that protrudes upwards and opens downward. The central hole of the magnetic conduction ring is the same as the groove of the magnetic conduction cover. The shaft is set, and the interior of the groove is coaxially arranged w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com