Pipeline inner wall detection system and method

A detection system and pipeline technology, applied in measuring devices, instruments, using wave/particle radiation, etc., can solve problems such as leakage of transmission materials, casualties, environmental pollution, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

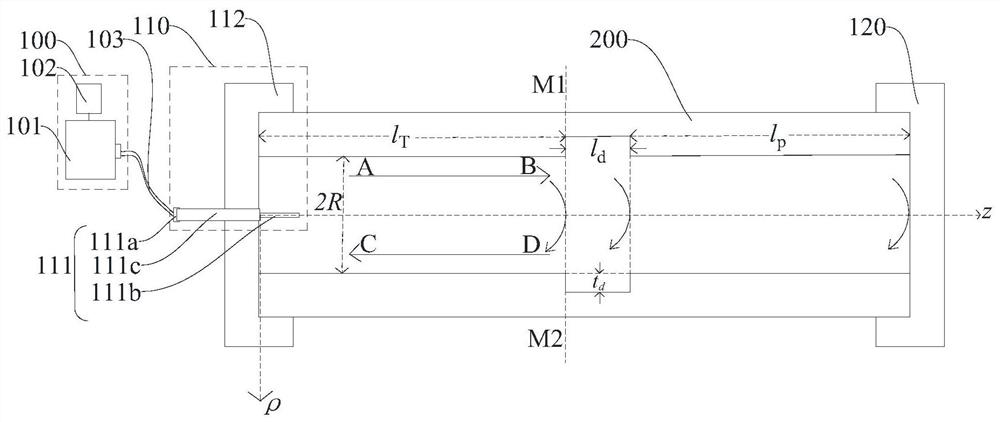

[0025] Please refer to figure 1 , this embodiment provides a detection system for the inner wall of a pipeline, which may include: a vector network analyzer device 100 and a coaxial feeding end cap device 110 . The input end of the coaxial feeding end cap device 110 is connected to the vector network analyzer device 100 , and the output end of the coaxial feeding end cap device 110 is used to connect to one end of the pipeline 200 to be tested.

[0026] The vector network analyzer device 100 is used to output microwaves and transmit the microwaves to the coaxial feeding end cover device 110 . Microwaves can be electromagnetic waves with a frequency of 300MHz to 300GHz, which is an abbreviation for a limited frequency band in radio waves.

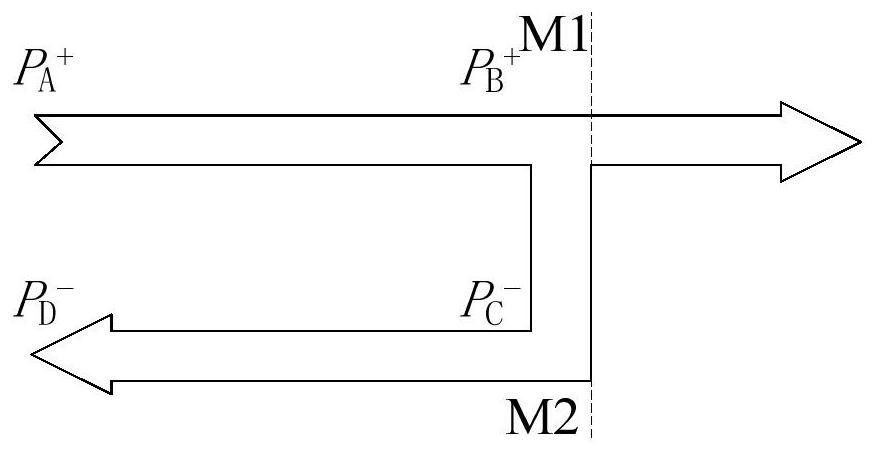

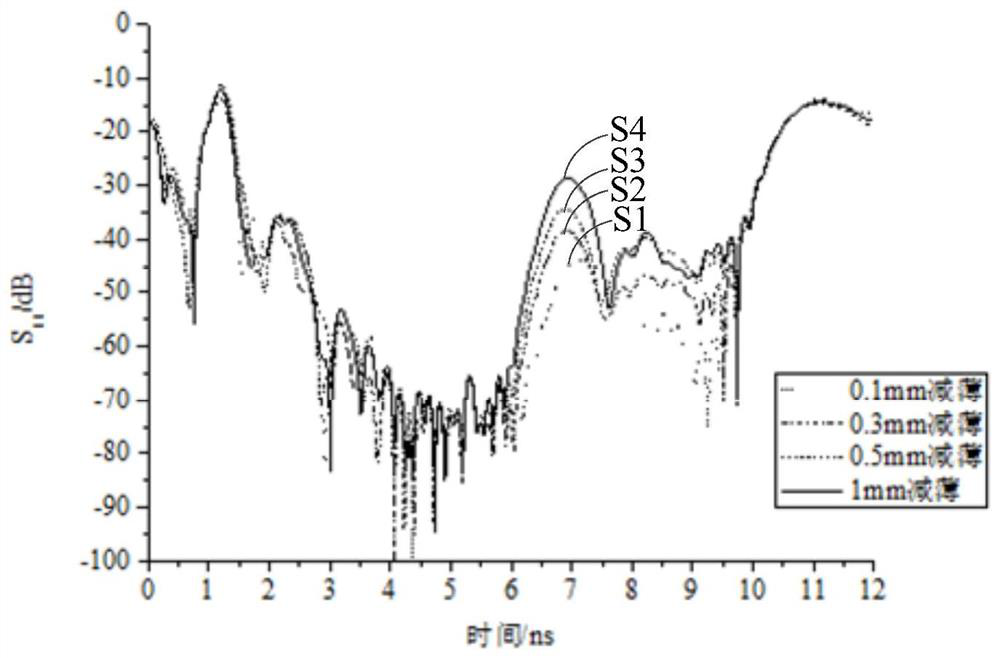

[0027] The coaxial feeding end cover device 110 is used to propagate the received microwaves into the pipe to be tested 200, and when the inner wall of the pipe to be tested 200 is thinned, receive the microwaves through The echo signal re...

no. 2 example

[0101] see Figure 4 , the example of the present invention provides a method for detecting the inner wall of a pipeline, which is applied to the above-mentioned system, and the method may include:

[0102] Step S400: the vector network analyzer device outputs microwaves and transmits the microwaves to the coaxial feeding end cover device;

[0103] Step S410: The coaxial feeding end cover device propagates the received microwave into the pipeline to be tested, and when the inner wall of the pipeline to be tested is thinned, receives the microwave through the The echo signal reflected by the thinning part of the inner wall of the pipeline to be tested;

[0104] Step S420: the coaxial feed end cover device also transmits the received echo signal to the vector network analyzer device;

[0105] Step S430: The vector network analyzer device further processes the echo signal to obtain thinning information of the thinning part of the inner wall of the pipeline to be tested.

[010...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com