Mixed-connection post-tensioned prestressing assembly concrete frame system and construction method thereof

A post-tensioning prestressing, hybrid connection technology, applied in building components, building insulation materials, earthquake-proof, etc., can solve the problems of low structural robustness, high cost of energy-consuming steel bars, and difficult transportation and hoisting, and achieves a reduction in technology. Difficulty, good seismic performance, and the effect of improving the level of green construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

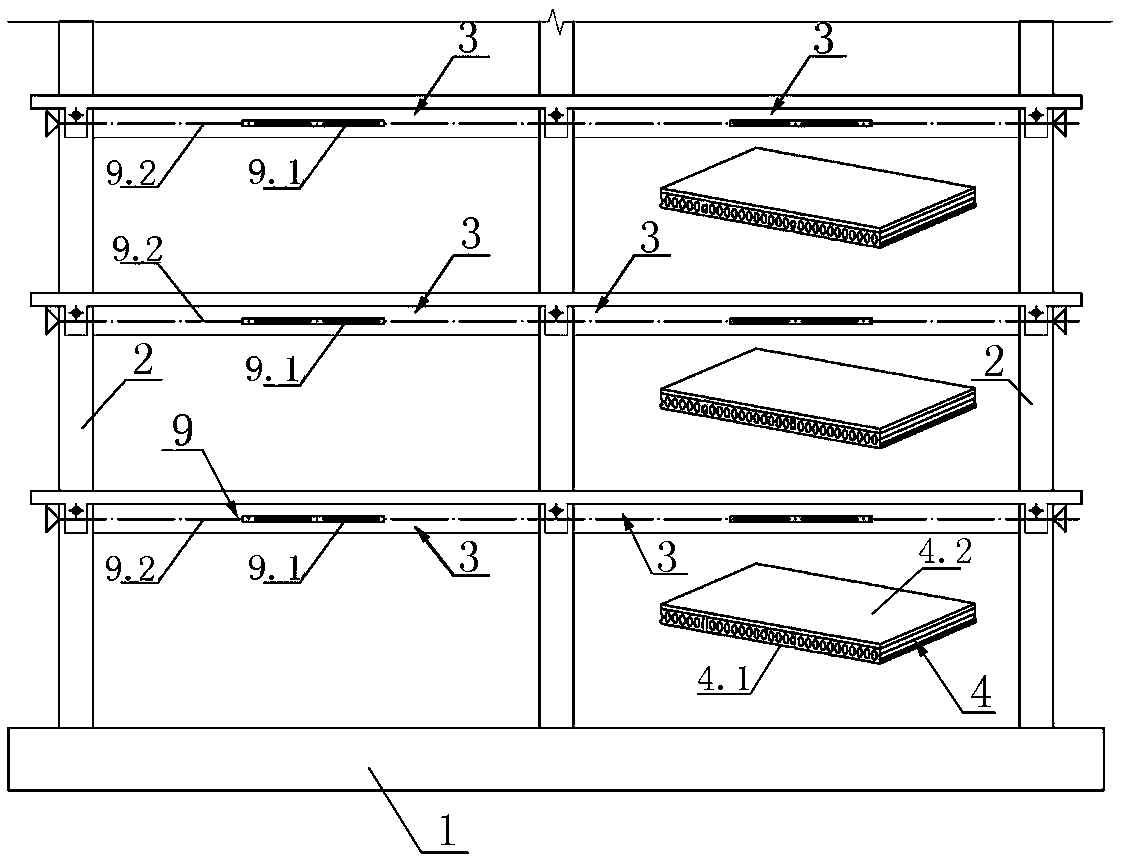

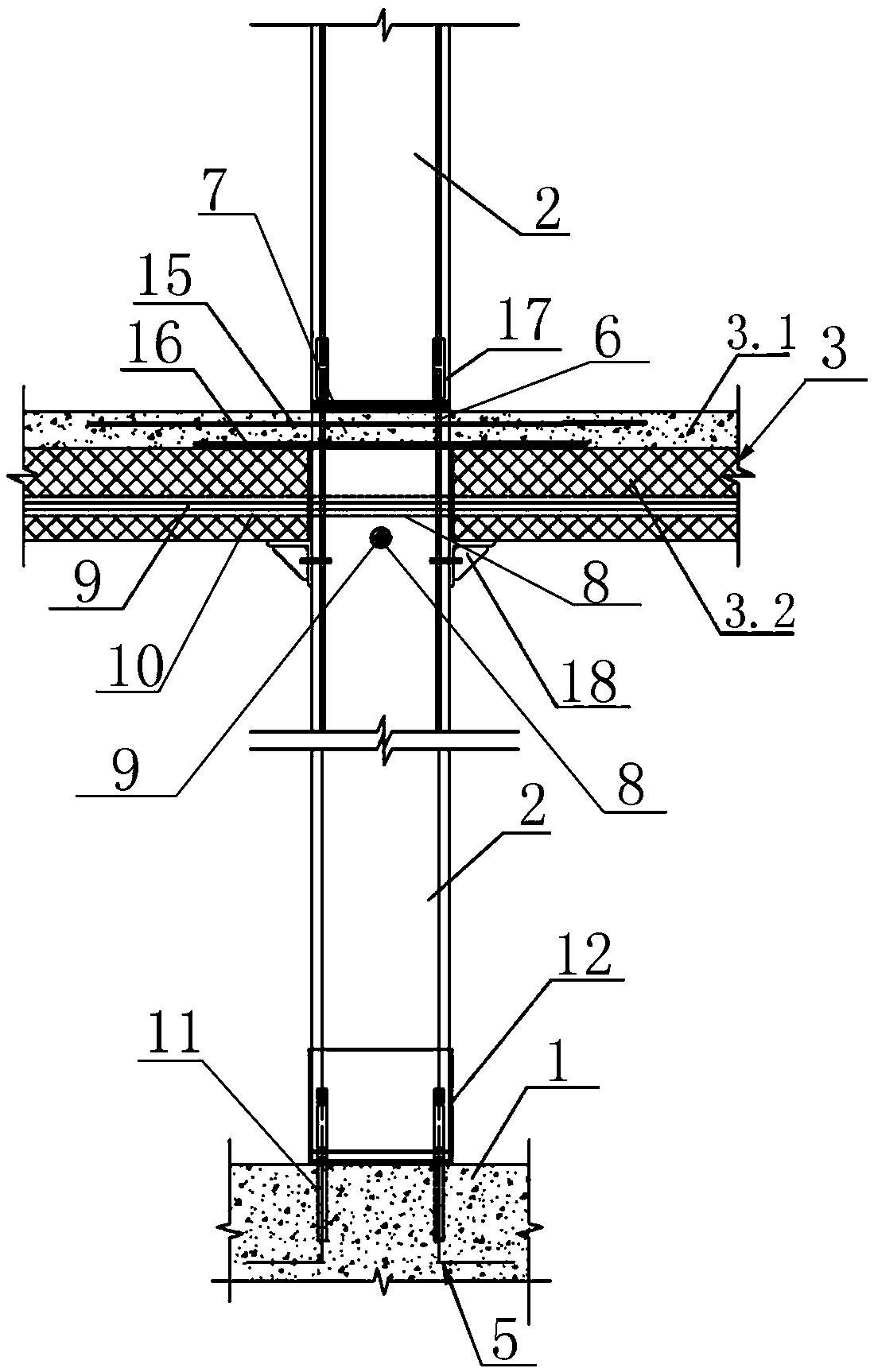

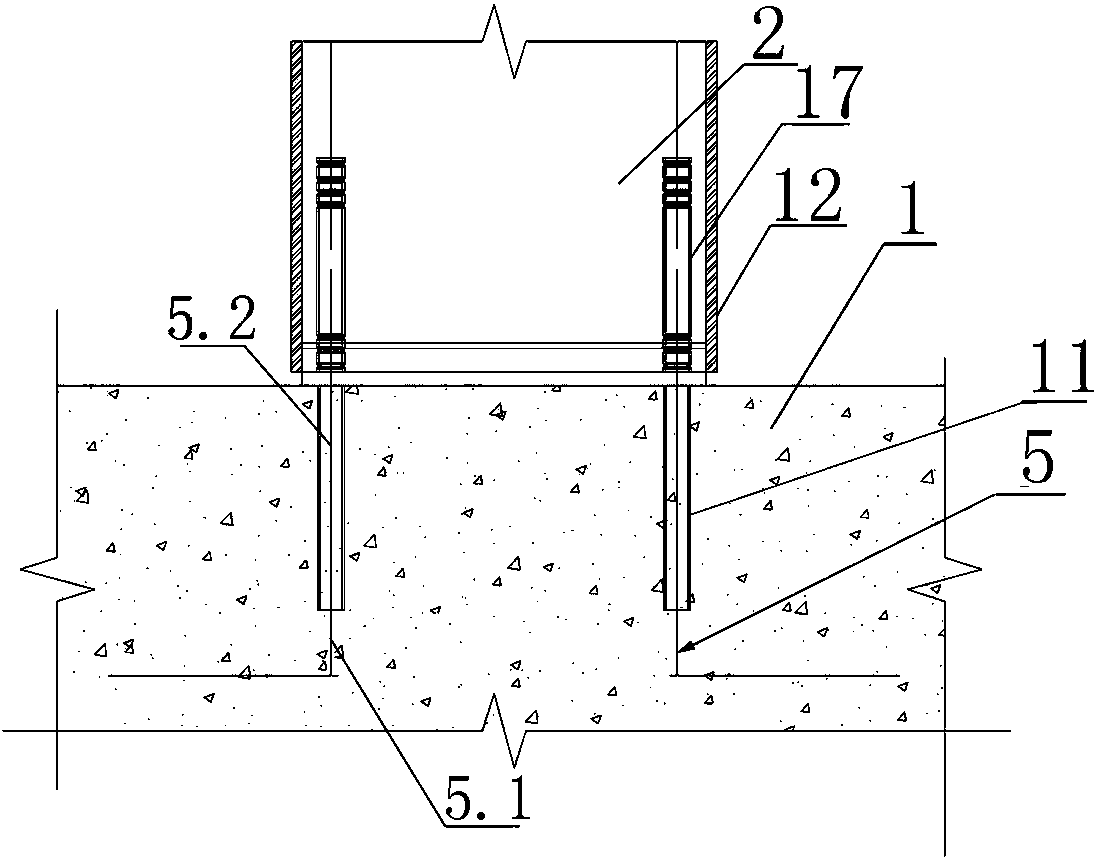

[0055] Such as Figure 1-10 As shown, this mixed-connected post-tensioned prestressed assembled concrete frame system includes a foundation 1, frame columns 2, frame beams 3 and floor slabs 4; Steel bar 5; the connecting steel bar 5 is L-shaped, including a vertical side and a horizontal side connected to the bottom end of the vertical side; the lower part of the vertical side and the horizontal side of the connecting steel bar 5 are buried in the foundation 1, and the connecting steel bar 5 The part in the buried foundation 1 includes the bonded section 5.1 of the connecting steel bar and the unbonded section 5.2 of the connecting steel bar; wherein, the unbonded section 5.2 of the connecting steel bar is located on the lower side of the top surface of the foundation 1, on the vertical edge close to one end of the foundation , and the length of the unbonded section 5.2 of the connecting steel bar is 3 to 20 times the diameter of the connecting steel bar 5, and the bonded sect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com