Transfer manipulator for forming machine

A molding machine and manipulator technology, which is applied to conveyor objects, transportation and packaging, etc., can solve the problems of restricted manipulator activity space and limited manipulator installation space, and achieve the effect of reducing occupancy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

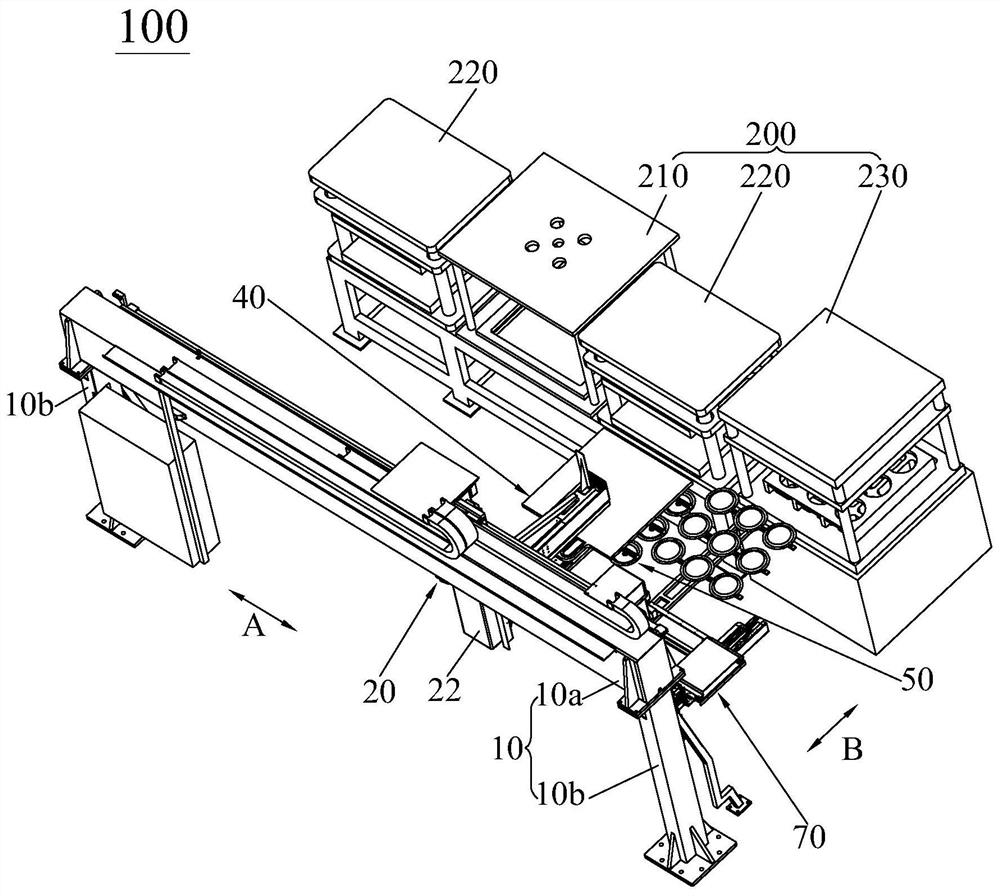

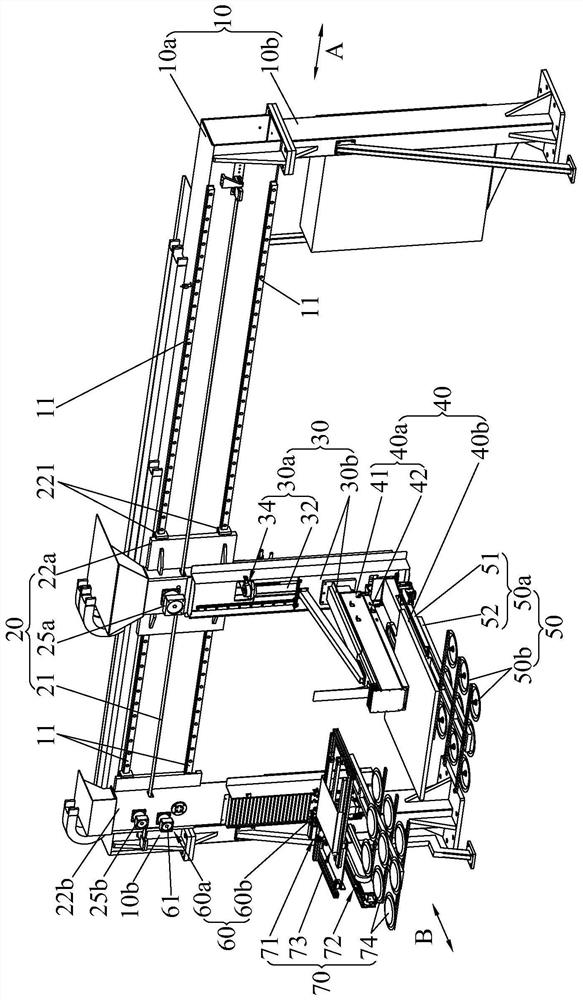

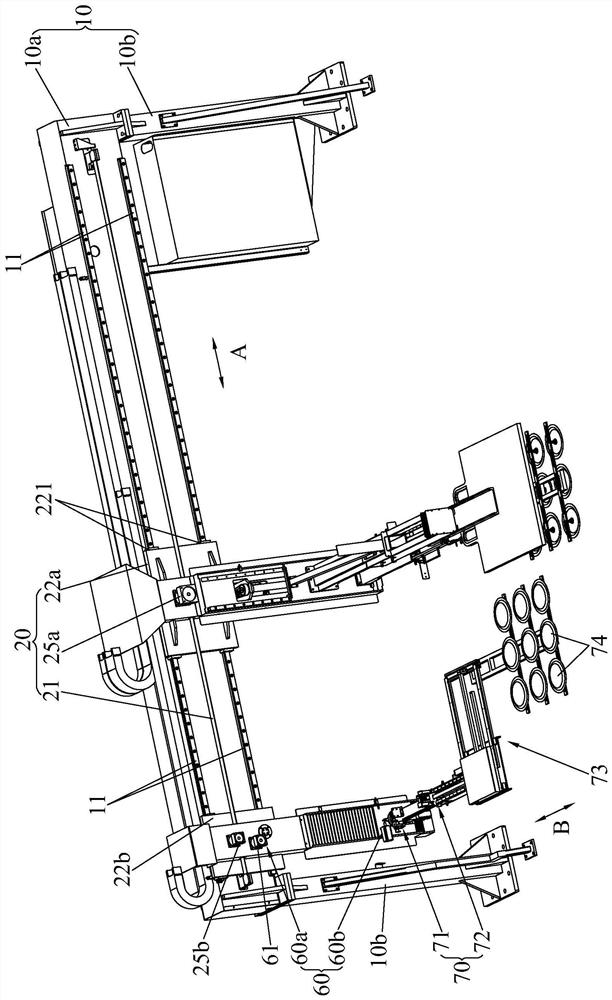

[0037] see Figure 1 to Figure 6 , the forming machine transfer manipulator 100 of the present invention is applicable to the first blank (such as the wet blank in the lunch box manufacturing process) and the second blank (such as the wet blank in the lunch box manufacturing process) in the forming machine 200 (such as the lunch box forming machine). dry base) to pick up and deliver, to grab the wet base formed by the wet base forming die 210 of the molding machine 200, and send the wet base that is taken away into the dry base forming die 220 of the forming machine 200, by the dry base The forming mold 220 performs drying treatment on the incoming wet billet to realize the conversion from the wet billet to the dry billet; finally, the dry billet in the dry billet forming die 220 is taken away and sent to the trimming die 230 of the forming machine 200, Finally, the product in the trimming mold 230 is taken away. Specifically, as figure 1 As shown, in the present embodiment,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com