Color tape slitting device with leader tape automatic sticking function

A technology of guide belts and ribbons, which is applied in metal processing and other directions, can solve problems such as low labor efficiency and complicated work procedures, and achieve the effects of saving labor costs, reducing relative friction, and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

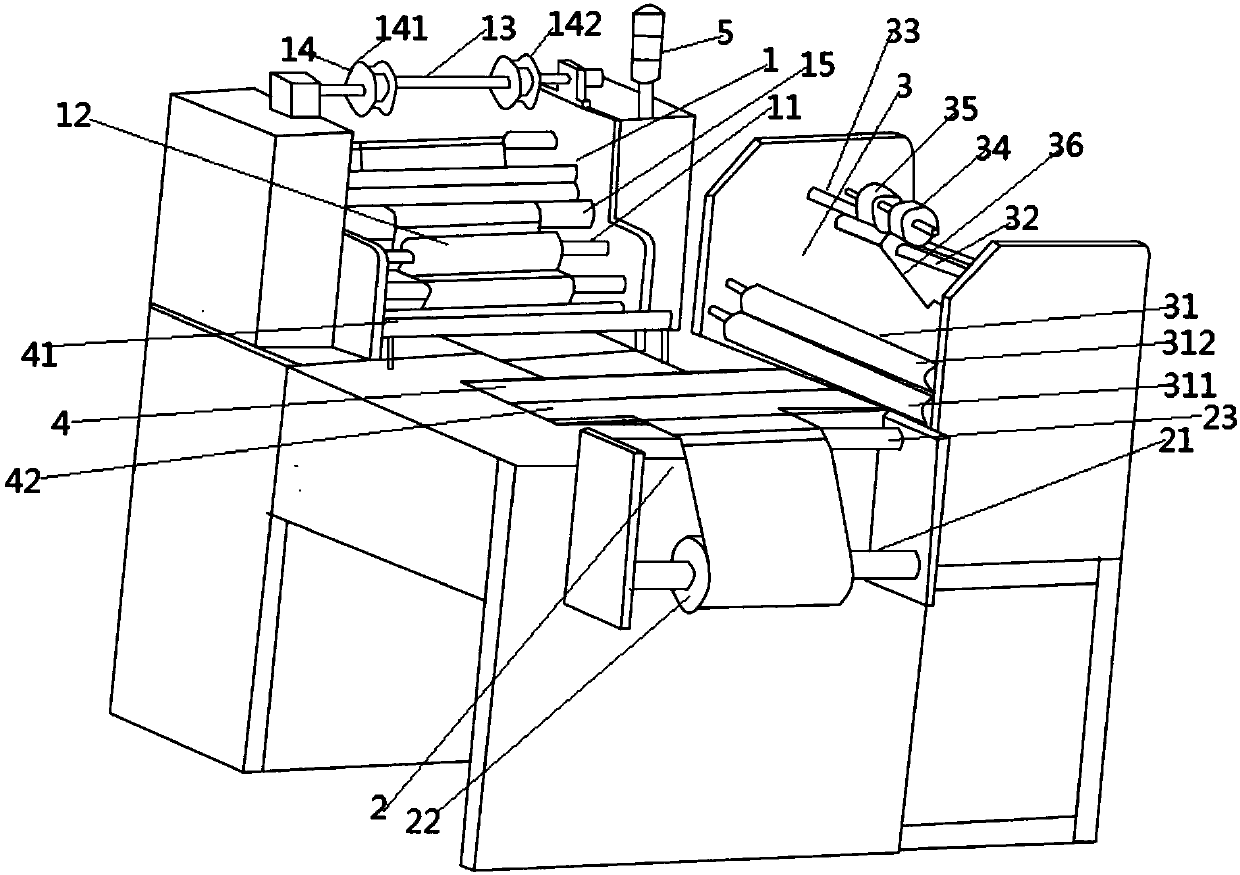

[0028] In order to achieve the purpose of the present invention, as figure 1 As shown, a ribbon cutting device with the function of automatically pasting the guide tape, including:

[0029] Small roll ribbon reel assembly 1: used for cutting the master ribbon 22 and rewinding the slit small roll ribbon, the small roll ribbon reel assembly is equipped with a film cutter assembly 11. An array of film cutters 12 is provided on the film cutter assembly 11, and the film cutter assembly 11 is in a cylindrical shape; one group, two groups, and three groups are also provided on the small roll ribbon coil assembly , four or more groups of receiving shafts (not shown); the film cutter combination 11 is cylindrical, which reduces the relative friction between the cutting device and the ribbon during work, and prolongs the film cutter The life of combination 11 further prolongs the life of the ribbon cutting device with the function of automatically pasting the guide tape;

[0030] Mast...

Embodiment 2

[0044] The rest are the same as the above-mentioned embodiment, the difference is that the ribbon cutting device with the function of automatically pasting the guide tape is also provided with a frequency converter to control the servo motor (not shown), and the frequency converter controls the servo motor ( not shown) is used to adjust the reverse tension of the master ribbon 22, the frequency converter controls the servo motor (not shown) and is electrically connected in series with the master ribbon feeding assembly 2, further avoiding the cutting device During processing, it is easy to break the ribbon because its tension is not easy to control.

[0045] With this technical solution, the structure of the ribbon cutting device with the function of automatically attaching the guide tape can also be used to cut the master roll of ribbon into small rolls of ribbon, the cutting device can easily control its tension, and at the same time reduce the The relative friction between ...

Embodiment 3

[0047] The rest is the same as the above-mentioned embodiment, the difference is that the ribbon cutting device with the function of automatically pasting the guide tape is also provided with a winding mechanism servo motor (not shown), and the winding mechanism servo motor ( not shown) is used to adjust the winding tension of the small roll of ribbon, the winding mechanism servo motor (not shown) is electrically connected in series with the small roll of ribbon coil assembly 1, further avoiding the cutting device in the During processing, it is easy to break the ribbon because its tension is not easy to control.

[0048] With this technical solution, the structure of the ribbon cutting device with the function of automatically attaching the guide tape can also be used to cut the master roll of ribbon into small rolls of ribbon, the cutting device can easily control its tension, and at the same time reduce the The relative friction between the cutting device and the ribbon ens...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com