Grinding head lining plate with reinforcing rib

A technology of reinforcing ribs and grinding heads, applied in grain processing and other directions, can solve the problems of affecting the production efficiency of the tube mill, increasing the operating cost of the tube mill, and the wear of the lining board, so as to protect the lining board of the grinding head and reduce the operating cost. , the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

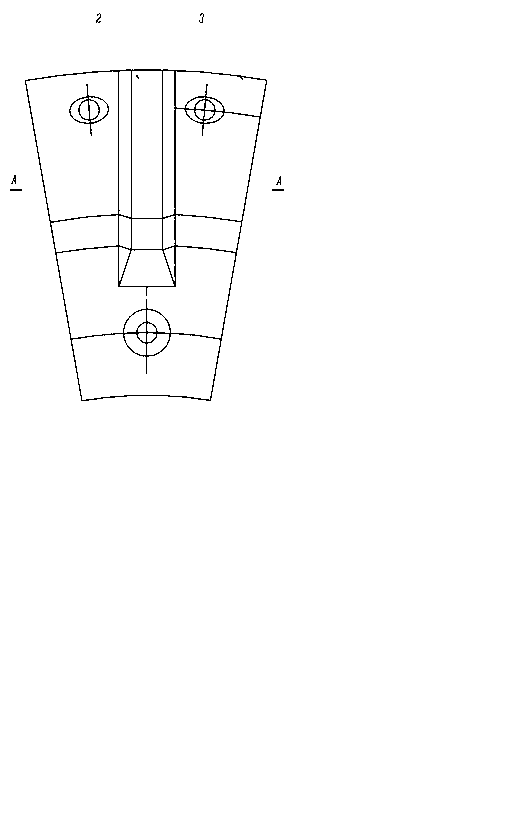

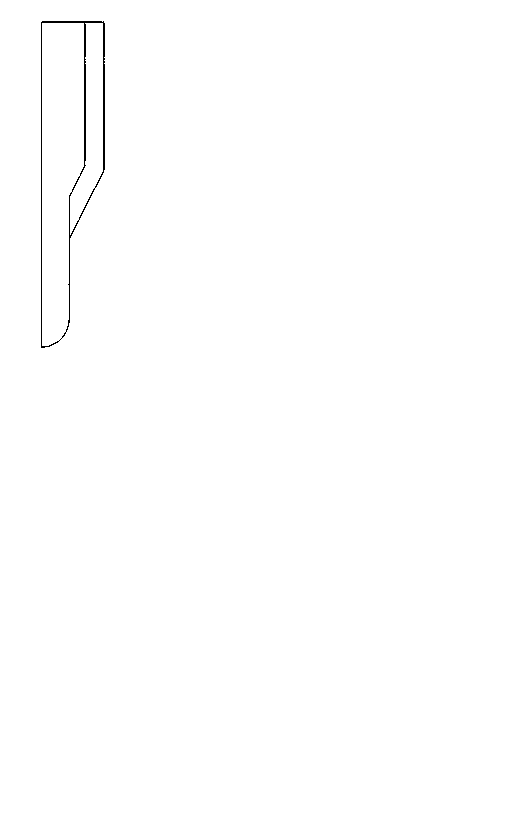

[0017] A grinding head liner with reinforcing ribs, including mounting screw holes, the surface of the grinding head liner 3 is provided with trapezoidal reinforcing ribs 2, the size of the upper opening of the trapezoidal reinforcing rib 2 is 20 mm, the size of the lower opening is 20 mm, and the thickness is 10 mm. The angle between the two sides of the trapezoid is 15 degrees.

Embodiment 2

[0019] A grinding head liner with reinforcing ribs, including mounting screw holes, the surface of the grinding head liner 3 is provided with trapezoidal reinforcing ribs 2, the size of the upper opening of the trapezoidal reinforcing rib 2 is 30 mm, the size of the lower opening is 80 mm, and the thickness is 20 mm. The angle between the two sides of the trapezoid is 30 degrees.

Embodiment 3

[0021] A grinding head liner with reinforcing ribs, including mounting screw holes, the surface of the grinding head liner 3 is provided with trapezoidal reinforcing ribs 2, the size of the upper opening of the trapezoidal reinforcing rib 2 is 50 mm, the size of the lower opening is 120 mm, and the thickness is 40 mm. The angle between the two sides of the trapezoid is 90 degrees.

[0022] The present invention designs a trapezoidal reinforcing rib on the working face of the grinding head without changing the installation size of the original grinding head liner. The steel ball rotates to the highest point and then hits the material for crushing and grinding. The reinforcing ribs can reduce the relative friction between the steel ball and the grinding head liner and protect the grinding head liner. The convex ribs of the ribs also lift the grinding body when the tube mill rotates, and change the original trajectory of the grinding body, effectively reducing the relative fricti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com